(picture from https://www.ferriot.com/blog/gas-assist-injection-molding/)

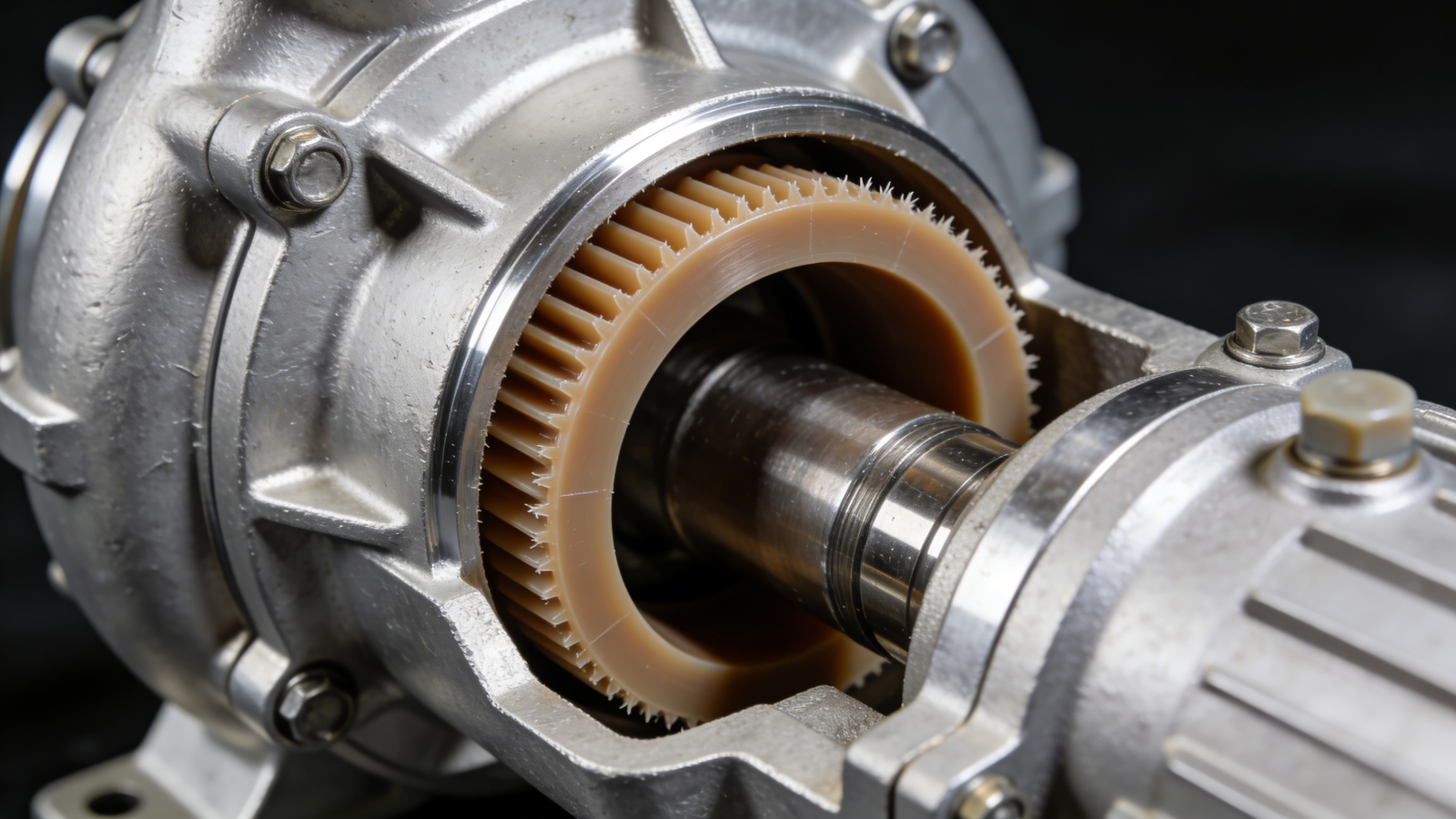

Gas Assist Injection Molding (GAIM) is an advanced manufacturing technique that improves the efficiency, quality, and structural integrity of plastic parts. This process involves injecting an inert gas, usually nitrogen, into the molten plastic within the mold cavity. The gas creates hollow sections, reduces material usage, and enhances part strength while minimizing defects like sink marks and warping.

This method is widely used in automotive, furniture, and industrial applications where lightweight yet strong plastic parts are required. Let’s explore how Gas Assist Injection Molding works and why it’s beneficial.

How Does Gas Assist Injection Molding Work?

(picture from https://www.ferriot.com/blog/gas-assist-injection-molding/)

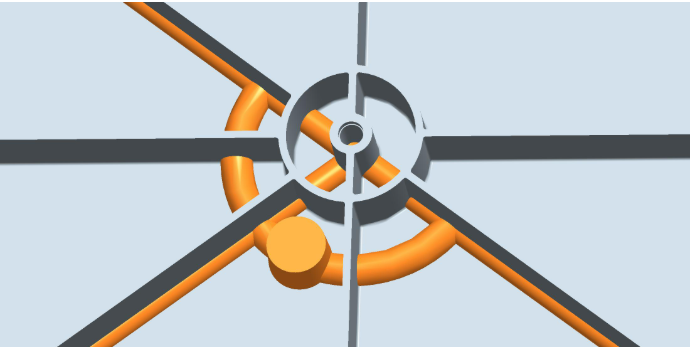

Gas Assist Injection Molding involves injecting pressurized gas into partially filled mold cavities, allowing the gas to push the molten plastic into the mold’s contours. This technique creates hollow sections in thicker areas, reducing weight while maintaining strength.

The Gas Assist Process:

- Plastic Injection – Molten plastic is injected into the mold but does not completely fill the cavity.

- Gas Injection – High-pressure nitrogen gas is introduced into the plastic through special channels.

- Plastic Displacement – The gas pushes the remaining molten plastic to the edges of the mold, ensuring complete cavity filling.

- Cooling and Solidification – The part cools, with the gas maintaining pressure to prevent shrinkage and defects.

- Ejection – The finished part is removed, now with reinforced hollow sections.

By utilizing gas pressure to assist with cavity filling, this method optimizes material distribution, reducing stress and cycle times.

What Are the Key Benefits of Gas Assist Injection Molding?

Gas Assist Injection Molding offers multiple advantages over traditional injection molding, including reduced material costs, improved part quality, and faster production cycles.

Benefits of GAIM:

- Material Savings – Reduces plastic usage by creating hollow sections in thick-walled areas.

- Lighter Parts – Produces strong yet lightweight components ideal for structural applications.

- Reduced Sink Marks and Warping – Internal gas pressure helps maintain uniform wall thickness, eliminating common defects.

- Shorter Cycle Times – Faster cooling and solidification reduce overall production time.

- Enhanced Aesthetic and Surface Quality – Creates smooth surfaces with minimal imperfections.

Where Is Gas Assist Injection Molding Used?

Gas Assist Injection Molding is widely used in industries that require lightweight, structurally sound, and visually appealing plastic parts. The process is particularly beneficial for producing large, complex components that would otherwise require excess material.

Common Applications:

- Automotive Parts – Door handles, instrument panels, seat frames, and structural reinforcements.

- Furniture Components – Chair arms, frames, and lightweight support structures.

- Appliances & Consumer Goods – Handles, casings, and housings for electronics and home products.

- Industrial Equipment – Large enclosures, tool casings, and machine parts.

This technique ensures cost-effective, high-quality manufacturing in applications where strength and weight reduction are critical.

Comparison of Gas Assist vs. Traditional Injection Molding

| Feature | Gas Assist Injection Molding | Traditional Injection Molding |

|---|---|---|

| Material Usage | Reduced, thanks to hollow sections | Higher, as entire cavity is filled |

| Part Weight | Lighter | Heavier due to solid plastic sections |

| Sink Mark Reduction | Eliminated | Common in thick areas |

| Cycle Time | Faster due to even cooling | Longer due to thick sections cooling slower |

| Structural Strength | High, reinforced with gas pressure | Good but with more material usage |

Key Considerations for Implementing Gas Assist Injection Molding

- Design for Gas Channels – Molds must incorporate dedicated gas pathways for uniform plastic displacement.

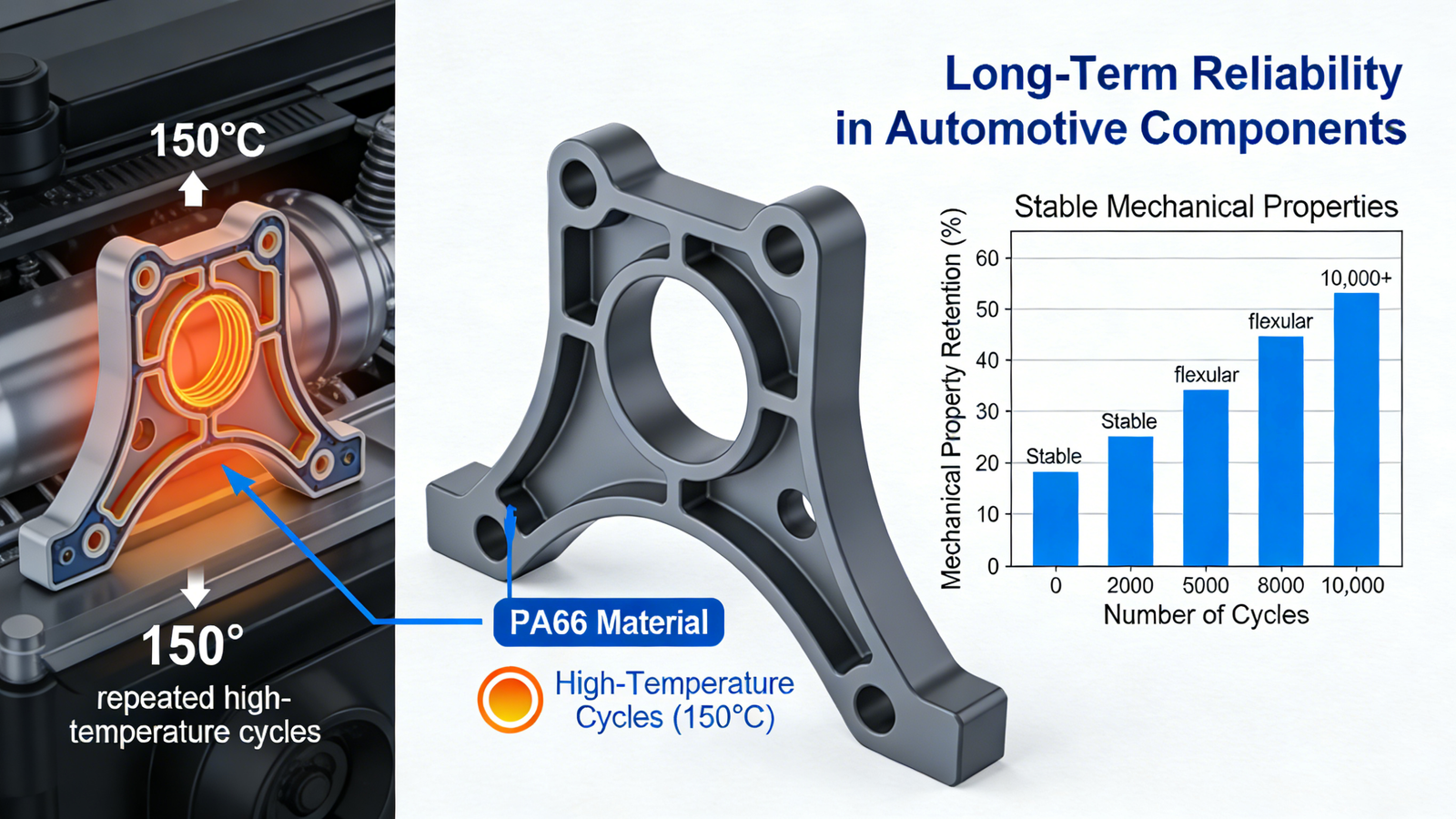

- Material Selection – Works best with high-flow thermoplastics like ABS, Polycarbonate, and Nylon.

- Process Control – Requires precise gas pressure adjustments to avoid uneven distribution.

- Tooling Costs – Higher initial mold investment but significant savings in material and cycle time.

Conclusion

Gas Assist Injection Molding is a highly efficient process that improves plastic part production by reducing material waste, enhancing structural integrity, and shortening cycle times. This technique is particularly valuable in automotive, furniture, and industrial applications where lightweight and durable components are required.

For expert advice on Gas Assist Injection Molding and how it can optimize your production, visit our resource center or contact us. Let’s help you achieve cost-effective, high-quality plastic manufacturing!