Injection molding is a widely used manufacturing process for producing plastic parts and products. It involves the use of a mold, material selection, quality control, and intricate design to create high-quality plastic components. Understanding how injection molding works, the importance of mold design, material selection, and quality control is crucial for achieving successful outcomes in the production process. For detailed time of each stage, please check our injection molding service.

How Injection Molding Works

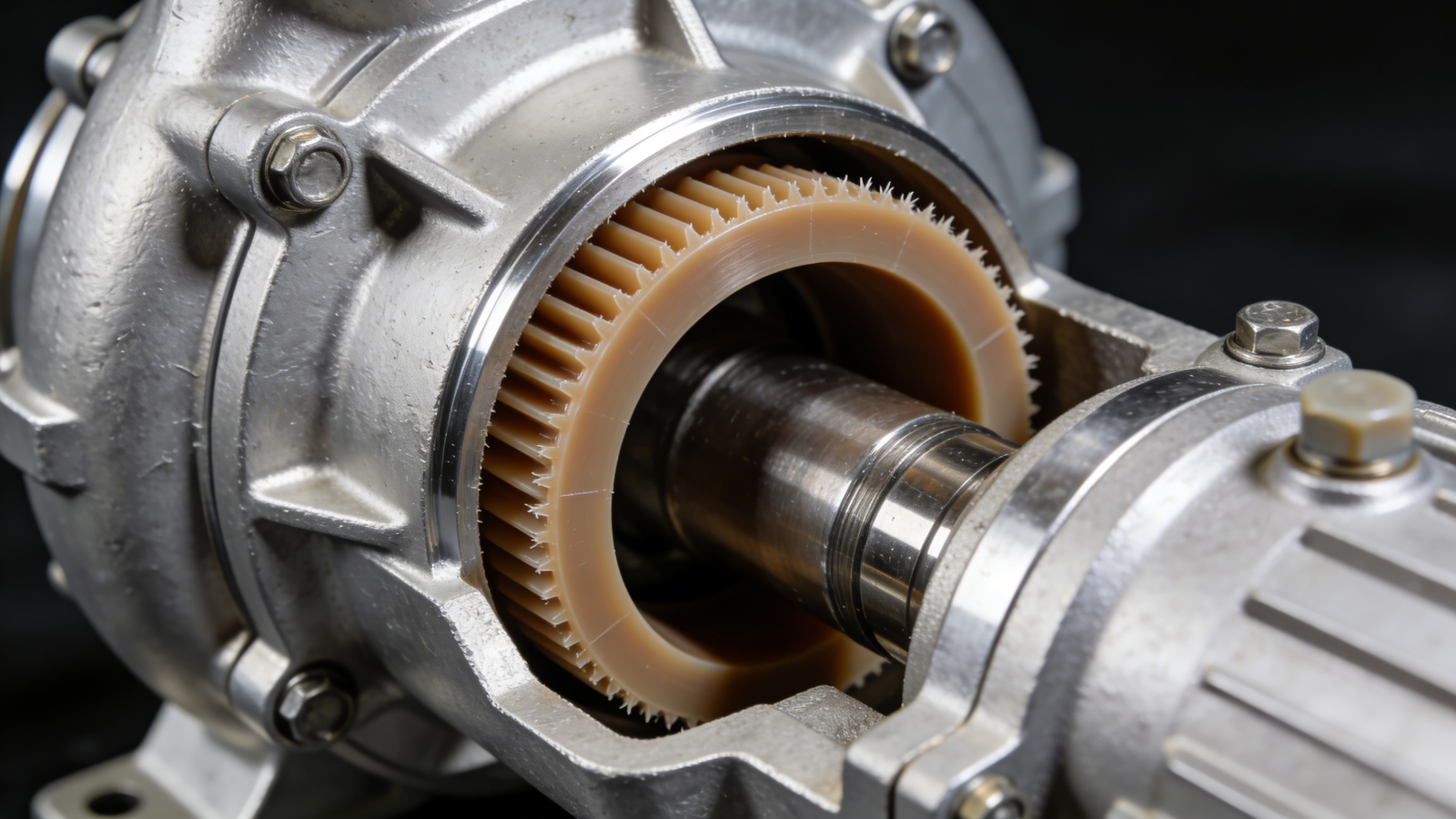

The injection molding process begins with the selection of a suitable material for the desired product. Thermoplastics, thermosetting polymers, and elastomers are commonly used materials in injection molding. Once the material is chosen, it is heated to a molten state and then injected into a mold cavity under high pressure. The material is then allowed to cool and solidify within the mold, taking the shape of the cavity. After solidification, the mold opens, and the newly formed part is ejected, ready for further processing or assembly.

Mold Design

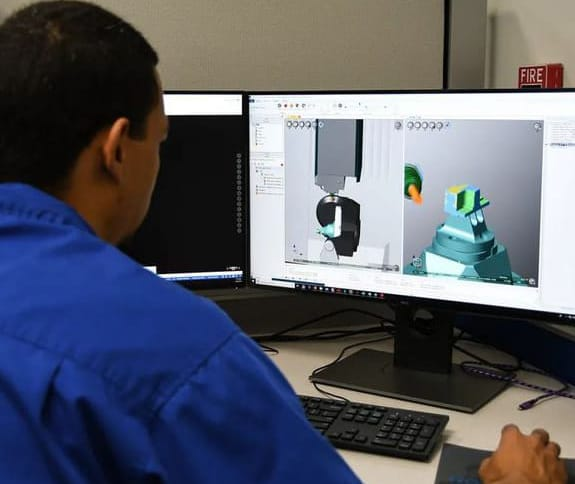

Mold design is a critical aspect of the injection molding process. The design of the mold directly impacts the quality, precision, and efficiency of the final product. Factors such as part geometry, material flow, cooling time, and ejection mechanism need to be carefully considered during the mold design phase. The use of advanced computer-aided design (CAD) software allows for the creation of intricate and precise mold designs, ensuring that the final product meets the required specifications.

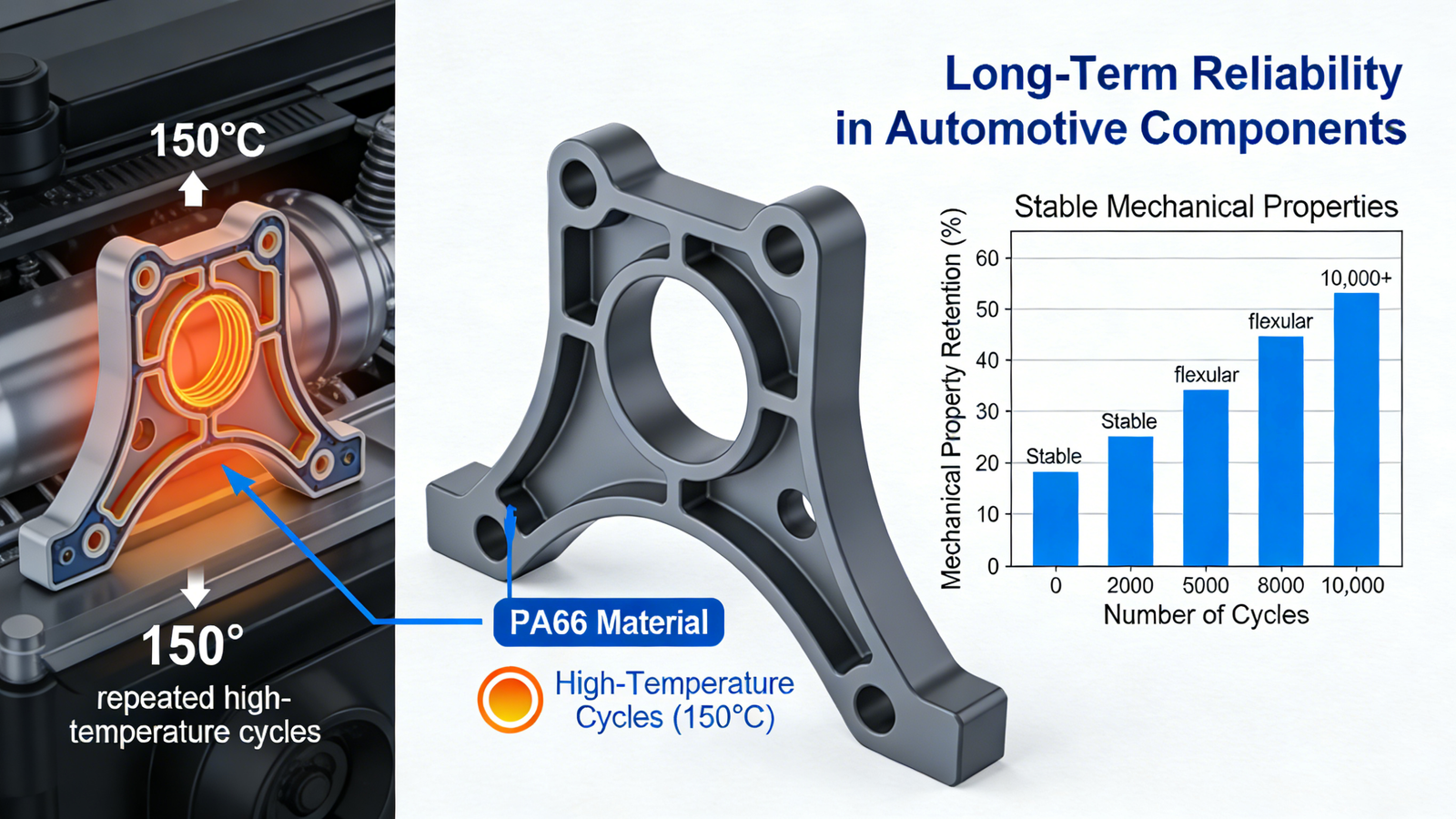

Material Selection

The selection of the right material is essential for the success of the injection molding process. Factors such as mechanical properties, chemical resistance, thermal stability, and cost must be taken into account when choosing a material for a specific application. Additionally, the material should be compatible with the mold design and processing parameters to achieve the desired results. Conducting thorough material testing and analysis is crucial to ensure that the selected material meets the performance and quality standards for the intended application. If you want to knwo more information about our material’s area,please attention Our Advanced Equipment and Exceptional Material Processing Capabilities.

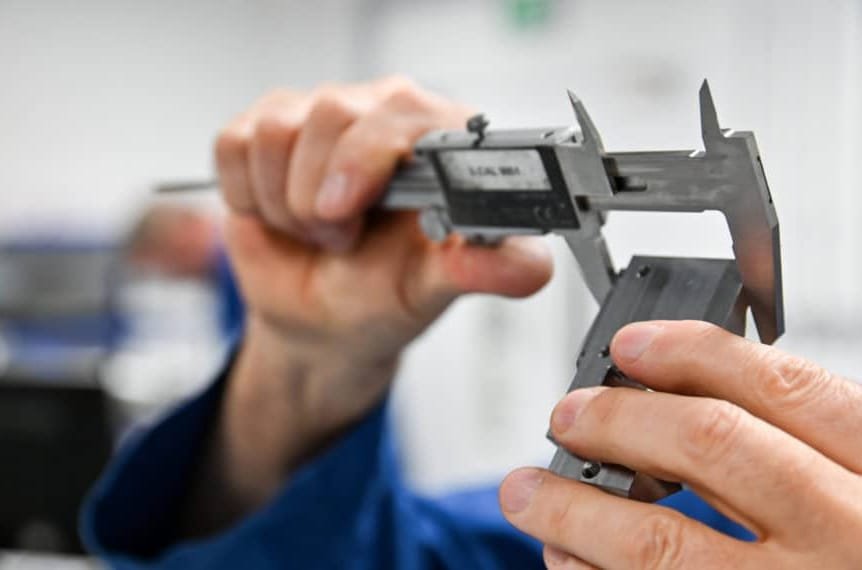

Quality Control

Quality control is an integral part of the injection molding process to ensure that the produced parts meet the required specifications and standards. Various quality control measures, such as dimensional inspection, material testing, and visual inspection, are implemented throughout the production process. Advanced metrology tools, such as coordinate measuring machines (CMM) and optical inspection systems, are used to verify the dimensional accuracy and quality of the molded parts. Additionally, process monitoring and statistical analysis are employed to identify and address any deviations or defects in the production process. As a professional manufacurer, we have own qualtiy testing center, each your customized product will be inspected multiple time.

Conclusion

In conclusion, the injection molding process is a complex and intricate manufacturing technique that requires careful consideration of mold design, material selection, and quality control. By understanding how injection molding works and implementing effective mold design, material selection, and quality control measures, manufacturers can produce high-quality plastic parts and products with precision and consistency. As our technology continues to advance, the injection molding process will continue to evolve, offering new opportunities for innovation and efficiency in plastic manufacturing. If you need please contact us.