Introduction

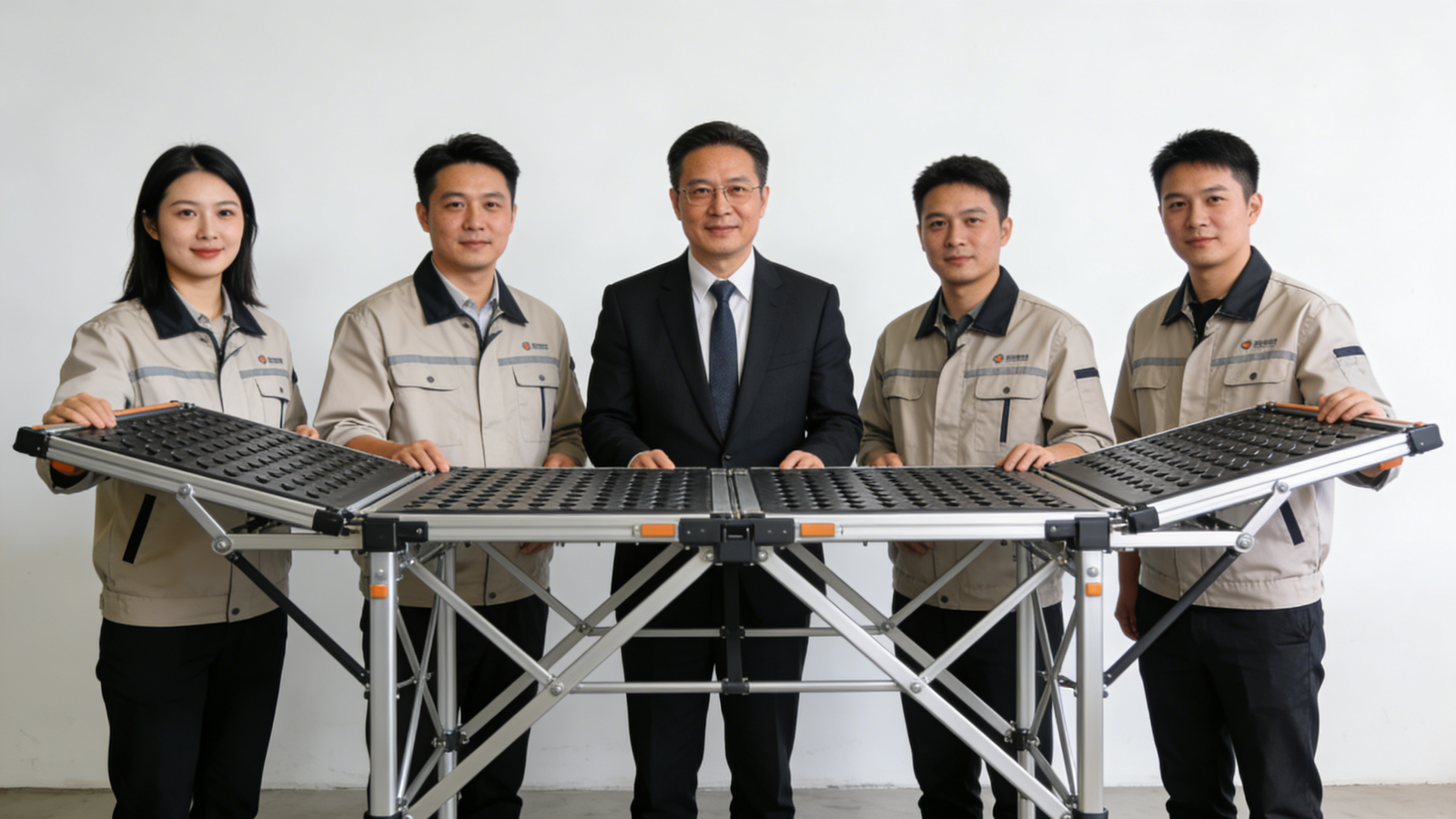

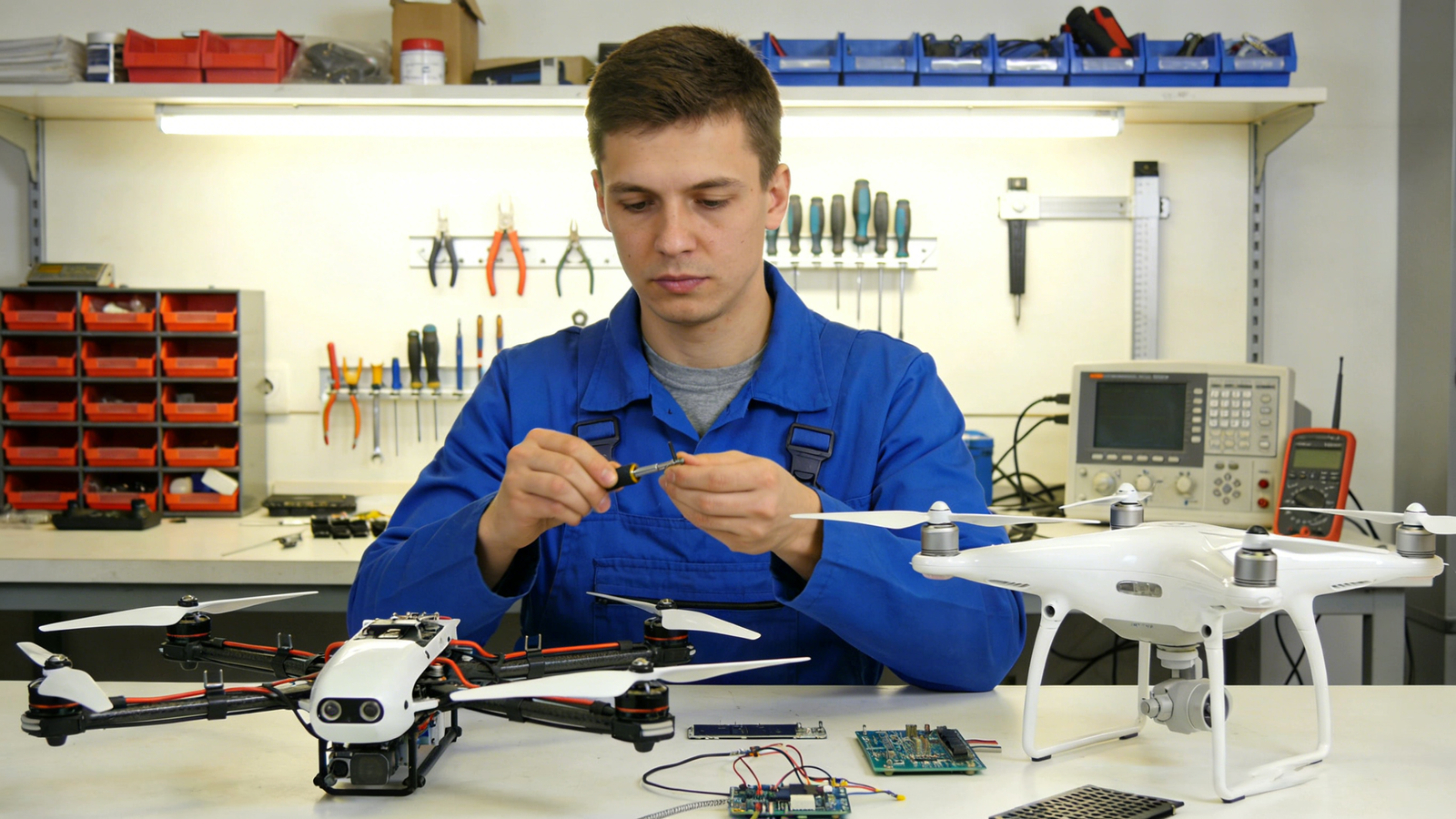

Drones operate under high-speed rotation, complex loads, and constantly changing environments, which places far higher demands on structural materials than conventional industrial products. Lightweight PEEK injection molded parts have therefore become a key solution for high-end drone applications. Based on long-term experience in drone and aerospace structural projects, Xiamen Ruicheng has found that procurement decisions focused only on material grades often expose systemic risks during mass production.What truly defines a drone’s performance ceiling is not whether PEEK is used, but whether a complete, application-driven core metric evaluation system is established.

Under the trend of lightweight design, injection molded parts are no longer simple structural components; they directly affect flight stability, energy efficiency, and long-term reliability. Xiamen Ruicheng consistently supports customers with quantifiable, verifiable, and reproducible metrics to close the decision loop from selection to mass production.

How Can Lightweight PEEK Injection Molded Parts Balance Strength and Weight in Drones?

Lightweight PEEK injection molded parts for drones must be evaluated systematically around weight, structural strength, and dynamic loads from the earliest design stage, rather than pursuing weight reduction alone. In practical projects, Xiamen Ruicheng combines analysis of PEEK material properties with lightweight structural design to help customers reduce redundant mass while maintaining flight load requirements. Weight optimization does not mean minimizing wall thickness, but redistributing material based on stress paths.

Strength margin: Retaining sufficient safety factors in critical load-bearing areas to avoid fatigue accumulation during flight.

Weight allocation: Using ribs and hollow structures to place mass where structural efficiency is highest.

Dynamic loads: Accounting for transient impacts during takeoff, landing, and vibration rather than static strength alone.

Molding consistency: A stable molding window ensures consistent weight and strength distribution across batches.

🚀 True lightweight design is about putting the right weight in the right place.

Why Does Dimensional Stability of PEEK Injection Parts Determine Flight Precision?

In drone applications, PEEK injection molded parts often serve as mounting references and motion support structures, making dimensional stability critical to flight control accuracy and long-term reliability. Xiamen Ruicheng controls injection molding shrinkage and thermal expansion coefficients to ensure structural consistency under temperature fluctuations and vibration. Dimensional drift rarely causes instant failure but gradually accumulates into system-level errors.

Mold precision: High-precision tooling is the foundation of dimensional stability, not a post-process correction.

Process window: Stable temperature, pressure, and cooling profiles minimize residual internal stress.

Material batches: Unified raw material sourcing avoids crystallization behavior differences between batches.

Assembly validation: Dimensional regression testing is conducted under real assembly conditions.

🎯 Stable dimensions are the invisible safeguard of long-term flight accuracy.

How Do Lightweight PEEK Injection Molded Parts Withstand Heat and Vibration?

During operation, drones are exposed to motor heat sources, airflow variations, and continuous vibration, imposing dual challenges of thermal stability and fatigue resistance on PEEK injection molded parts. Xiamen Ruicheng prioritizes matching PEEK thermal performance with vibration fatigue testing under real application conditions. Only performance verified in actual operating environments has engineering value.

Heat deformation control: Ensuring structural integrity under continuous operating temperatures.

Vibration durability: Simulating long-term flight vibration through fatigue testing.

Material modification: Selecting reinforced or wear-resistant PEEK grades based on operating conditions.

Service life evaluation: Assessing durability in flight hours rather than single test outcomes.

🔥 Environmental adaptability determines whether lightweight design is truly usable.

Reference Comparison Table of Core Metrics for Lightweight PEEK Injection Molded Drone Parts

| Metric Dimension | Key Focus | Common Risk | Xiamen Ruicheng Control Method |

|---|---|---|---|

| Strength-to-weight ratio | Structural efficiency | Over-lightweighting | Stress simulation validation |

| Dimensional stability | Assembly accuracy | Thermal drift | Locked process window |

| Thermal performance | Continuous heat resistance | Deformation failure | Real-condition testing |

| Fatigue life | Vibration environment | Hidden microcracks | Long-cycle endurance tests |

Want to understand how these metrics fit your specific project? Feel free to contact us

A Systematic Path from Metric Evaluation to Mass Production

The real value of lightweight PEEK injection molded parts for drones only emerges at the mass production stage. By front-loading core metrics into design and validation phases, Xiamen Ruicheng helps customers avoid the common issue of “samples pass, mass production fails.” A systematic evaluation path reduces overall risk more effectively than isolated parameters.

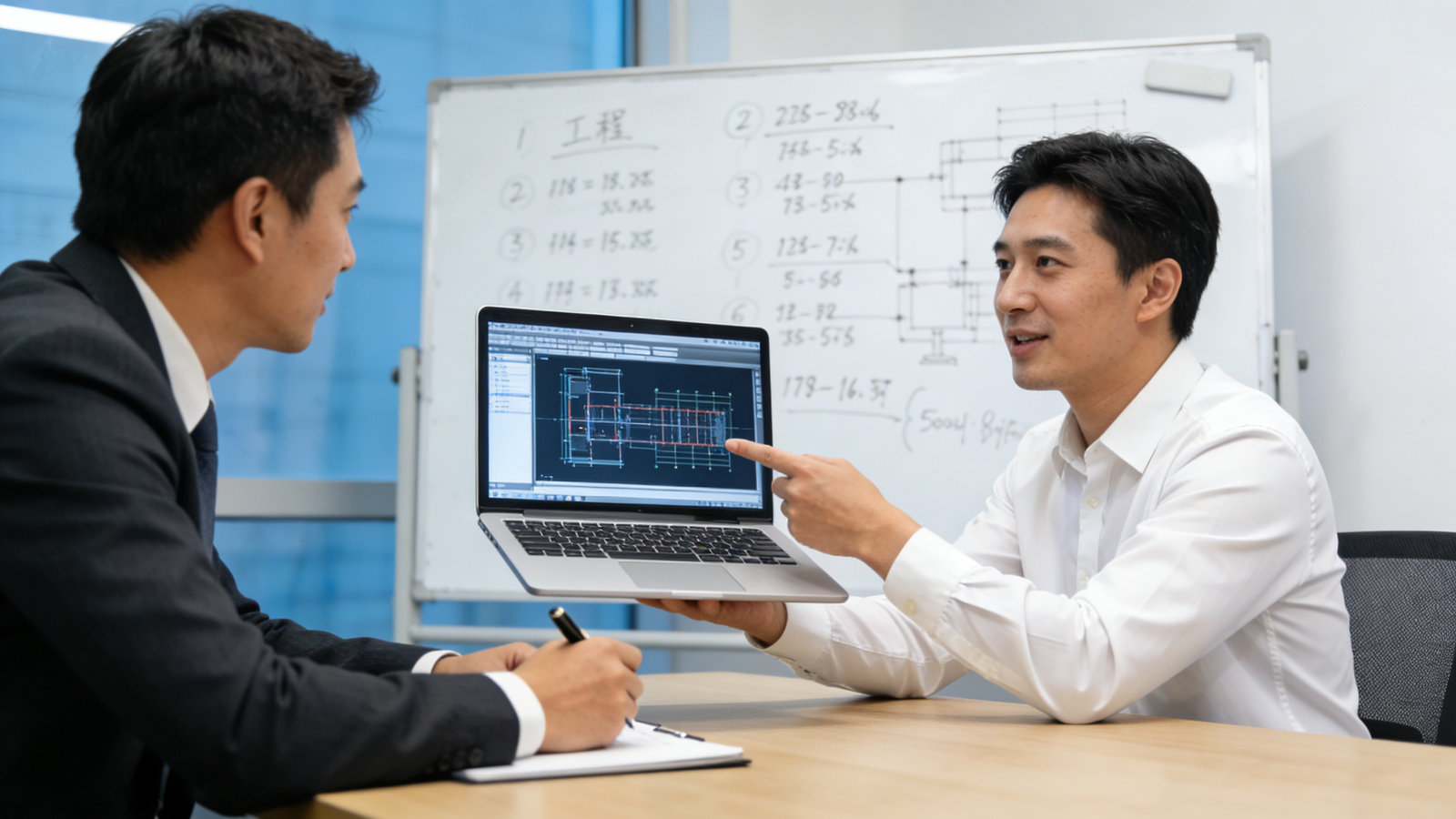

1.Metric definition: Translating application scenarios into quantifiable indicators.

2.Process validation: Verifying mass-production stability during trial molding.

3.Risk prediction: Identifying potential failure modes in advance.

4.Continuous optimization: Maintaining data traceability throughout production.

FAQ

Question 1: What are the core advantages of your lightweight PEEK injection molded parts for drones?

Answer: Xiamen Ruicheng defines key metrics such as weight, strength, dimensional stability, and fatigue life based on real flight conditions, supported by both simulation and physical testing, enabling buyers to reduce selection risk.

Question 2: What information is required to start procurement and quotation?

Answer: We recommend providing structural drawings, target weight range, operating temperature, and expected flight life; our engineering team will complete an initial process evaluation and feedback within 12 hours.

Question 3: How are delivery cycles handled for different order volumes?

Answer: Small-batch pilot runs are supported for validation, while standard mass production lead time is 7–10 days; larger projects benefit from capacity pre-planning for stable delivery.

Question 4: How are quality or assembly issues handled after delivery?

Answer: Xiamen Ruicheng provides clear issue identification standards; once responsibility is confirmed, rework or replacement is initiated within 48 hours, with quality assurance on core structural parts.

Question 5: Do you support customization and structural optimization?

Answer: Yes, we offer application-specific structural and process optimization; customers need to provide detailed operating conditions, and customized solutions are typically delivered within three working days.

Conclusion

Selecting lightweight PEEK injection molded parts for drones is fundamentally a system-level engineering decision rather than a simple comparison of material parameters. Xiamen Ruicheng helps customers control technical risks early through a core metric framework. When every metric is aligned with real operating conditions, lightweight design truly translates into flight advantage.

This approach not only enhances product reliability but also brings greater certainty and long-term value to procurement decisions.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!