Introduction

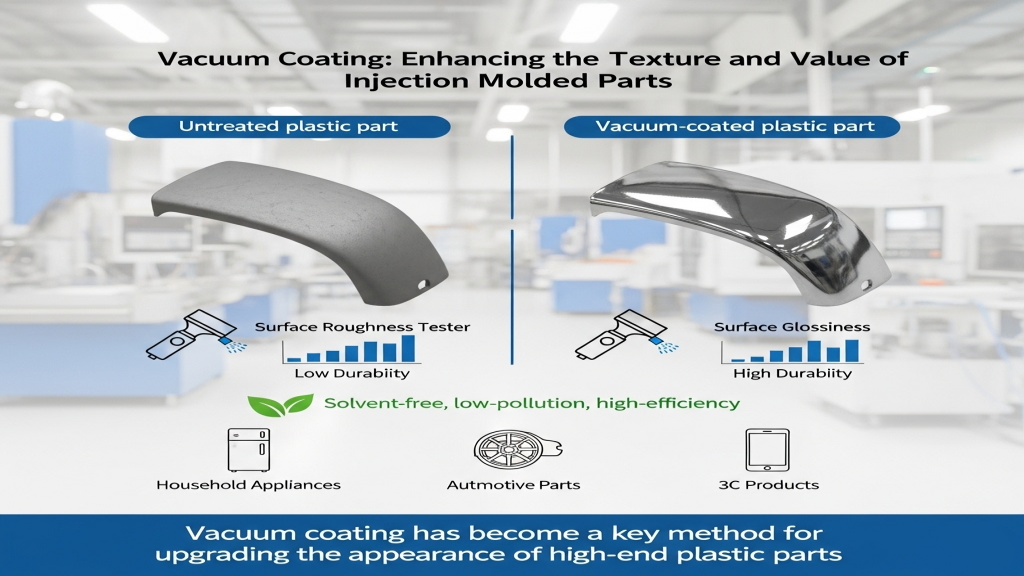

Injection molded products today demand not only functionality but also high-quality surface finishes. Vacuum coating technology meets this demand by depositing a metallic or composite layer on plastic surfaces, significantly improving visual appeal and durability. Vacuum coating has become a key method for upgrading the appearance of high-end plastic parts.

This process offers solvent-free, low-pollution, and high-efficiency advantages, making it ideal for eco-friendly, mass production. It sees broad use in home appliances, automotive components, and 3C products.

What Materials Are Suitable for Vacuum Coating?

Material compatibility is critical in vacuum coating, as different plastics behave differently under vacuum. Common injection materials like ABS, PC, and PP can achieve good coating results with proper surface treatment. Choosing compatible substrates is essential to ensure coating quality.

- ABS offers high compatibility: Naturally polar surface, ideal for direct coating.

- PC requires pre-treatment: Stable substrate but needs plasma to boost adhesion.

- PP needs primer support: Low surface energy, requires primers for successful coating.

- PET suits UV coating layers: Transparent but sensitive to heat, needs special handling.

✨ Selecting the right material is the first step to coating success.

How to Control the Adhesion of the Vacuum Coating Layer?

Adhesion strength directly affects both the appearance lifespan and durability of coated plastic parts. Enhanced adhesion can be achieved through plasma cleaning, primer application, and precise vacuum control. Controlling adhesion is critical to achieving high production yields.

- Primer layer processing: Acts as a bridge to increase bonding strength.

- Surface activation: Plasma or flame cleaning removes surface impurities.

- Clean vacuum environment: Avoids particle contamination in the film.

- Control film thickness: Too thin lacks adhesion, too thick may crack.

🔧 Stable adhesion comes from detailed surface preparation.

How Does Vacuum Coating Improve Appearance?

Vacuum coating offers not only metallic sheen but also mirror, gloss, gradient, and color effects. It provides uniform deposition and strong adhesion—making it a sustainable replacement for traditional plating. It's a major differentiator in 3C electronics and automotive interiors.

- Mirror effect: Achieves high reflectivity with metallic shine.

- Scratch-resistant coating: UV topcoats enhance surface hardness.

- Multicolor options: Target materials define film tones.

- Eco-friendly: No wastewater, compliant with ROHS standards.

🎨 From texture to tone, coating makes plastic parts shine.

Coating Parameters Overview

| Item | Coating Material | Compatible Substrates | Adhesion Level | Gloss Finish | Cost Level | Lead Time | Process Complexity |

|---|---|---|---|---|---|---|---|

| Aluminum Coating | Aluminum | ABS/PC | Medium-High | High Mirror | Low | Fast | Simple |

| Multi-layer PVD | Cr/Ni | PC/ABS | High | High Gloss | Medium-High | Medium | Complex |

| Color Coating | Ti/Cr etc. | ABS/PC | High | Vivid Color | High | Slow | High |

| UV Topcoat | UV Resin | Universal | Very High | Scratch-Proof | Medium | Medium | Medium |

How Do We Offer One-Stop Coating Solutions?

We integrate injection molding, surface preparation, and vacuum coating to provide full-stack services from material selection and mold development to mass production and post-processing. Our team ensures stable process control and shortens product development time.

1.Customized coating formulation: Recommended based on your product positioning.

2.Mold-coating synergy: Designed with coating thickness and adhesion in mind.

3.Mass production ready: Over 300K units/month capacity ensures timely delivery.

4.Technical support: From design to shipment, we've got you covered.

Conclusion

Vacuum coating for injection molded products is now a critical method for enhancing both appearance and performance—particularly in consumer electronics and automotive industries. Material compatibility, process control, and adhesion handling are vital to achieving optimal results. With our proven injection + coating system, customers save on costs and development time—helping them gain competitive edge in fast-paced markets.

For expert assistance in implementing vacuum coating for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!