Introduction

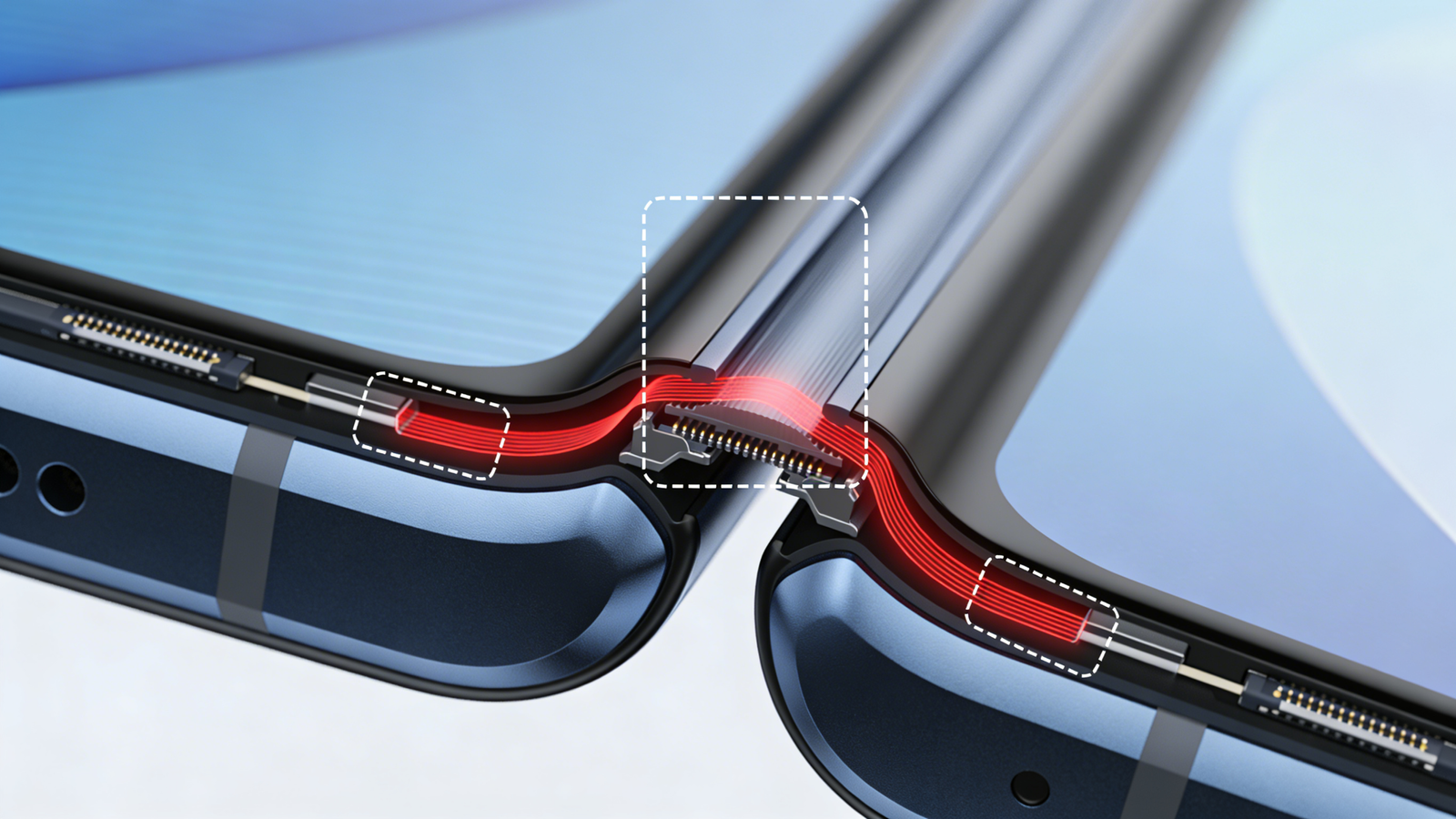

The rapid adoption of foldable devices has pushed flexible structural components from being merely functional to being mission-critical for long-term reliability. The ability to withstand repeated bending without permanent deformation has become a decisive factor in product lifespan.

From Xiamen Ruicheng’s project experience, bending durability is never guaranteed by material selection alone. Only when material behavior, structural design, and injection molding processes are aligned can flexible injection parts remain stable throughout mass production and real-world use.

Why Do Flexible Parts in Foldable Devices Fail Under Repeated Bending?

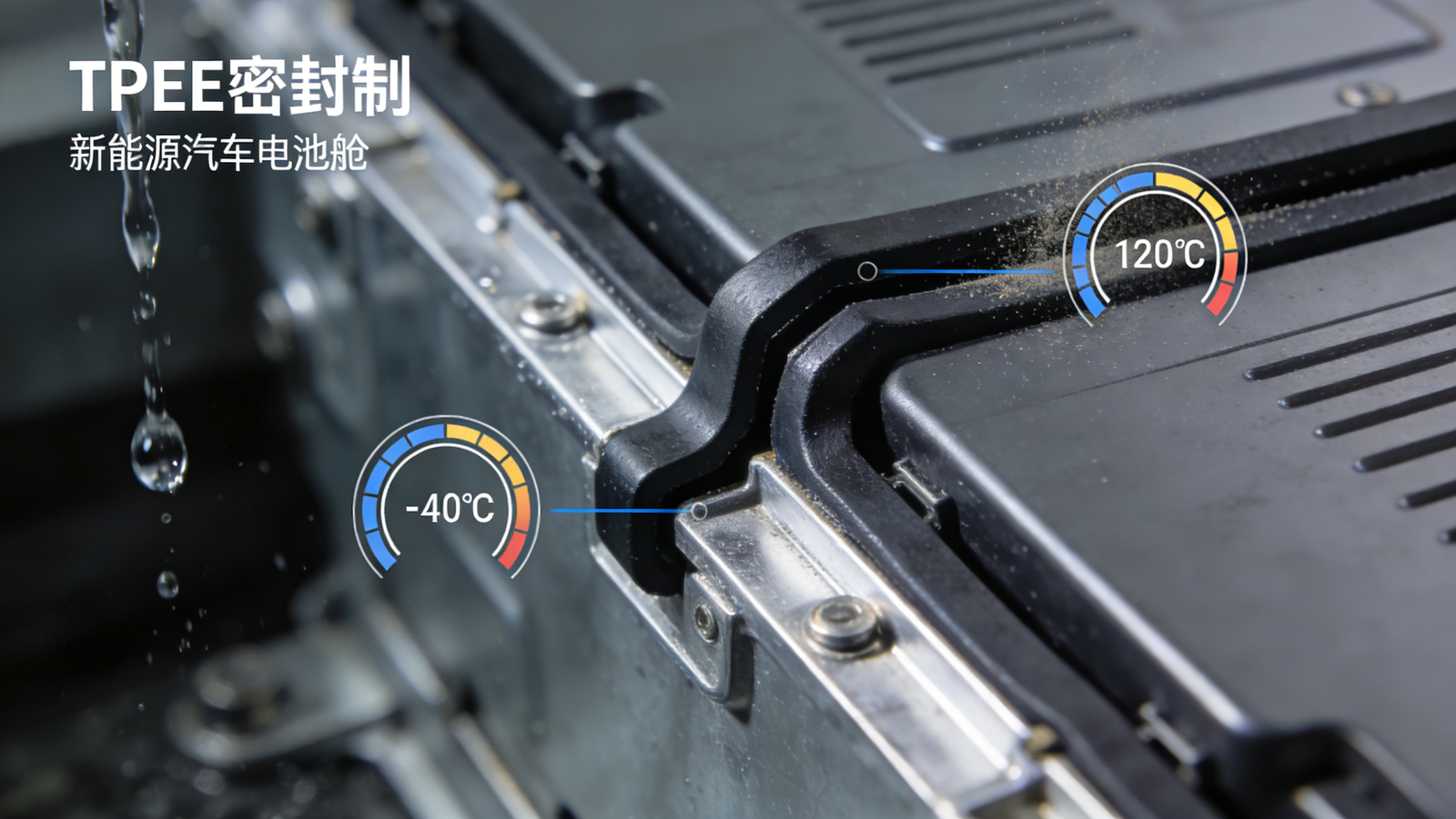

During frequent folding cycles, flexible injection molded parts are exposed to continuous alternating stress, which gradually accumulates deformation if fatigue resistance is insufficient. TPEE combines rigid segments for structural support and soft segments for stress dissipation, allowing it to maintain integrity under long-term bending. By integrating TPEE material characteristics with proven injection molding processing, the risk of permanent deformation can be significantly reduced.

Fatigue response: TPEE releases cyclic stress efficiently, preventing localized stress concentration.

Structural stress distribution: Optimized radii and wall thickness ensure uniform load during folding.

Environmental adaptability: Stable elasticity is maintained across temperature and humidity changes.

Production consistency: Controlled molding windows ensure repeatable performance across batches.

🙂 This is the fundamental reason why foldable devices demand higher-performance flexible injection parts.

How Do TPEE Flexible Injection Parts Retain Elastic Recovery After High-Frequency Folding?

In real applications, loss of rebound force often occurs earlier than visible cracking, making it a hidden reliability risk. Xiamen Ruicheng ensures stable elastic recovery in TPEE flexible injection molded parts through material grade selection and process optimization. By combining TPEE elastomer structure with custom flexible injection molding, elastic recovery is treated as a primary validation criterion.

Molecular chain recovery: Soft segments rapidly return to their original configuration after unloading.

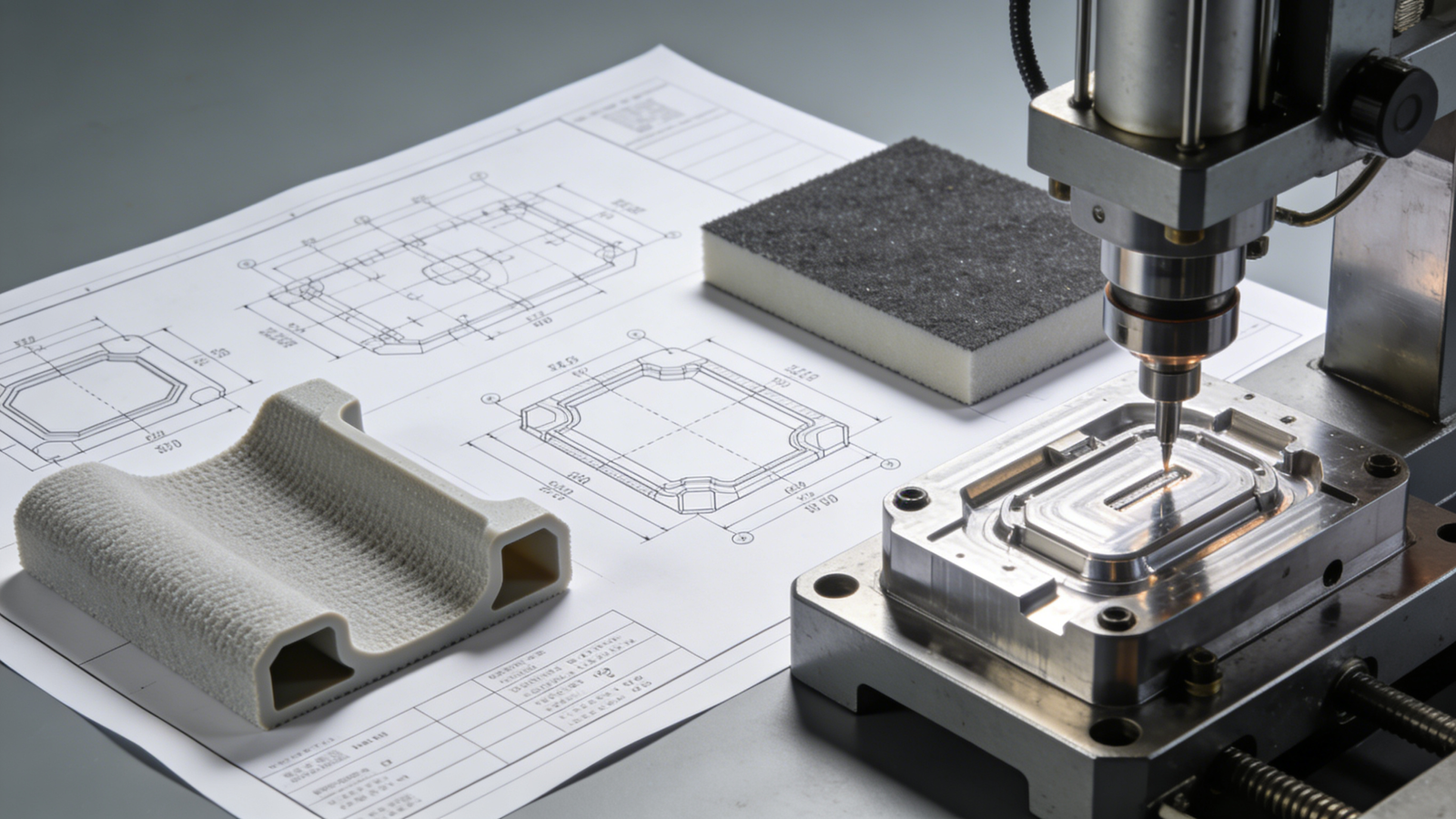

Mold constraint design: Precision cavities guide consistent elastic deformation paths.

Processing temperature control: Prevents degradation of elastic segments caused by overheating.

Lifecycle validation: Multiple bending-cycle tests are completed prior to mass production.

🔁 Stable rebound performance is the result of systematic engineering, not coincidence.

How Does Injection Molding Processing Affect Long-Term Bending Life of TPEE Parts?

Many foldable device failures are caused not by incorrect material choice, but by uncontrolled processing conditions that prematurely degrade performance. At Xiamen Ruicheng, shear rate and cooling profiles are tightly managed to preserve the internal structure of TPEE during injection molding. By applying injection flow control together with precision injection molding, long-term bending durability can be effectively extended.

Shear stress management: Reduced flow-induced orientation protects molecular integrity.

Balanced cooling rates: Minimizes residual stress that could affect bending performance.

Stable molding window: Ensures every production run stays within validated parameters.

Process traceability: Recorded data enables rapid identification of potential risks.

🛠️ Process discipline determines whether flexible parts can endure real-world usage.

Key Material and Performance Comparison for Foldable Device Flexible Parts

| Comparison Criteria | TPEE Injection Parts | TPU Parts | Silicone Parts | Conventional Rubber |

|---|---|---|---|---|

| Elastic Stability | High | Medium | High | Medium |

| Fatigue Resistance | Excellent | Good | Good | Average |

| Injection Consistency | Excellent | Good | Low | Low |

| Mass Production Fit | Strong | Medium | Weak | Weak |

If you are reassessing long-term reliability strategies for foldable devices, now is the right moment to revisit your material and process choices—contact us

Key Control Points From Sampling to Mass Production

In foldable device projects, the highest risk often lies between successful prototyping and unstable mass production. Xiamen Ruicheng ensures that the bending performance of TPEE flexible injection molded parts remains consistent from validation to large-scale manufacturing. This requires coordinated control over materials, tooling, and molding processes.

1.Prototype stage: Simulated real folding conditions are used to validate bending life.

2.Tooling stage: Structural features are designed to eliminate stress concentration.

3.Pilot production: Small-batch data confirms process window stability.

4.Mass production: Continuous monitoring ensures long-term consistency.

Frequently Asked Questions (FAQ)

Question: What are the core performance advantages of your TPEE flexible injection molded parts for foldable devices?

Answer: We define bending durability and elastic stability as baseline performance criteria, supported by material selection, structural optimization, and controlled injection processes.

Question: What information is required to initiate a customized foldable component project?

Answer: We recommend providing application location, bending angle, frequency, and target service life, enabling rapid feasibility evaluation.

Question: How do order volume levels affect MOQ and lead time?

Answer: Sampling and small-batch production remain flexible, while mass production lead times are optimized based on annual demand planning.

Question: How are quality deviations handled after delivery?

Answer: A complete traceability and revalidation mechanism allows quick issue identification and corrective action.

Question: Do you support customization for special folding conditions?

Answer: Yes, customization feasibility, lead time, and cost are evaluated based on actual operating conditions and verified through testing.

Conclusion

The requirements for flexible parts in foldable devices have evolved from simple flexibility to long-term structural stability. Only when material behavior, structural design, and injection molding processes are aligned can TPEE flexible injection molded parts truly resist deformation under repeated bending.By leveraging real-world manufacturing experience, Xiamen Ruicheng supports customers at every decision stage, helping them mitigate hidden risks and build durable, competitive foldable products.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!