Introduction

Acetal materials, with their excellent mechanical properties and wear resistance, are widely used in precision component manufacturing. In today’s competitive market, fast molding not only shortens delivery cycles but also demonstrates a company’s ability to respond quickly to customer needs.In injection molding production, fast molding technology helps companies reduce development costs while maintaining product consistency and high performance. Efficient mold design and optimized processing workflows are the key to accelerating the launch of Acetal products.

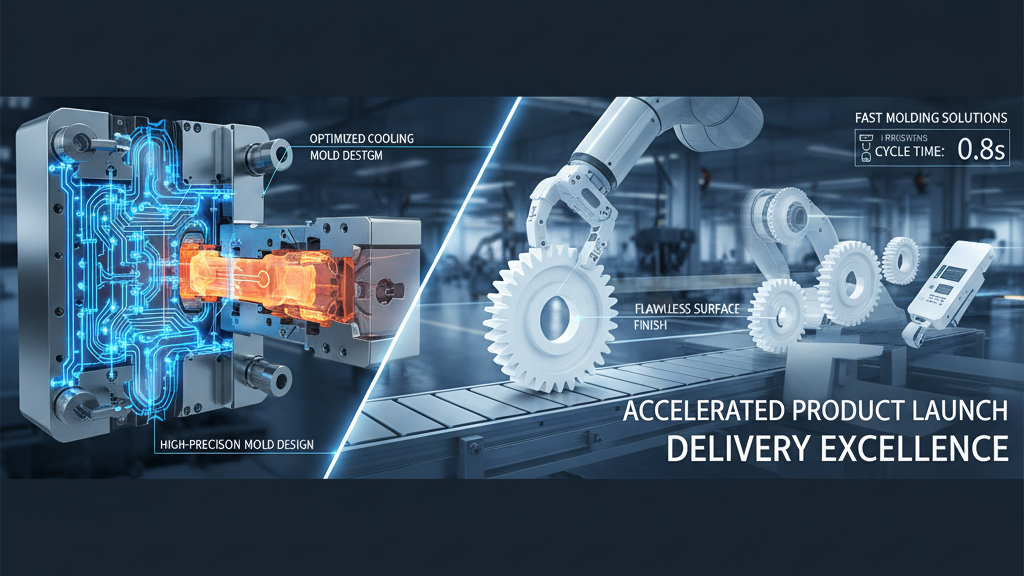

The processing of Acetal products requires extremely high precision in mold design. Optimized mold structures and cooling systems can significantly improve injection efficiency and reduce defect rates.Through innovative molding solutions, companies can not only boost production efficiency but also gain an advantage in customer delivery and market competition.

How Can Mold Structures Be Optimized to Speed Up Molding?

The speed of molding Acetal products is directly influenced by the rationality of the mold structure. By adopting simplified runner designs and efficient cooling solutions, cycle times can be effectively reduced.Additionally, the choice of mold steel and surface treatment processes can impact both mold durability and production cycles.

- Simplified Runner Design: Reduces resistance and improves filling efficiency.

- Cooling System Optimization: Enhances mold temperature control and shortens cooling time.

- [High-Performance Mold Steel](- Precise Temperature Control: Stabilizes melt flow behavior. "High-Performance Mold Steel"): Improves tool life and process stability.

- Surface Treatment Technology: Improves demolding efficiency and part appearance.

😊 Optimized mold structures allow Acetal products to enter production faster.

How Can Process Control Enable Fast Injection Molding?

Beyond fast mold opening, process control is equally critical for reducing production cycles. Precise control of temperature and pressure ensures stable melt flow and prevents defects.The coordination of injection speed, holding pressure, and cooling stages ultimately determines overall production efficiency.

- Precise Temperature Control: Stabilizes melt flow behavior.

- Efficient Injection Speed: Ensures rapid filling and reduces defects.

- Proper Holding Pressure: Minimizes internal stress and deformation.

- Uniform Cooling: Reduces warpage and dimensional deviations.

⚡ Scientific process control is the core of achieving fast Acetal injection molding.

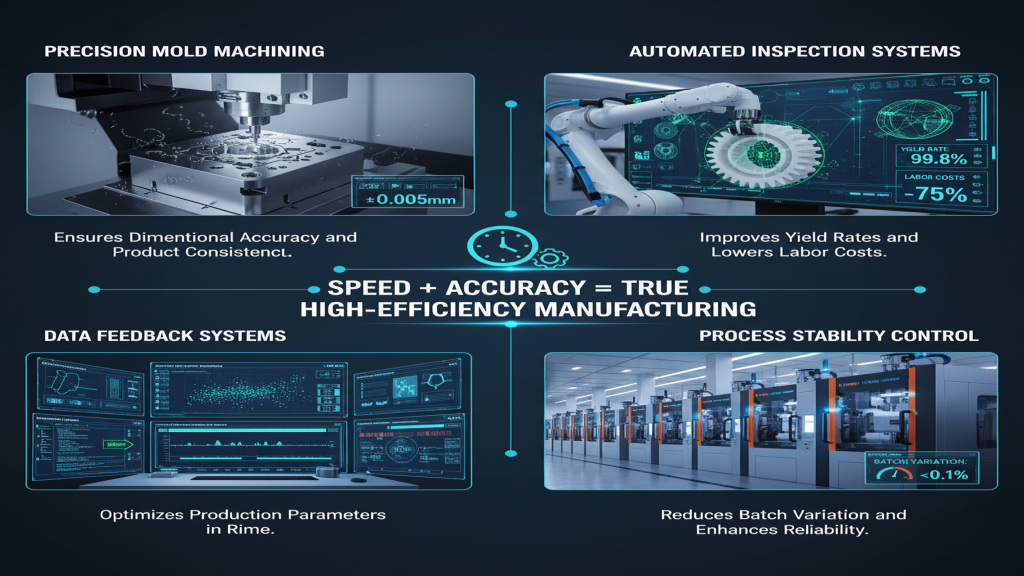

How Can Product Precision Be Guaranteed in Fast Production?

Fast molding and injection must deliver not only speed but also precision. High-precision mold machining and automated inspection systems are key to ensuring parts meet design requirements.Smart inspection and data feedback systems enable companies to achieve both quality and efficiency in high-speed production environments.

- Precision Mold Machining: Ensures dimensional accuracy and product consistency.

- Automated Inspection Systems: Improves yield rates and lowers labor costs.

- Data Feedback Systems: Optimizes production parameters in real time.

- Process Stability Control: Reduces batch variation and enhances reliability.

🔍 True high-efficiency manufacturing means achieving both speed and accuracy.

Fast Molding vs. Traditional Injection

| Comparison Item | Fast Molding | Traditional Injection | Application | Cost Impact |

|---|---|---|---|---|

| Mold Design | Simplified runners, efficient cooling | Standard structures | New product development | Lower cost |

| Cycle Time | Short, fast delivery | Long, less efficient | Mass production | Longer cycle |

| Product Precision | High, stable output | Medium, needs adjustment | Precision parts | Requires extra steps |

| Equipment Setup | Optimized machines | Conventional equipment | Custom production | Lower initial |

How Fast Molding Improves Overall Efficiency

Fast molding of Acetal products is not only a technical advancement but also a key market strategy. By shortening delivery times, companies can quickly meet customer demands and strengthen loyalty.In production, efficiency improvements directly translate into cost reductions and higher profit margins.

1.Market Responsiveness: Rapidly meet project requirements.

2.Cost Optimization: Shorter cycles reduce labor and energy costs.

3.Customer Satisfaction: Faster delivery increases cooperation opportunities.

4.Competitive Advantage: Technical leadership brings more orders.

Conclusion

Fast molding and injection of Acetal products represent a dual challenge of efficiency and quality. Through optimized mold design, strict process control, and intelligent inspection, companies can achieve efficient and stable production.This approach not only reduces overall manufacturing costs but also strengthens market competitiveness. Ultimately, it empowers companies to stand out in the highly competitive manufacturing industry.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!