The process begins with a detailed design. Engineers use computer-aided design (CAD) software to create a digital model of the product. These models help visualize the final product, identify potential design flaws, and make necessary adjustments before moving into production.

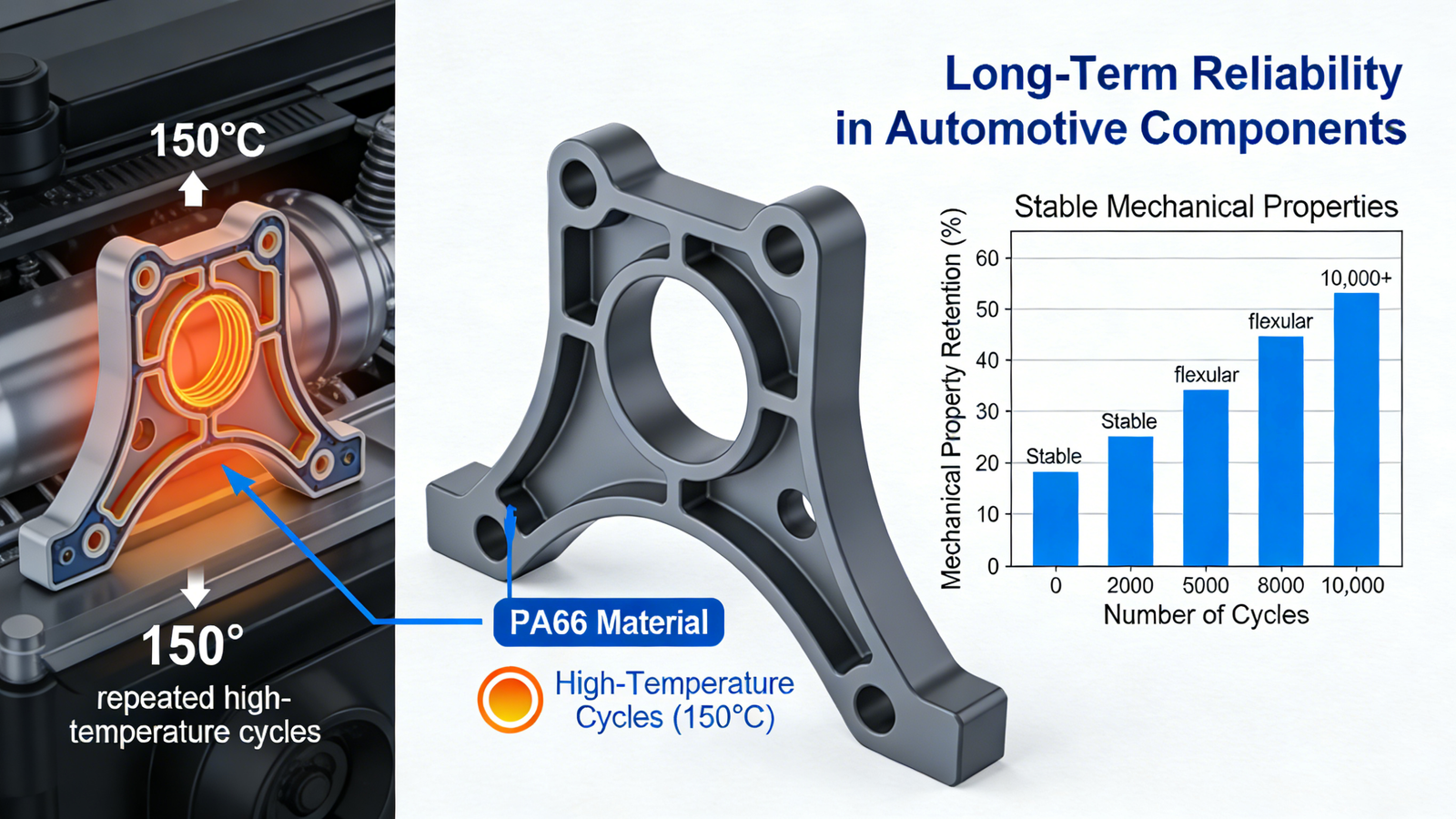

Step 2: Material Selection

Choosing the right plastic material is crucial for the functionality and durability of the final product. Common materials include ABS, PVC, PP, PE, Nylon, and PET. Each material has specific properties such as strength, flexibility, heat resistance, and chemical resistance.

Step 3: Mold Design and Fabrication

The mold is a critical component in plastic manufacturing. It determines the shape and surface quality of the final product. Mold design involves creating a precise model of the mold, which is then fabricated using high-precision machinery.

Tools and Equipment Used: CNC machines (for mold fabrication), Electrical Discharge Machines (EDM, for intricate mold details)

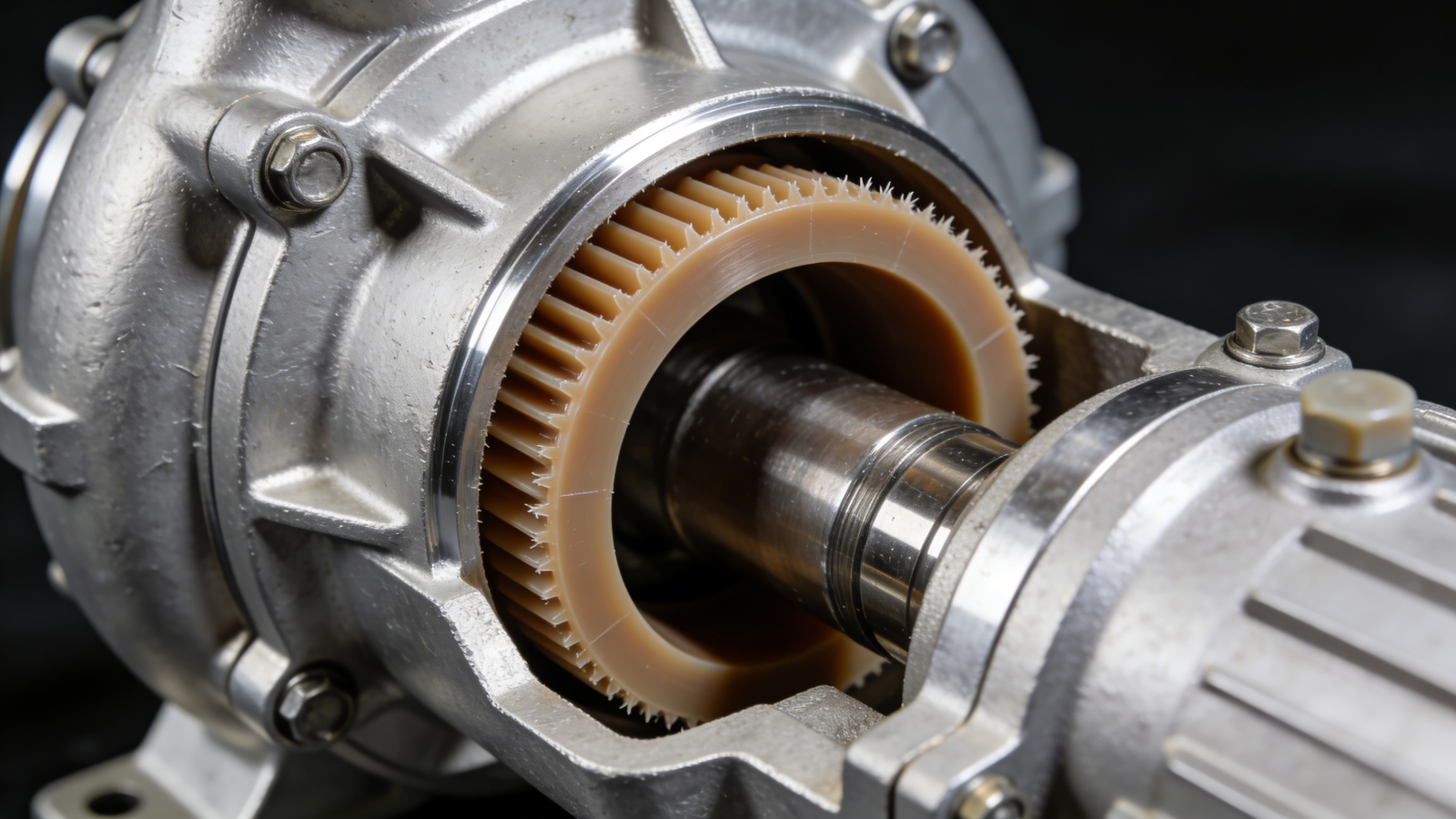

Step 4: Injection Molding Process

Injection molding is the most common method for mass-producing plastic products. This process involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape.

Step 5: Secondary Processes

After molding, plastic parts may undergo several secondary processes to enhance their properties and finish. These processes include trimming, painting, printing, and assembly.

Step 6: Quality Control

Ensuring the quality of plastic products is vital. Quality control involves inspecting parts for defects, measuring dimensions, and testing their performance under various conditions.

Step 7: Packaging

After passing quality control, products are packaged and prepared for shipping. Proper packaging is essential to protect products during transit and storage.

Conclusion

Manufacturing plastic products involves a series of detailed steps from design to final production. By selecting the right materials, precisely designing molds, optimizing the injection molding process, and conducting rigorous quality control, high-quality plastic products can be produced. Following these steps and using specialized equipment, manufacturers can efficiently produce products that meet customer needs.