PPS injection molding materials, with their excellent thermal stability, chemical resistance, and good mechanical properties, are widely used in industries such as automotive, electrical, and electronics. Providing customized PPS injection molding solutions for our clients helps enhance product performance and quality. With years of injection molding experience, we are committed to offering the most suitable technical support and solution designs for each client.

What are the main advantages of PPS injection molding?

PPS injection molded parts are commonly used in industries requiring high heat resistance due to their thermal stability and good mechanical properties. PPS materials have excellent chemical resistance, making them suitable for use in harsh environments. Here’s a summary of the advantages of PPS injection molding:

- High-Temperature Performance: PPS injection molded parts can be used in high-temperature environments for extended periods, widely applied in automotive engine components.

- Chemical Resistance: Can withstand acidic and alkaline environments, commonly used in the chemical industry.

- Mechanical Strength: PPS materials offer outstanding hardness and compressive strength, making them suitable for load-bearing parts.

- High Precision: PPS Injection Molding Precision Requirements achieves ultra-high precision products through high-precision molds and processes.

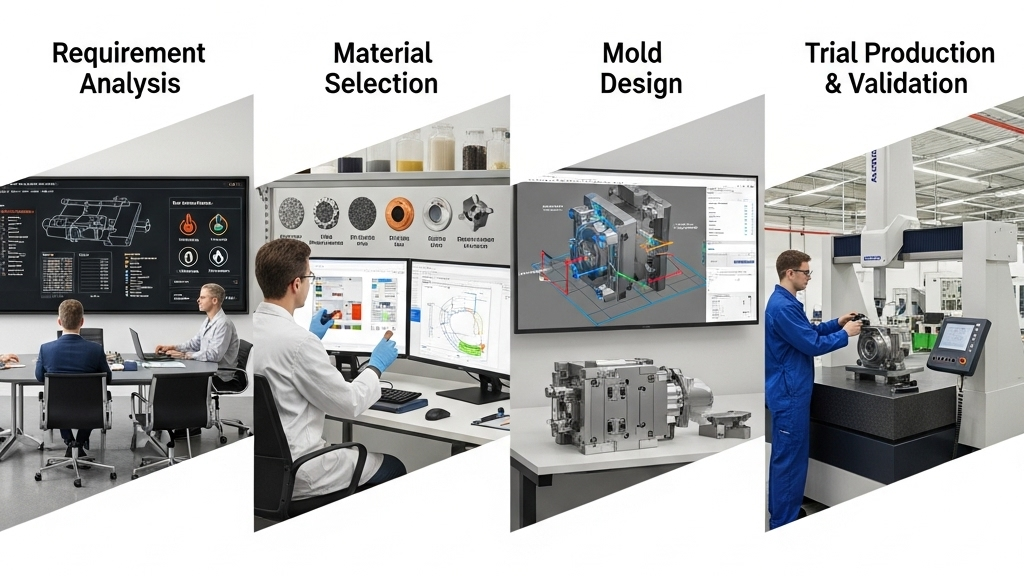

What is the development process for PPS injection molding solutions?

The development of PPS injection molding solutions requires collaboration across multiple stages, from material selection to mold design. We customize the production process based on the specific needs of our clients. Here are the key steps in the development process:

- Requirement Analysis: PPS Injection Molding Design Requirements through close communication with clients to define the product's functional needs.

- Material Selection: Choosing the appropriate PPS material based on performance requirements to ensure the final product meets usage standards.

- Mold Design: Designing molds that meet production needs and optimizing production efficiency and quality.

- Trial Production and Validation: Conducting small-scale trial production to ensure stable product quality and meet client expectations.

How do we ensure the quality of PPS injection molding solutions?

Ensuring the quality of PPS injection molding solutions is our top priority. Through strict quality control processes, we ensure the stability and reliability of each injection molded product. Here are some key steps in quality assurance:

- Strict Raw Material Testing: Every batch of raw materials is rigorously tested to ensure compliance with standards.

- High-Standard Mold Control: Mold Control Process ensures precision in product design and manufacturing through sophisticated molds and processes.

- Quality Tracking: Real-time monitoring and quality tracking during production to minimize defect rates.

- Final Acceptance: Each batch of products undergoes final quality inspection to ensure they meet client requirements.

Comparison of PPS Injection Molding Solutions

| Item | High-Temperature Stability | Chemical Resistance | Mechanical Strength | Precision | Applications |

|---|---|---|---|---|---|

| Advantages | High | High | High | High | Automotive, Electronics |

| Disadvantages | Brittle | Expensive | Difficult to Process | Medium | Some Chemicals |

| Application Industries | Automotive | Chemical Industry | Electronics | Precision | Medical, Electronics |

| Technical Difficulty | Medium | High | High | High | Industrial, Energy |

Expansion

The application of PPS injection molding is continually expanding, especially in the automotive and electronics fields. With technological advancements, PPS injection molding materials will be more widely used in future high-precision, high-strength components. In our customized services, clients can receive more targeted solutions, enhancing the competitiveness of their final products.

1.Automotive Industry: PPS injection molding materials are used in automotive engine components, transmission systems, and electronic modules.

2.Electronics Industry: High-performance electronic parts such as battery housings, displays, etc.

3.Medical Industry: High-precision parts for medical devices, especially products requiring corrosion and heat resistance.

4.Home Appliance Industry: Providing heat-resistant and chemical-resistant components for home appliances, extending product lifespan.

Conclusion

With our customized PPS injection molding solutions, clients can enjoy efficient, precise, and high-performance product design services. Our technical team provides full support based on each client's needs, ensuring that every product perfectly meets market requirements.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!