Introduction

In high-precision assembly applications, PPS low-shrinkage injection parts often serve as dimensional references and long-term stability anchors, directly influencing overall system performance and service life. Precision sourcing has shifted from parameter comparison to system capability evaluation, where a reliable manufacturer must demonstrate integrated strengths in material control, process stability, and delivery coordination.Xiamen Ruicheng’s long-term experience in PPS low-shrinkage injection molding shows that dimensional stability is not the result of a single technique, but of a complete manufacturing system.

When buyers evaluate suppliers from a full lifecycle perspective, PPS low-shrinkage injection parts are no longer standard components, but critical factors determining project success.Identifying a manufacturer that truly understands precision requirements is the starting point for reducing hidden procurement risks.

What Capabilities Define a Reliable PPS Low-Shrinkage Injection Molding Manufacturer?

In precision component sourcing, reliable PPS low-shrinkage injection molding manufacturers distinguish themselves through deep understanding of materials and processes rather than equipment alone. The real differentiator is whether PPS low-shrinkage behavior can be consistently replicated across every injection molding production batch. Based on extensive project experience, Xiamen Ruicheng has found that suppliers with mature quality systems and early-stage engineering involvement maintain superior consistency during mass production, where the integration of PPS material properties and injection molding process control directly determines final part quality.

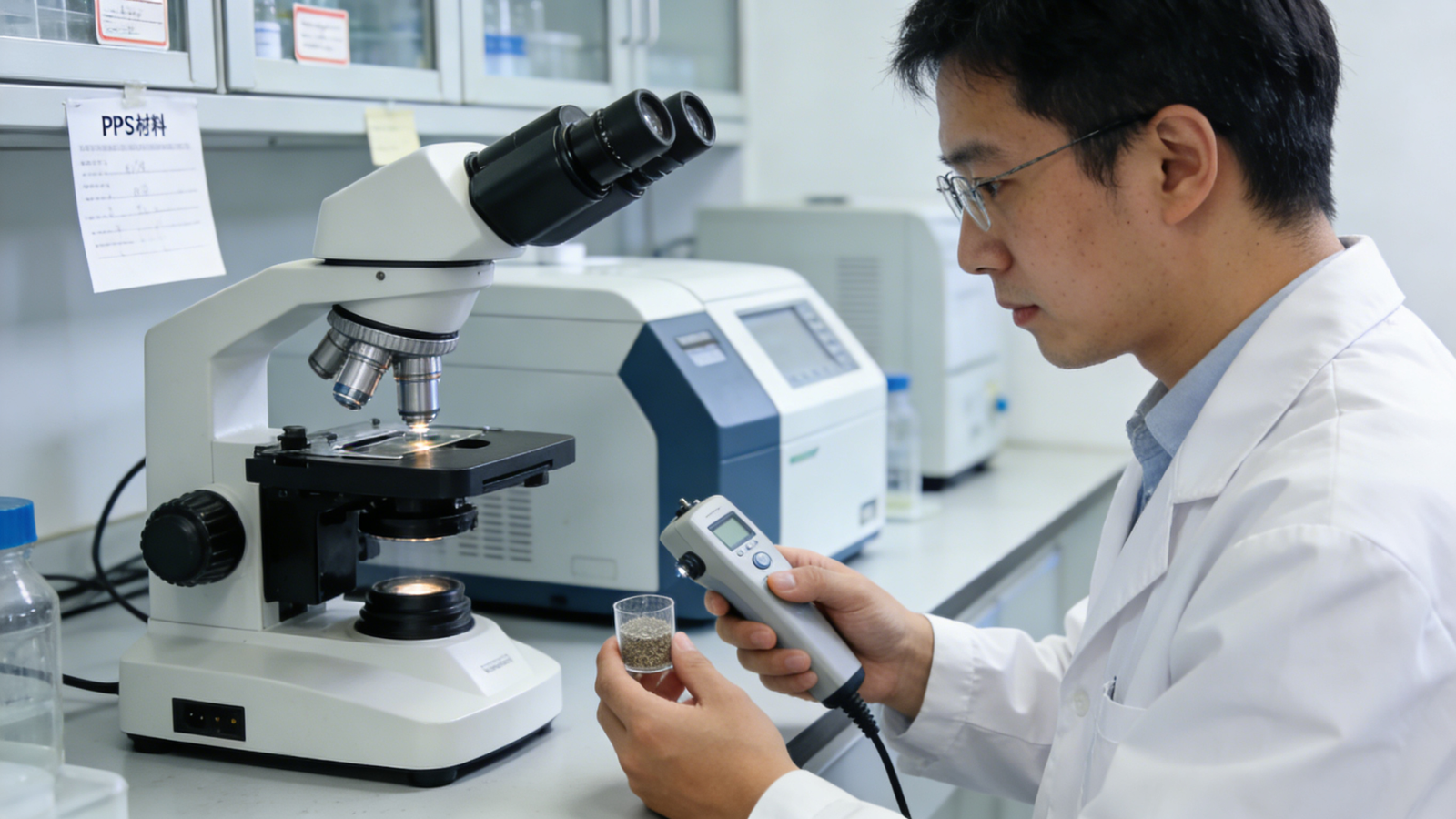

Material expertise: In-depth understanding of PPS crystallization behavior and filler systems enables controlled low-shrinkage molding.

Process accumulation: Established processing windows reduce trial-and-error costs and shorten sampling cycles.

Quality systems: Closed-loop inspection from raw material intake to final shipment prevents dimensional drift during production.

Engineering collaboration: Early design participation provides manufacturability guidance instead of post-production corrections.

🔍 Truly reliable PPS low-shrinkage injection molding suppliers invest most heavily in the details customers rarely see.

How Can Buyers Verify the Stability of PPS Low-Shrinkage Injection Parts?

Verifying PPS low-shrinkage injection part stability requires more than sample approval; it demands evaluation of performance under continuous production. Xiamen Ruicheng emphasizes data-driven validation to demonstrate stability rather than relying on one-time inspection results. Dimensional capability analysis and long-term monitoring make dimensional stability and shrinkage control essential supplier evaluation metrics.

Batch consistency: Assess whether dimensional variation across different production batches remains within control limits.

Process traceability: Confirm the availability of complete process and inspection records supporting quality claims.

Environmental robustness: Evaluate whether dimensions remain stable under temperature or humidity fluctuations.

Continuous improvement: Determine whether suppliers proactively optimize processes based on data insights rather than reactive rework.

📊 Stability verification is a critical step in reducing rework, line stoppages, and hidden lifecycle costs.

Why Is Engineering Support More Valuable Than Unit Price?

In PPS low-shrinkage injection part sourcing, short-term pricing advantages rarely outweigh long-term engineering support. Xiamen Ruicheng prioritizes project success by supporting buyers with engineering collaboration that reduces total ownership cost. Compared with standalone quotations, DFM analysis and injection molding optimization eliminate risks early in the development cycle.

Early involvement: Engineering input before mold development minimizes downstream design changes.

Issue response: Rapid root-cause identification ensures dimensional or assembly issues are resolved efficiently.

Cost optimization: Structural and process improvements reduce manufacturing and maintenance expenses.

Long-term partnership: Stable communication mechanisms enhance supply chain resilience.

🤝 The most reliable PPS injection molding manufacturers act as engineering partners, not just suppliers.

Key Comparison Factors for PPS Low-Shrinkage Injection Molding Manufacturers

| Evaluation Criteria | Conventional Molders | Experience-Based Suppliers | System-Driven Manufacturers | Xiamen Ruicheng |

|---|---|---|---|---|

| Material Understanding | Basic | Advanced | Systematic | Systematic |

| Process Stability | Variable | Relatively Stable | Highly Stable | Highly Stable |

| Engineering Support | Reactive | Semi-Proactive | Proactive | Proactive |

| Quality Traceability | Limited | Partial | Complete | Complete |

| Long-Term Collaboration | Weak | Moderate | Strong | Strong |

If you aim to avoid repeated trial-and-error and secure sustainable engineering support when sourcing PPS low-shrinkage injection parts, contact us

Reducing Procurement Risk from Sampling to Mass Production

Procurement risks in precision components rarely emerge during sampling but escalate during production scale-up. Xiamen Ruicheng mitigates these risks through phased validation and transparent collaboration, helping customers build confidence throughout PPS low-shrinkage injection molding projects. This approach ensures continuity from pilot production to stable mass manufacturing rather than relying on single-stage commitments.

1.Phased validation: Small-batch trials confirm process stability before scale-up.

2.Data transparency: Key quality and process metrics are shared with customers.

3.Risk anticipation: Potential dimensional and delivery risks are identified early.

4.Collaborative optimization: Design and process refinements are completed prior to full production.

FAQ Module

Question 1: What are the core advantages of your PPS low-shrinkage injection parts?

Answer: Xiamen Ruicheng combines mature PPS material systems with standardized process control, defining clear shrinkage ranges and dimensional capability limits. Full-process inspection and data traceability ensure consistent quality aligned with buyers’ stability requirements.

Question 2: What information is required to obtain a quotation efficiently?

Answer: Buyers should provide 3D/2D drawings, annual demand forecasts, and assembly requirements. Once submitted through the designated communication channel, our engineering team delivers a process-evaluated quotation with risk analysis within the agreed timeframe.

Question 3: How do MOQ and lead time vary by order volume?

Answer: Different MOQ and lead-time strategies are applied for pilot and mass production stages. Xiamen Ruicheng balances flexible scheduling and capacity planning to support both low-volume validation and high-volume supply stability.

Question 4: How are quality or delivery issues handled?

Answer: Based on predefined quality criteria, issues trigger a rapid analysis process. Responsibility is clarified promptly, followed by corrective actions, replacements, or process improvements to protect project timelines.

Question 5: Do you support customized PPS low-shrinkage injection solutions?

Answer: Yes. Xiamen Ruicheng provides customized material formulations, structural adjustments, and process optimization based on specific application and assembly requirements, with clearly defined lead times and cost implications.

Conclusion

Sourcing PPS low-shrinkage injection molding manufacturers for precision components is fundamentally an evaluation of system capability and long-term collaboration value. Xiamen Ruicheng delivers verifiable, sustainable low-shrinkage injection solutions through engineering-driven processes and closed-loop quality systems. When procurement decisions shift from short-term pricing to lifecycle stability, the true value of reliable partnerships becomes clear.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!