Introduction

Agricultural chemical tanks are continuously exposed to pesticides, fertilizers, and cleaning agents, placing extremely high demands on corrosion resistance and long-term material stability. These requirements directly affect equipment service life, operational safety, and overall reliability in agricultural machinery applications. Insufficient corrosion resistance often emerges as a hidden cost driver during mid-to-late service stages.

As agricultural operating environments become more complex, relying solely on material datasheets is no longer sufficient to mitigate real-world risks. Structural design, injection molding processes, and quality control systems now play equally critical roles. Addressing corrosion risks from the design and manufacturing stages has become a strategic priority for agricultural equipment manufacturers.

Why Do Agricultural Chemical Tanks Frequently Suffer Corrosion Failures?

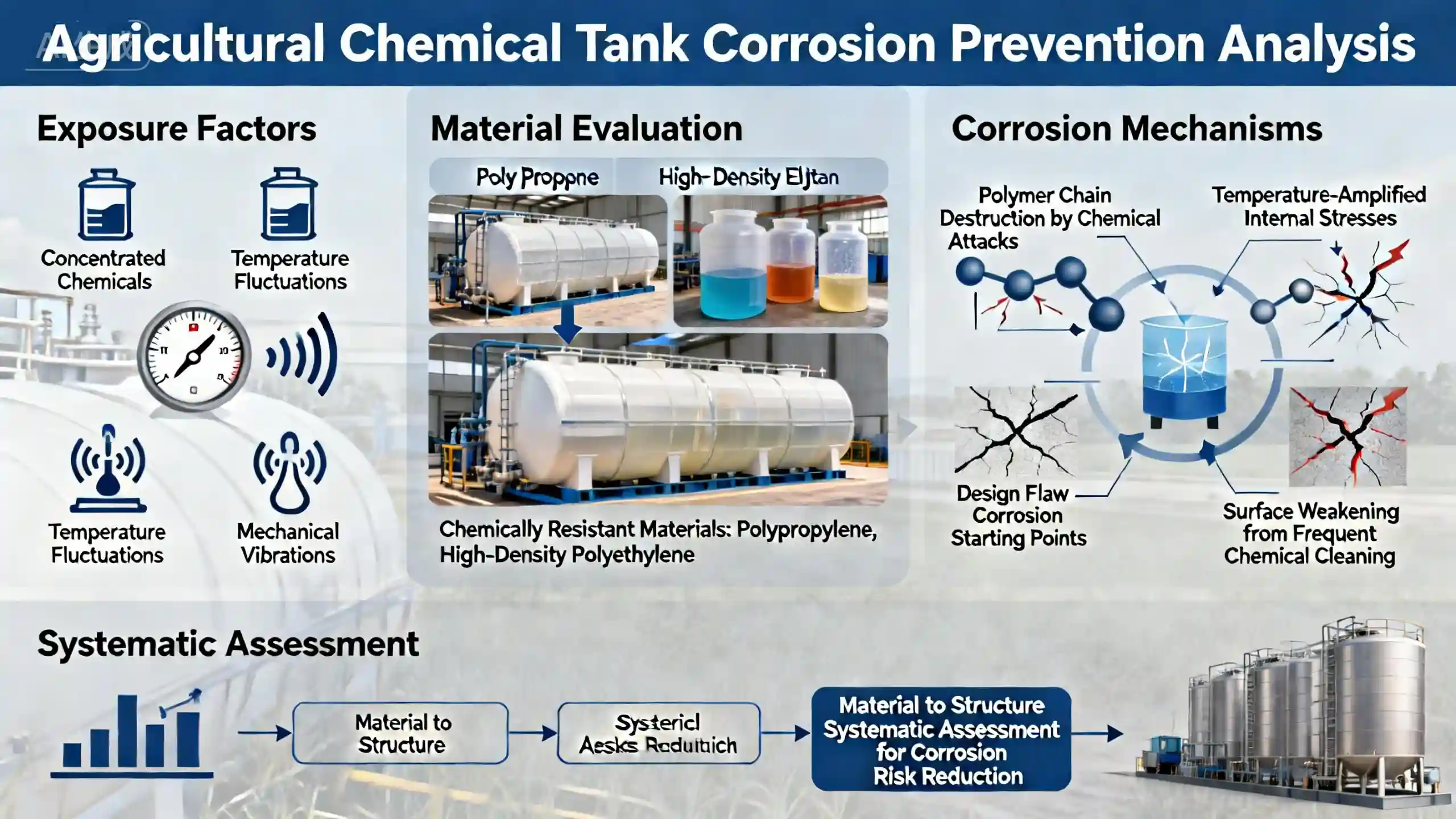

In real operating conditions, agricultural chemical tanks are subjected to prolonged exposure to concentrated chemicals while simultaneously experiencing temperature fluctuations and mechanical vibration. This combination accelerates material aging and stress-induced corrosion. If chemical resistance is overlooked during material selection, downstream corrective actions become costly and inefficient. Xiamen Ruicheng evaluates material behavior under simulated working conditions using chemical-resistant polypropylene and HDPE materials to prevent early-stage risks.

Cumulative chemical attack: Active components in agrochemicals gradually disrupt polymer chains, leading to embrittlement.

Environmental temperature variation: Daily and seasonal temperature shifts amplify internal stresses and material degradation.

Structural stress concentration: Poorly designed ribs and corners become initiation points for corrosion.

Cleaning process impact: Frequent chemical cleaning further weakens surface stability over time.

🧪 Systematic evaluation from material to structure is the foundation for reducing corrosion-related failures.

How Do Injection Molding Processes Affect Corrosion Resistance and Service Life?

Injection molding parameters directly influence internal density and residual stress levels within molded parts, both of which are closely linked to corrosion performance. Process instability can cause even corrosion-resistant materials to fail prematurely in real applications. In agricultural projects, Xiamen Ruicheng stabilizes performance by controlling melt flow behavior and polymer crystallinity.

Shear rate optimization: Controlled shear promotes uniform molecular orientation and reduces chemical permeation.

Cooling rate coordination: Balanced cooling minimizes internal stress accumulation.

Mold surface treatment: High-quality cavity finishes reduce microvoids and surface defects.

Batch consistency management: A stable processing window ensures repeatable corrosion resistance across production runs.

⚙️ Corrosion resistance is not a single process setting, but the result of end-to-end process stability.

How Can Structural Design Reduce Corrosion and Leakage Risks?

Structural design is one of the most overlooked yet most impactful elements in corrosion-resistant solutions. Optimized wall thickness and flow path design significantly reduce chemical retention and localized attack. Xiamen Ruicheng applies finite element analysis and mold flow simulation during early development to identify potential weak points.

Uniform wall thickness: Prevents stress concentration and corrosion initiation.

Smooth radii and transitions: Reduces chemical stagnation zones.

Optimized rib layout: Balances structural strength while avoiding corrosion traps.

Reinforced interface zones: Critical connection areas are separately validated to minimize leakage risks.

🧩 A well-designed structure acts as an invisible yet powerful layer of corrosion protection.

Comparison of Corrosion-Resistant Solutions for Agricultural Chemical Tanks

| Solution Type | Material System | Chemical Stability | Structural Reliability | Maintenance Cost |

|---|---|---|---|---|

| Conventional molding | Standard PP | Medium | Medium | High |

| Modified material approach | Modified PP | High | Medium | Medium |

| Process-enhanced solution | HDPE | High | High | Medium |

| Integrated system solution | Customized compounds | Very High | Very High | Low |

Selecting the right system-level solution allows manufacturers to significantly reduce long-term maintenance and replacement costs.To evaluate which approach best fits your application, feel free to contact us.

An Integrated Corrosion-Resistance Strategy from Material to Delivery

The true corrosion resistance of agricultural chemical tanks is reflected in the coordinated performance of material selection, structural design, process control, and quality assurance. Xiamen Ruicheng embeds corrosion resistance requirements throughout the entire injection molding development cycle.

1.Upfront material assessment: Matching material systems to actual chemical exposure conditions.

2.Collaborative structural design: Reducing corrosion and leakage risks while maintaining strength.

3.Stable process control: Ensuring consistency and traceability in mass production.

4.Delivery risk management: Verification and validation mechanisms to minimize uncertainties during use.

Frequently Asked Questions (FAQ)

Question: What is the core advantage of your corrosion-resistant injection-molded agricultural chemical tank solution?

Answer: The solution integrates material performance, structural optimization, and process stability to ensure long-term reliability under continuous chemical exposure.

Question: What information is required to quickly initiate a quotation and evaluation?

Answer: Providing chemical type, operating environment, tank capacity, and annual demand enables Xiamen Ruicheng to deliver a targeted evaluation efficiently.

Question: How do lead time and cost vary with different order volumes?

Answer: Small batches support validation and pilot production, while larger volumes benefit from optimized unit costs and stable delivery schedules.

Question: How are corrosion or leakage issues handled after delivery?

Answer: Clear evaluation standards and traceability systems allow rapid root-cause identification and corrective action.

Question: Can you support customized solutions for special chemicals or extreme environments?

Answer: Yes, material formulations and structural designs can be adjusted based on specific operating conditions and usage requirements.

Conclusion

Corrosion resistance in agricultural chemical tanks is fundamentally a system-level capability integrating material science, design expertise, and manufacturing discipline. Only a holistic solution can effectively reduce lifecycle risks and ownership costs. By partnering with an experienced injection molding manufacturer like Xiamen Ruicheng, agricultural equipment producers can achieve a stronger balance between durability, cost efficiency, and delivery reliability.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!