Transparent parts are widely used in modern products, which improves the beauty and functionality of products. It is very important to choose the appropriate transparent material and technology.

This paper will discuss the characteristics of common transparent materials and how to choose the appropriate processing technology according to the application scenario.

Which transparent materials perform best in the application scenario?

The performance of transparent materials can indeed vary greatly in different scenarios. When selecting a transparent material, it is necessary to consider the application scenario, performance requirements and cost factors to ensure that the most suitable material is selected.

- Polycarbonate (PC):PC is suitable for applications that require ruggedness due to its high impact and heat resistance.

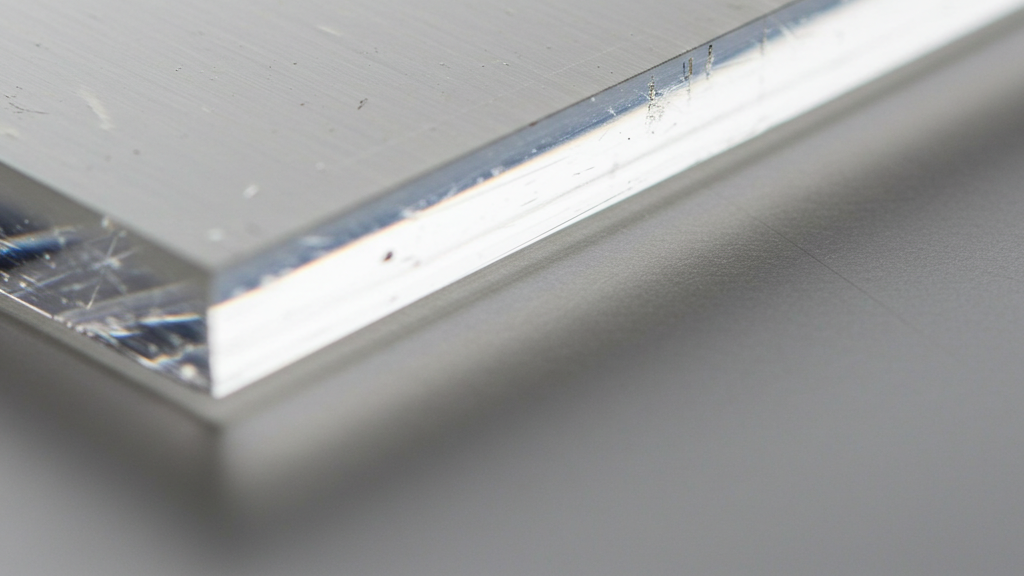

- Polymethyl methacrylate (PMMA, acrylic) :PMMA are suitable for optical and display applications with excellent clarity and ease of processing.

- Glass: Glass, with its extreme transparency and hardness, is suitable for applications that require high stability and chemical resistance.

- Transparent resins (for 3D printing): Clear resins are suitable for customized applications with complex shapes.

What is the impact of the transparent part process on product quality?

The machining process of transparent parts has a crucial impact on product quality, and choosing the right machining process is crucial to ensure the quality of transparent parts.

- Optical performance: The processing process directly affects the optical clarity and light transmission of transparent parts.

- Surface quality: Different processes determine the smoothness and wear resistance of the surface of transparent parts.

- Dimensional accuracy: Machining accuracy ensures that the dimensions of transparent parts meet the design specifications.

- Internal stresses: Improper processing can create internal stresses that affect component strength and optical performance.

- Production cost: The choice of processing technology greatly affects the final production cost of transparent parts.

Transparent part design considerations

When designing transparent parts, it is possible to design transparent parts that meet functional requirements with excellent optical effects and functional requirements by considering the following factors for optimal effect and functionality.

- Material Selection & Optical Properties: The right material to ensure the light transmittance, clarity and light control required for transparent parts.

- Structural design and mechanical properties: reasonable design to ensure uniform wall thickness of transparent parts, avoid stress concentration, and ensure good coordination with other components.

- Machining technology and quality control: Mold design and control of machining parameters are key to ensuring the high quality of transparent parts.

- Application environment and functional requirements: The design of transparent parts should fully consider the weather resistance and chemical resistance of the application environment, and need to be combined with the functionality of the product.

Transparent/translucent process summary

| The name of the process | Applicable Materials | Process characteristics | merit | shortcoming | Application scenarios |

|---|---|---|---|---|---|

| Injection molding | PC、PMMA | Mass production, high precision, good surface finish | High production efficiency, low cost, complex shape | The cost of molds is high, and it is not suitable for small batches | Electronic product shells, car lamp covers |

| 3D printing | Photosensitive resin | Personalized customization, complex structures can be realized, and high flexibility | High degree of design freedom, no tooling, rapid prototyping | The cost is higher, the efficiency is lower, and the materials are limited | Medical models, artwork, custom products |

| Machining | PC, PMMA, glass | High precision, good surface quality, can process hard materials | High precision, wide range of application, a variety of materials | The cost is high, the cycle is long, and the complex shape is difficult | Optical lenses, precision instrument parts |

| Polishing/coating | All transparent materials | Properties such as improving surface finish/increasing surface hardness | Improved optical performance/improved surface performance, longer life | The additional process/cost is high, and the technical requirements are high | Optical components, displays, and transparent components with high requirements |

Factors that enhance the effectiveness and functionality of parts

Improving the effectiveness and functionality of a component requires a combination of several key factors. From material inspection to finished product inspection, every link needs to be strictly controlled. These factors can improve the effectiveness and functionality of the component to meet the needs of a wide range of applications.

1.Material selection: Choose the right materials to ensure that the components have the required optical, mechanical, and environmental adaptability.

2.Processing technology: Through precise processing technology and surface treatment, the high precision and excellent performance of the components are realized.

3.Design considerations: Proper design, including structural, optical, and surface design, is key to improving the effectiveness and functionality of a part.

4.Quality Control: Strict quality control, from material inspection to finished product inspection, to ensure that the parts meet the specifications.

conclusion

To improve the effectiveness and functionality of components, it is necessary to optimize materials, processes, design and quality control. Materials lay the foundation, processes are transformed, design gives soul, and quality control ensures reliability. The combination of these four is the only way to create superior components that meet the growing demands of applications.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!