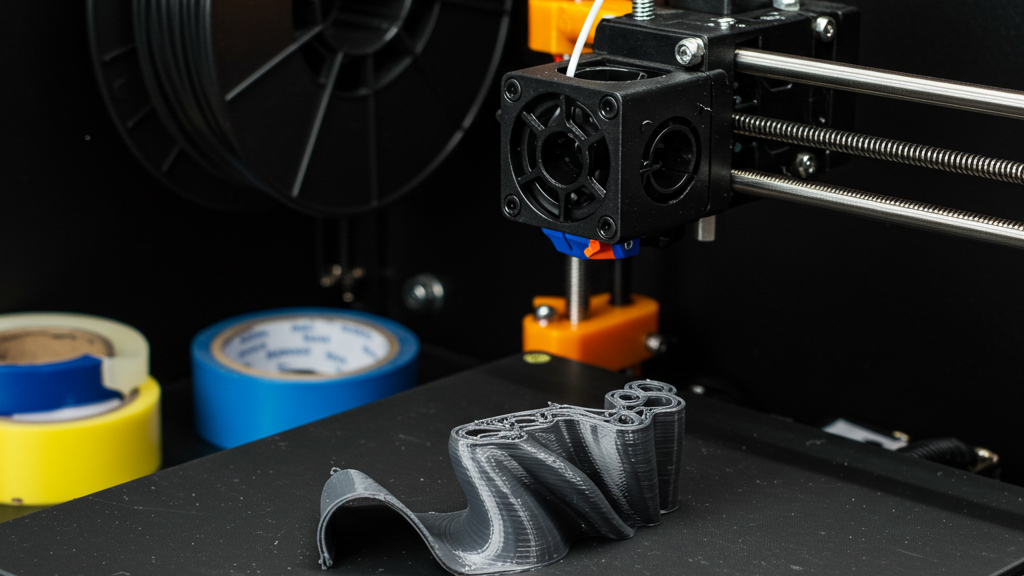

ABS filament is widely used in 3D printing due to its toughness and durability. However, its cooling shrinkage characteristics often lead to warping of printed parts, affecting accuracy and quality, and in severe cases, leading to printing failures. Therefore, understanding the causes of warping and mastering effective handling methods is crucial.

ABS material properties and various printing factors may cause warping. These factors interact with each other, making the warping problem relatively complex. How to accurately implement measures to effectively inhibit and eliminate ABS printing warping? We will focus on specific solutions, covering pre-printing preparation, printing process control, and post-printing treatment, providing a comprehensive response strategy.

What is the root cause of ABS warping?

Warping, a common problem in 3D printing, is particularly prominent with ABS materials. Understanding how the material properties of ABS interact with the printing process to ultimately lead to warping is crucial for us to develop effective solutions.

- Significant Thermal Shrinkage: The significant volume shrinkage of ABS material during cooling is the main internal cause of warping.

- Large Coefficient of Thermal Expansion: ABS has a higher coefficient of thermal expansion compared to other materials, making it more sensitive to temperature changes and prone to uneven shrinkage.

- Uneven Cooling Rate: Inconsistent cooling rates in different areas during the printing process lead to different degrees of shrinkage, generating internal stresses that cause warping.

- Poor Layer Adhesion (Manifests during Warping): Excessive shrinkage stress may overcome the layer bonding force, causing the bottom to detach, exacerbating the warping phenomenon.

How to Prevent and Control ABS Warping?

Prevention is better than cure. For ABS materials prone to warping, it is crucial to adopt proactive prevention and control strategies. By optimizing the printing environment, adjusting printing parameters, and cleverly designing the model, we can minimize the risk of warping and obtain dimensionally accurate, high-quality ABS prints. The following content will detail these key prevention and control methods.

- Optimize Printing Environment and Build Plate Adhesion: Providing a constant temperature environment, heating the build plate, and using auxiliary materials can effectively enhance adhesion, slow down cooling, and prevent warping.

- Adjust Key Printing Parameters: Reducing printing speed, optimizing layer height and fan cooling, and adjusting infill density and wall thickness can reduce stress and shrinkage during the printing process.

- Reasonably Design 3D Models: Avoiding large flat bottoms, adding skirts, brims, or rafts, and splitting large parts for printing can effectively reduce the risk of warping.

- Select Appropriate ABS Material and Dry the Filament: Selecting low-shrinkage ABS and keeping the filament dry helps reduce warping from the material source and printing quality.

How to Remedy Warped ABS Parts?

When ABS prints unfortunately warp, we can still try to repair them with some post-processing methods. These methods each have their own advantages and disadvantages and are suitable for different degrees and types of warping. The following content introduces several commonly used remedies for ABS warped parts, providing users with some ideas and methods to salvage printing results.

- Local Heating and Correction with Hot Air Gun or Heat Blower: By locally heating and softening the warped area and applying pressure, minor warping can be corrected.

- Secondary Heating and Flattening on Heat Bed or Heated Platform: Reheating the warped part on a heated platform and applying heavy pressure can help restore overall flatness.

- Chemical Solvent Softening and Flattening: Softening the ABS surface with chemical solvents and then flattening is an effective but requires careful operation.

- Cutting and Reassembling: For severely warped parts, consider cutting off the deformed parts and reassembling them with other parts or reprinting them separately.

Comparison between ABS and other 3D printing materials

| Property | ABS (Acrylonitrile Butadiene Styrene) | PLA (Polylactic Acid) | PETG (Polyethylene Terephthalate Glycol) | Nylon (Polyamide) |

|---|---|---|---|---|

| Warping Tendency | High | Low | Medium | High |

| Strength | Good | High but Brittle | Good | Excellent |

| Toughness | Good | Poor | Good | Excellent |

| Heat Resistance | Approx. 85-100°C | Approx. < 60°C | Approx. 70-80°C | Good, Varies by Grade |

| Print Difficulty | High, Heated Bed Required, Warping Prone | Low, Easy to Print | Medium, Heated Bed Required, Stringing Possible | High, High Temp., Hygroscopic |

| Main Applications | Functional Parts, Enclosures | Prototypes, Models, Decorations | Functional Prototypes, Mechanical Parts, Food Containers | Wear-Resistant Parts, Gears |

Other Methods to Improve ABS Warping

In some specific application scenarios, it may be possible to provide more effective warping solutions, bringing new possibilities to ABS users who pursue higher printing quality. Continuously paying attention to advances in materials science and printing technology will help us more comprehensively address the challenge of ABS warping.

1.Use ABS Slurry: ABS slurry can significantly improve first layer adhesion and resist warping.

2.Use Tape for Fixation: Using double-sided tape or special anti-warping tape can firmly fix the print and reduce bottom warping.

3.Optimize Bottom Design: Optimizing the bottom contact design of the model can increase the adhesion area, disperse shrinkage stress, and reduce warping.

4.Change Build Plate Material: Trying different build plate materials or surfaces can provide better adhesion and effectively reduce ABS warping.

Conclusion

In summary, the warping problem of ABS filament is a common and complex challenge in the 3D printing process, fundamentally due to the significant thermal shrinkage of ABS material itself, the large coefficient of thermal expansion, and the uneven cooling rate during printing. To effectively address this issue, we can start from multiple dimensions.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!