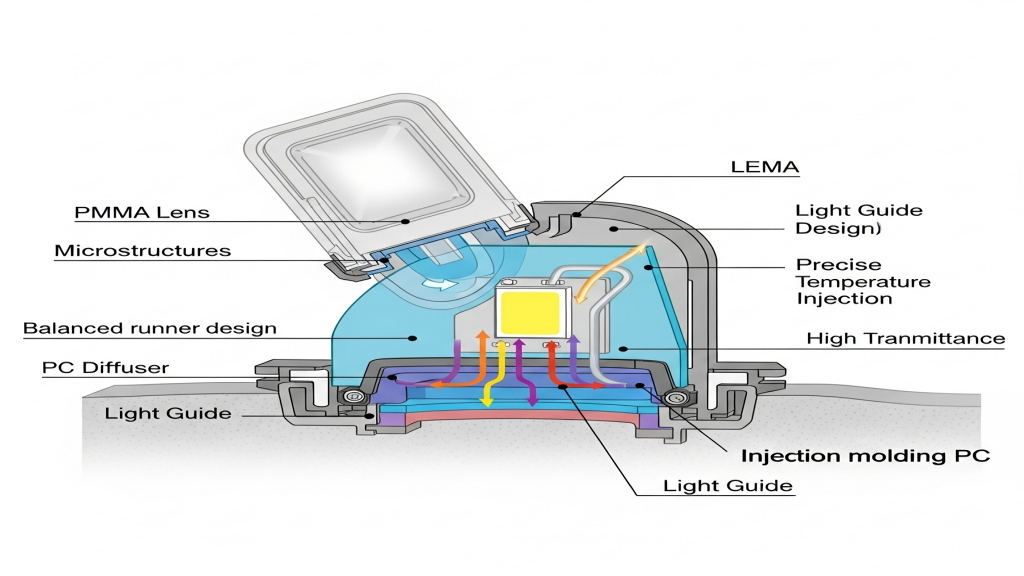

In lighting fixture design, transparent injection-molded parts have become essential for optical performance and structural flexibility. Materials like PC and PMMA offer not only high light transmittance but also excellent weather resistance and flame retardancy.

With the rapid adoption of LED lighting, manufacturers demand greater precision and aesthetics from optical components. Injection molding technology enables integrated manufacturing with superior consistency and visual quality.

How do transparent molded parts enhance lighting efficiency?

Transparent plastic components reduce light loss and are ideal for various optical designs like focusing and diffusing. High-transmittance materials combined with precision molds help maximize luminous efficiency.

- Optical-Grade Material Selection: Use high-transparency plastics like PMMA and PC to improve light passage.

- Microstructure Mold Processing: Use fine mold textures to control light direction.

- Balanced Flow Channel Design: Improves molding uniformity and minimizes air bubble impact.

- Precise Temperature Injection: Ensures stress-free, optically clear parts.

How to ensure durability and stability of transparent parts?

In high-heat or outdoor environments, transparent components must maintain physical integrity and clarity. UV stabilizers and thermal additives significantly extend service life and prevent yellowing.

- UV Protection Additives: Enhance aging resistance with UV modifiers.

- Material Pre-Drying: Controls moisture to prevent haze or microcracks.

- Uniform Wall Thickness: Reduces local stress and deformation risk.

- Surface Coating Treatment: Increases scratch and abrasion resistance.

What are the key injection control points for lighting parts?

Transparent molded lighting parts demand high process control, from injection speed and holding pressure to cooling time. This is particularly crucial for ultra-thin covers and complex lens designs.

- Segmented Injection Speed Control: Prevents flow lines and weld marks.

- Holding Pressure Optimization: Avoids sink marks and ensures consistency.

- Mold Cooling System Design: Precisely manages temperature to avoid warping.

- Nozzle and Hot Runner Matching: Maintains uniform melt delivery.

Performance comparison of transparent materials

| Property | PC | PMMA | PS | Glass |

|---|---|---|---|---|

| Light Transmission | 88–90% | 92–94% | 87% | 95% |

| Impact Resistance | High | Medium | Low | Low |

| Weather Resistance | Good | Fair | Poor | Excellent |

| Moldability | Excellent | Excellent | Moderate | None |

Automatic forming

Transparent injection molding in lighting goes beyond traditional lamp covers, also used in lenses, light guides, and smart modules. With the rise in precision optics, personalized and automated molding solutions are becoming mainstream.

1.Smart In-Mold Monitoring: Enables precise tracking of molding conditions.

2.High-Speed Dual-Shot Molding: Integrates functionality with design aesthetics.

3.Modular Cavity Systems: Supports fast changes for varied product types.

4.Laser Engraved Light Guide: Improves uniformity and enhances design features.

Conclusion

Transparent molded parts are emerging as key players in lighting, thanks to their high light efficiency, design flexibility, and production effectiveness. By integrating premium materials, advanced molding, and smart manufacturing, brands can enhance both performance and appearance. The growing demand for high-performance lighting will further drive the need for custom transparent injection solutions.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!