Whether to use concave or convex characters impacts not only mold design paths but also affects injection rhythm and surface finishing. In mass production, the text design often becomes a hidden cost lever.

Concave designs convey embedded security, while convex designs emphasize a bold brand presence. The difference ultimately affects tool wear, cycle time, and yield rate.

How does concave text design influence mold manufacturing cost?

Concave text requires material removal via machining or EDM to form the cavity, with polishing focused on local areas. This process typically shortens total mold fabrication time and reduces tool replacement frequency.

- Simplified machining: One-pass EDM can cut mold hours by 15%.

- Reduced wear: Lower tool load extends lifespan by ~10%.

- Easier polishing: Localized grooves are simpler to finish.

- Material savings: Lower cutting volume means better material utilization.

What impact does convex lettering have on injection molding cycle time?

Convex letters form raised cores in the mold, causing molten plastic to flow around and cool slower at those areas. This typically increases cycle time by 3–5%.

- Cooling delays: Thicker sections dissipate heat slowly.

- Higher holding pressure: Needed to avoid sink marks.

- Surface rework: Raised areas prone to scratches.

- Gloss control: Top surfaces may need secondary coating.

How to evaluate total ownership cost between concave and convex text in mass production?

In high-volume projects, depreciation, maintenance, and downtime risks are evaluated. Overall, concave designs show ~7% lower per-part cost over five years.

- Depreciation savings: Less mold wear = longer life.

- Faster changeover: Smaller mold volume allows quicker switches.

- Consistent quality: Concave text reduces flash and increases yield.

- Brand premium: Convex designs justify higher retail pricing.

Cost-Efficiency Comparison Table

| Key Factor | Concave Design | Convex Design | Business Impact | Notes |

|---|---|---|---|---|

| Mold Time | Low | High | Machining time difference | Standard steel |

| Injection Cycle | Slightly short | Slightly long | Varies by productivity | Same equipment |

| Post-Processing | Easy | Complex | Affects time and cost | Gloss required |

| Brand Appearance | Subtle | Bold | Differentiates positioning | Premium product |

Extension

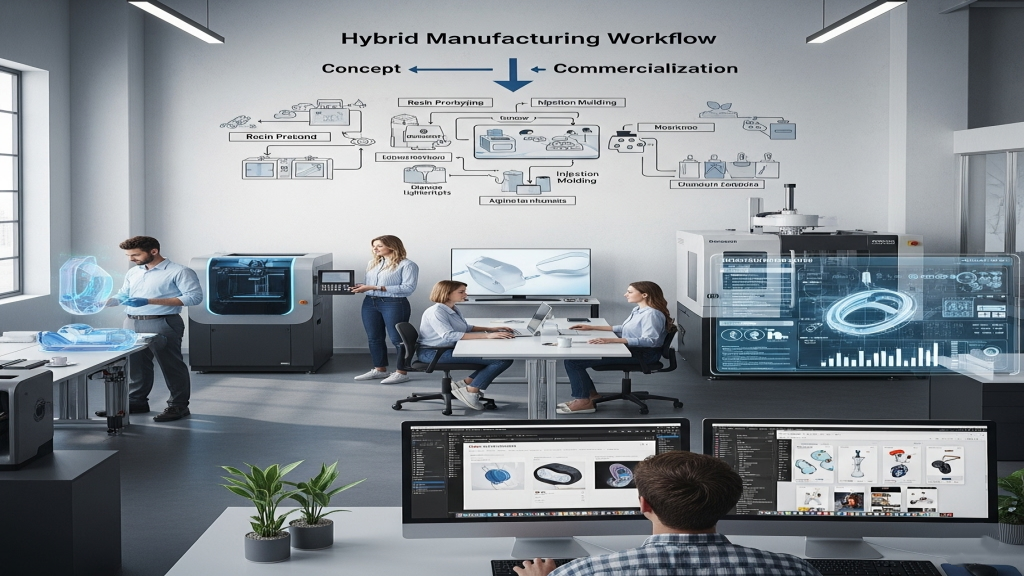

Concave and convex technologies are merging with laser engraving, swappable cores, and digital twins, pushing mold design into smart flexibility. Future text designs will co-optimize with flow behavior, unlocking new commercial opportunities.

1.Laser synergy: Use engraving for textured contrast.

2.Variable cores: Switchable cores for product variants.

3.Digital twin: Simulate flow boundaries before production.

4.Circular materials: Thickness tuning fits recycled plastic use.

Conclusion

Choosing between concave and convex text is more than an aesthetic decision—it is a strategic variable in a business model. From a life-cycle view, concave designs offer better cost-efficiency, while convex types enhance brand value. Assessing production scale, aesthetics, and market demands ensures ROI. In the end, blending both approaches opens diversified product strategies.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!