Introduction

PMMA precision injection parts play a critical role in optical lens applications, where imaging quality, visual consistency, and long-term reliability must be achieved simultaneously. For optical-grade products, even microscopic defects can be magnified in real-world use, directly determining whether a component is commercially viable.

In Xiamen Ruicheng’s practical manufacturing experience, optical lens failures are rarely caused by insufficient parameters, but by overlooked decisions made at the early stage.

As PMMA injection molding transitions from product display to decision companionship, the real value lies in helping customers identify risks, control variables, and establish a repeatable quality pathway. Only when optical requirements are embedded into design and process decisions upfront can PMMA precision injection parts consistently meet optical lens standards.

Why Do PMMA Precision Injection Parts Often Fail in Optical Lens Applications?

Failures of PMMA precision injection parts in optical lens applications usually originate from mismatches between material selection, mold design, and processing windows. These issues may not be obvious during initial sampling but tend to surface during mass production. Optical lenses impose far higher requirements on transparency, internal stress, and surface integrity than standard transparent injection parts. At Xiamen Ruicheng, we focus on analyzing the relationship between PMMA material properties and optical injection molding defects to prevent generic molding experience from being misapplied to optical scenarios. Identifying these failure drivers at the decision stage significantly reduces rework and performance inconsistency.

Material suitability: Optical-grade PMMA demands stricter control of molecular weight distribution and impurity content.

Mold structure: Optical lens parts are extremely sensitive to runner balance and venting design.

Process window: Molding temperature and packing profiles directly affect internal stress distribution.

Production consistency: Batch stability determines whether optical performance can be reliably replicated.

😊 Most failures originate from early decisions, not from the shop floor.

How Can Injection Molding Process Control Ensure Optical Transparency and Low Stress in PMMA?

Achieving optical-grade transparency and low internal stress in PMMA precision injection parts requires tight control of thermal, pressure, and flow conditions throughout the entire molding process. At Xiamen Ruicheng, we prioritize process stability over pushing individual parameters to extremes. By integrating injection molding process control with optical-grade plastic molding expertise, we ensure that optical performance remains consistent under real production conditions. The key is not how high the parameters are, but whether they are repeatable and verifiable.

Temperature management: Coordinated mold and melt temperature control reduces birefringence risk.

Filling strategy: Stable flow fronts help minimize stress concentration.

Packing logic: Optimized packing profiles enhance surface density and clarity.

Cooling rhythm: Balanced cooling prevents localized stress freezing.

🔍 Optical performance is built through process control, not post-production fixes.

How Should Buyers Evaluate the Real Capabilities of a PMMA Precision Injection Molding Manufacturer?

Selecting a PMMA precision injection molding supplier for optical lenses is not about comparing equipment lists or prices alone, but about assessing long-term partnership capability. Xiamen Ruicheng approaches every project from the customer’s full decision-making chain, not from a single processing step. By reviewing a supplier’s quality management system and precision injection molding capability, buyers can better judge whether the manufacturer truly understands optical application risks. A reliable partner anticipates problems before they occur, rather than explaining them afterward.

Early involvement: Participation in manufacturability analysis at the design stage.

Process transparency: Clear and structured validation pathways.

Inspection capability: Availability of optical-grade inspection methods.

Collaboration mindset: Willingness to optimize jointly rather than execute passively.

🤝 Choosing a supplier is ultimately choosing a lower-risk decision path.

Key Decision Factors for PMMA Optical Lens Precision Injection Molding

| Decision Dimension | Standard Transparent Molding | Conventional Precision Molding | Optical-Grade PMMA Molding | Xiamen Ruicheng Solution |

|---|---|---|---|---|

| Material Control | Basic grade | Batch-controlled | Optical-grade dedicated | Front-end material evaluation |

| Process Stability | Experience-driven | Parameter-based | Window-managed | Data-validated control |

| Internal Stress | Passive acceptance | Local optimization | Systematic control | End-to-end coordination |

| Project Support | Delivery-oriented | Process-oriented | Application-oriented | Decision companionship |

Which path best fits your optical lens project? Feel free to contact us for direct discussion.

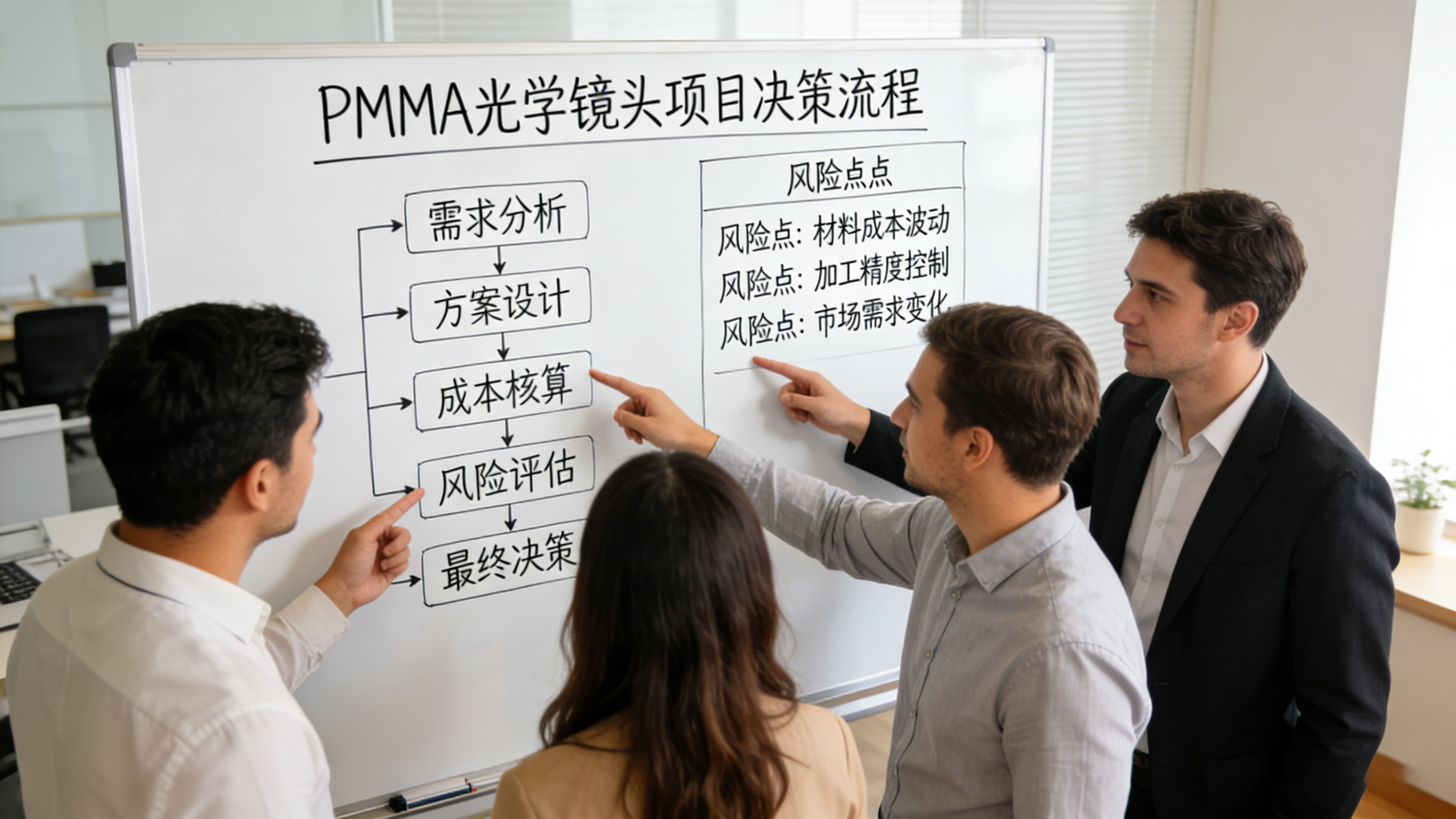

From Parameter Display to Decision Companionship

At Xiamen Ruicheng, PMMA precision injection molding is no longer about proving what can be manufactured, but about determining what should be manufactured. The success of optical lens projects is often decided by early judgment rather than late-stage correction. Through structured evaluation, we help customers define technical boundaries and commercial risks clearly, making every investment more predictable.

1.Requirement clarification: Identifying true optical performance targets.

2.Risk front-loading: Exposing potential failure points before mass production.

3.Solution co-development: Joint optimization of material and process pathways.

4.Continuous validation: Ensuring stable output throughout the product lifecycle.

Frequently Asked Questions (FAQ)

Question 1: What is the quality baseline for your PMMA precision injection parts?

Answer: We use optical-grade application requirements as our baseline, ensuring transparency consistency and internal stress control through validated processes and inspection methods aligned with customer usage needs.

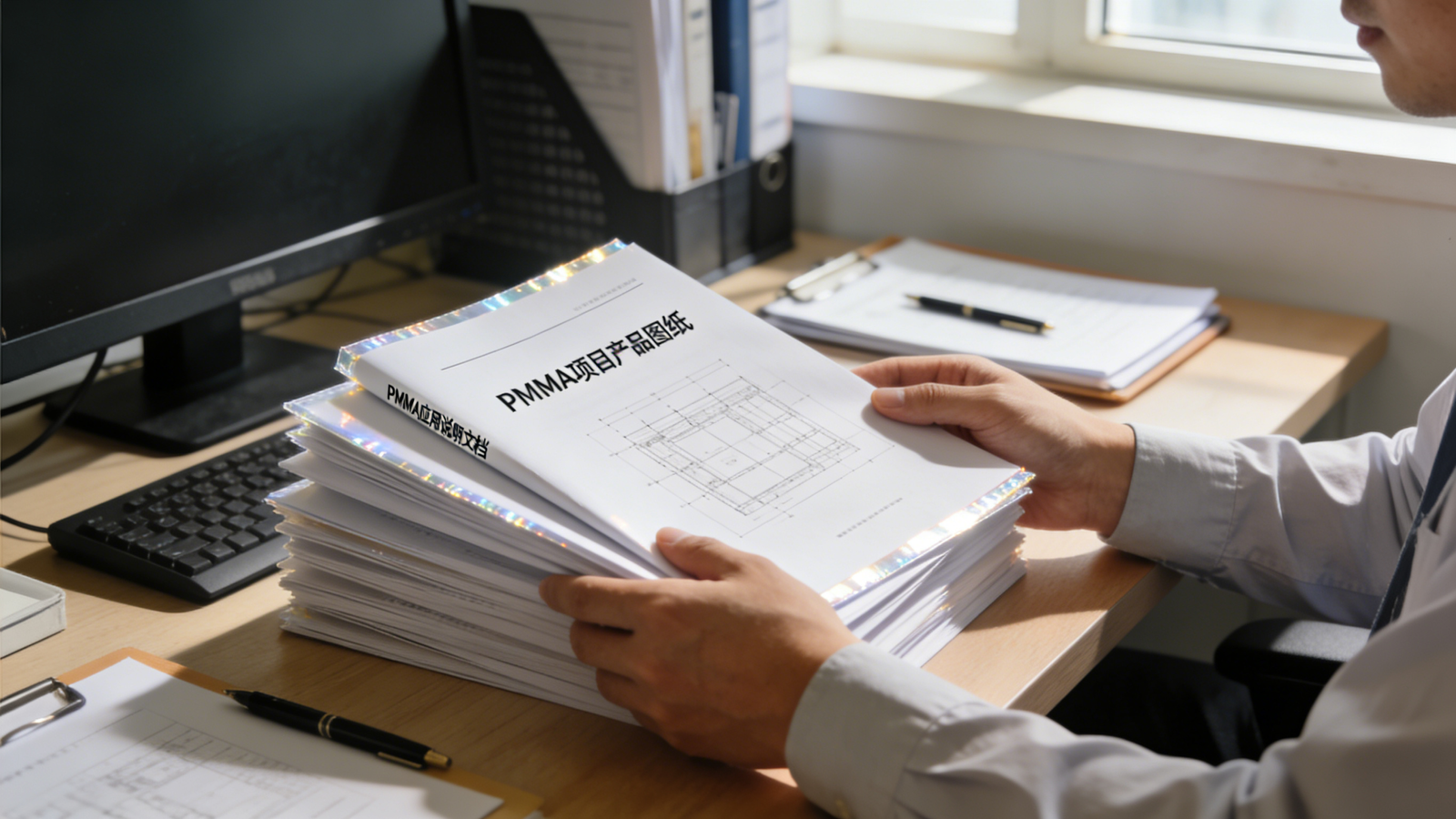

Question 2: What information is required to start a PMMA optical lens project?

Answer: Typically, we require product drawings, application descriptions, and expected volumes. Our engineering team quickly evaluates feasibility and highlights potential risks after review.

Question 3: How do delivery and support differ across order volumes?

Answer: Small-batch phases focus on validation and optimization, while mass production emphasizes stability and efficiency, with dedicated capacity and project management aligned to volume levels.

Question 4: How are optical performance issues handled after delivery?

Answer: We apply a clear issue-definition and improvement process, using data traceability and process adjustments to identify root causes and implement corrective actions efficiently.

Question 5: Do you support customized solutions for special optical requirements?

Answer: Yes, we provide tailored solutions based on specific application conditions, clearly defining feasibility, timelines, and cost implications upfront.

Conclusion

For PMMA precision injection parts to truly meet optical lens requirements, success depends not on parameter accumulation, but on systematic decision-making and process control. Xiamen Ruicheng supports customers by shifting from product display to decision companionship, reducing uncertainty in complex choices. When manufacturing logic aligns with application needs from the beginning, optical-grade PMMA injection parts can deliver stable and sustainable commercial value.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your man