Injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to produce a variety of products. The choice of plastic material is critical as it influences the properties and applications of the final product. Here are some of the most common materials used in injection molding, along with their key properties and typical applications.

Acrylonitrile Butadiene Styrene (ABS)

ABS is known for its strength, toughness, and high impact resistance. It offers excellent surface finish and is easy to mold, making it suitable for detailed and complex parts.

Automotive Parts: ABS is used in making dashboards, wheel covers, and interior components.

Consumer Electronics: Housings for devices such as computers, televisions, and smartphones.

Household Goods: Commonly found in products like toys and kitchen appliances.

Polypropylene (PP)

Polypropylene is lightweight and has good chemical and fatigue resistance. It is also flexible and has a low density, which makes it ideal for various applications.

Packaging: Widely used in containers, caps, and packaging films.

Automotive: Used in bumpers, fender liners, and battery cases.

Medical Devices: Ideal for syringes, diagnostic devices, and laboratory equipment.

Polyethylene (PE)

Polyethylene offers versatility with different densities such as LDPE and HDPE. It is known for its excellent chemical and moisture resistance, making it suitable for a variety of uses.

Packaging: Commonly used for bottles, containers, and plastic bags.

Consumer Goods: Used in toys, housewares, and sporting goods.

Agriculture: Utilized in irrigation pipes, greenhouse covers, and tanks.

Our Services

- Material Selection: We help you choose the best material based on your product requirements.

- Design Optimization: Our engineers work with you to optimize your design for manufacturability.

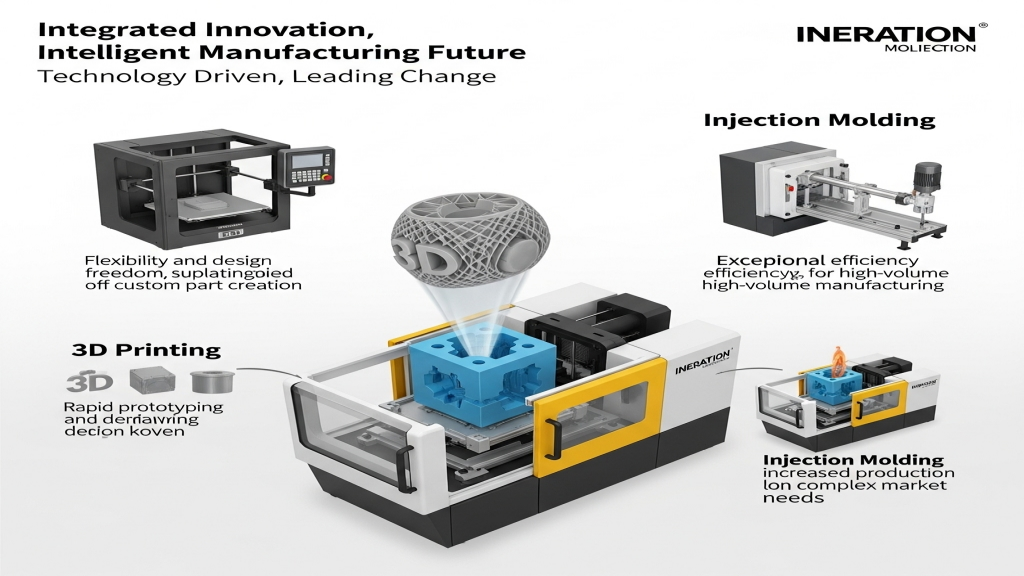

- Rapid Prototyping: Validate your designs with our quick and efficient prototyping services.

- Quality Assurance: We ensure that every product meets the highest standards of quality.

- Timely Delivery: Our efficient production processes and logistics ensure that your orders are delivered on time, every time.

Conclusion

At Ruicheng, we provide comprehensive injection molding services, from material selection to final production. Our team of experienced engineers is ready to assist you in choosing the right material and optimizing your design for manufacturing. We offer rapid prototype services to help validate your designs and ensure they meet all functional requirements before full-scale production. For more information or to discuss your project, please contact us. We look forward to working with you to bring your ideas to life.