TPO (Thermoplastic Olefin) materials have become widely used in injection molding due to their excellent elastic properties. This material's elasticity provides outstanding performance in various fields, and through the injection molding process, its application can be precisely achieved.

As technology advances, the versatility and potential of TPO continue to expand, making it an essential component in many products.

How Does Elasticity Affect TPO Injection Molding Performance?

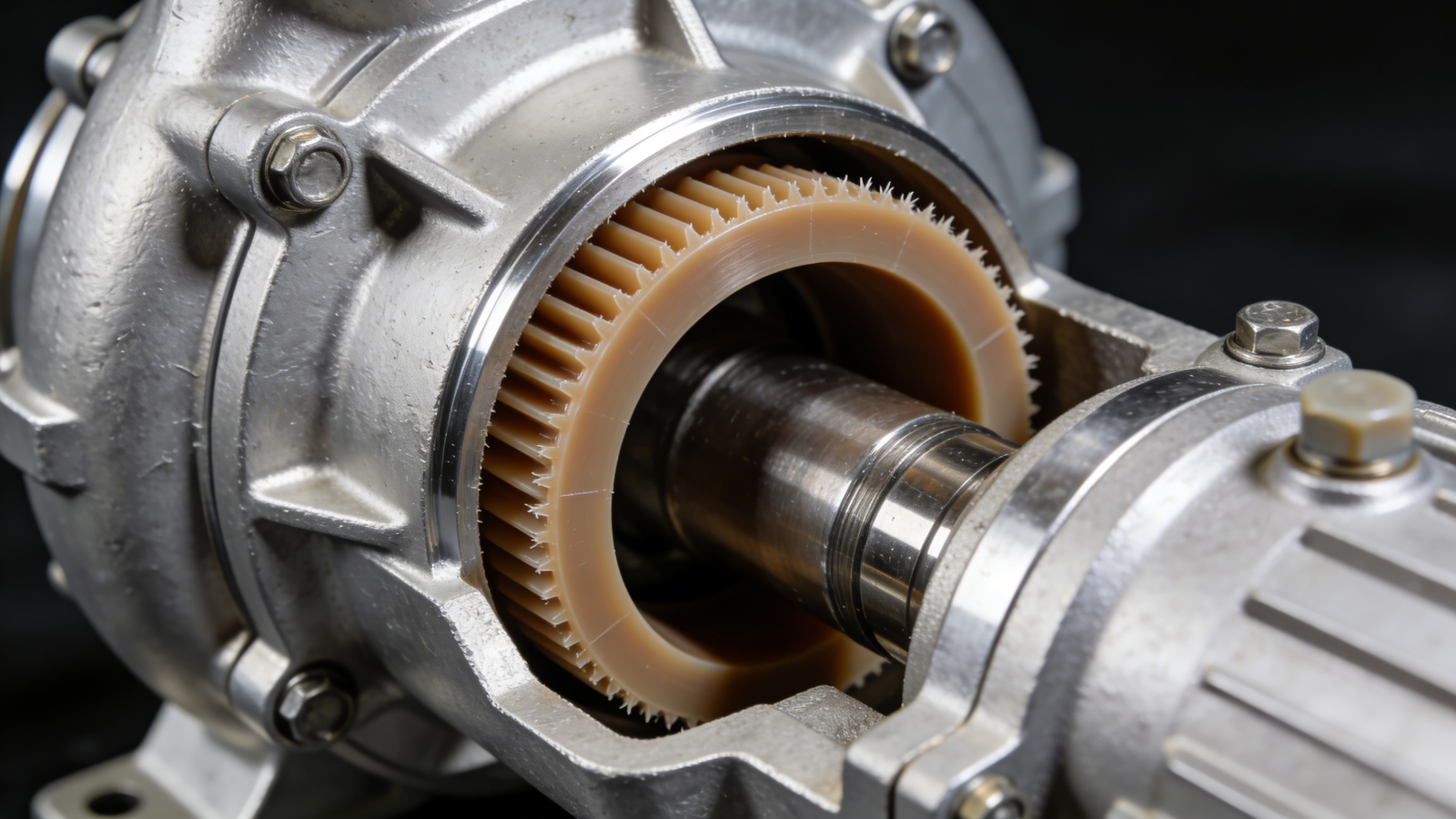

TPO's elasticity gives it unique advantages during the injection molding process. This material can undergo elastic deformation under external force and return to its original shape, ensuring the stability and durability of the product. It is this characteristic that makes TPO perform exceptionally well, especially in products requiring certain elasticity.

- Impact Resistance: TPO materials effectively resist external impacts.

- Rebound Performance: Learn more about TPO rebound performance.

- Fatigue Resistance: Maintains elasticity over long-term use.

- Stability: Dive into material stability.

How Does TPO Improve the Longevity of Injection Molded Parts?

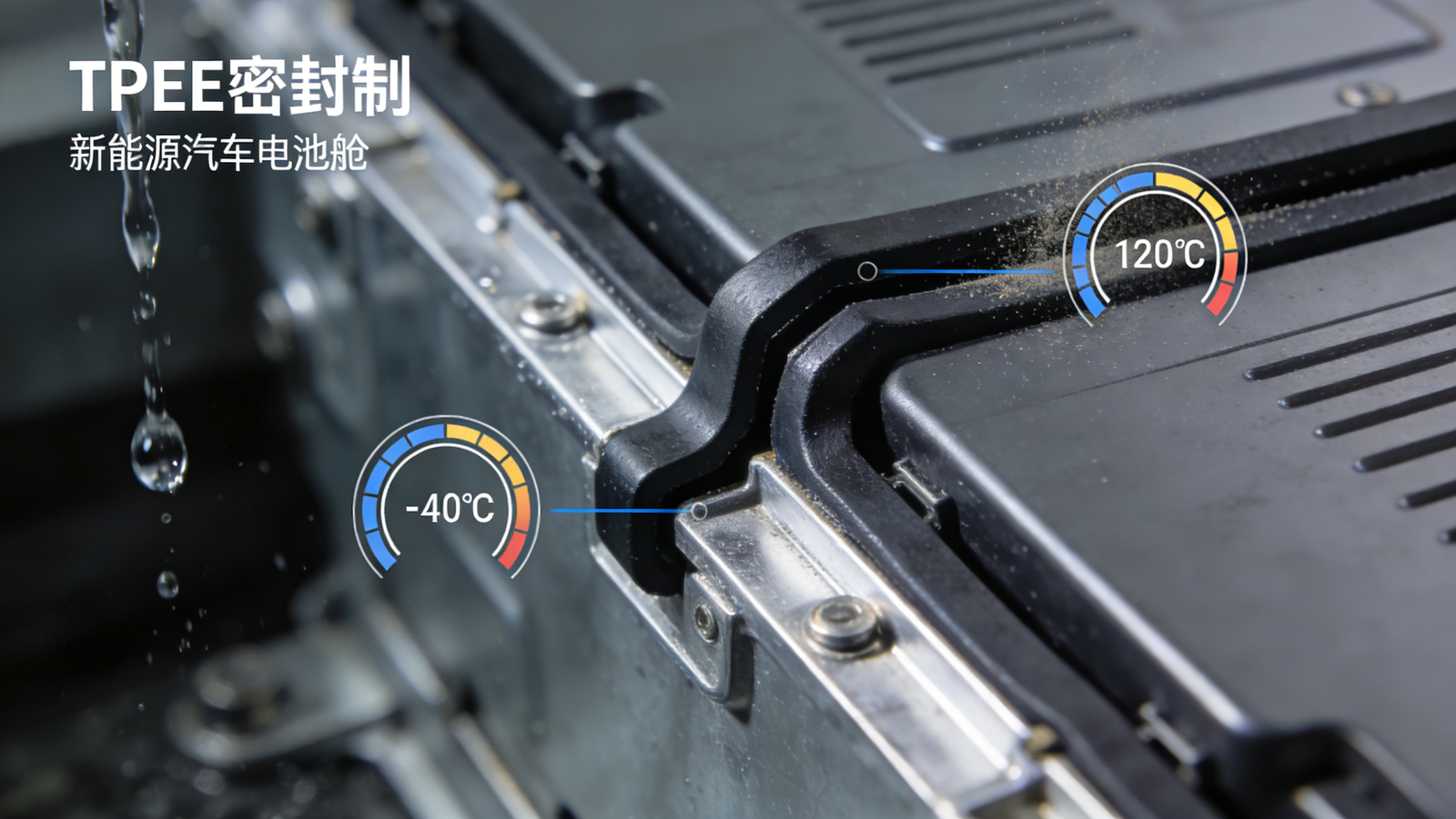

TPO’s elastic properties directly enhance the durability of injection-molded parts, allowing them to perform excellently in long-term use. The material’s resistance to aging and UV rays allows TPO injection molded parts to maintain good performance even in harsh environments. This characteristic is particularly crucial for applications outdoors or in high-temperature environments.

- High-Temperature Resistance: Ensures stable use in high-temperature environments.

- UV Resistance: Learn more about UV resistance

- Weather Resistance: Performs well in various environmental conditions.

- Oxidation Resistance: Extends service life.

The Cost-Effectiveness of TPO Materials

The elasticity of TPO injection molded parts not only enhances product performance but also effectively reduces production costs. Due to its relatively low raw material cost and excellent processing capabilities, TPO has become a crucial choice in manufacturing. Combined with injection molding, TPO enables high-efficiency, low-cost production.

- Production Efficiency: Enhances injection molding production efficiency.

- Low Material Cost: Learn about TPO cost advantages

- High Value for Money: Achieves the best balance between performance and cost.

- Production Flexibility: Adapts to various production requirements.

TPO vs Other Materials

| Feature | TPO Material | Rubber | Polyurethane | Polycarbonate |

|---|---|---|---|---|

| Elasticity | High | Medium | High | Low |

| Durability | High | Medium | High | Medium |

| High-Temperature Resistance | Strong | Medium | Strong | Weak |

| Cost | Low | Medium | High | Medium |

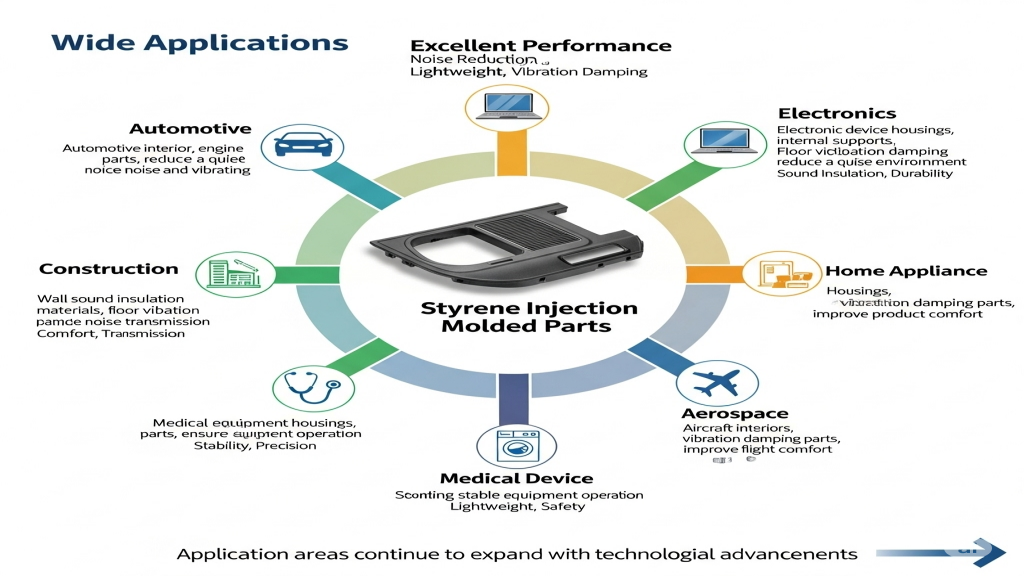

Expanding Application Fields

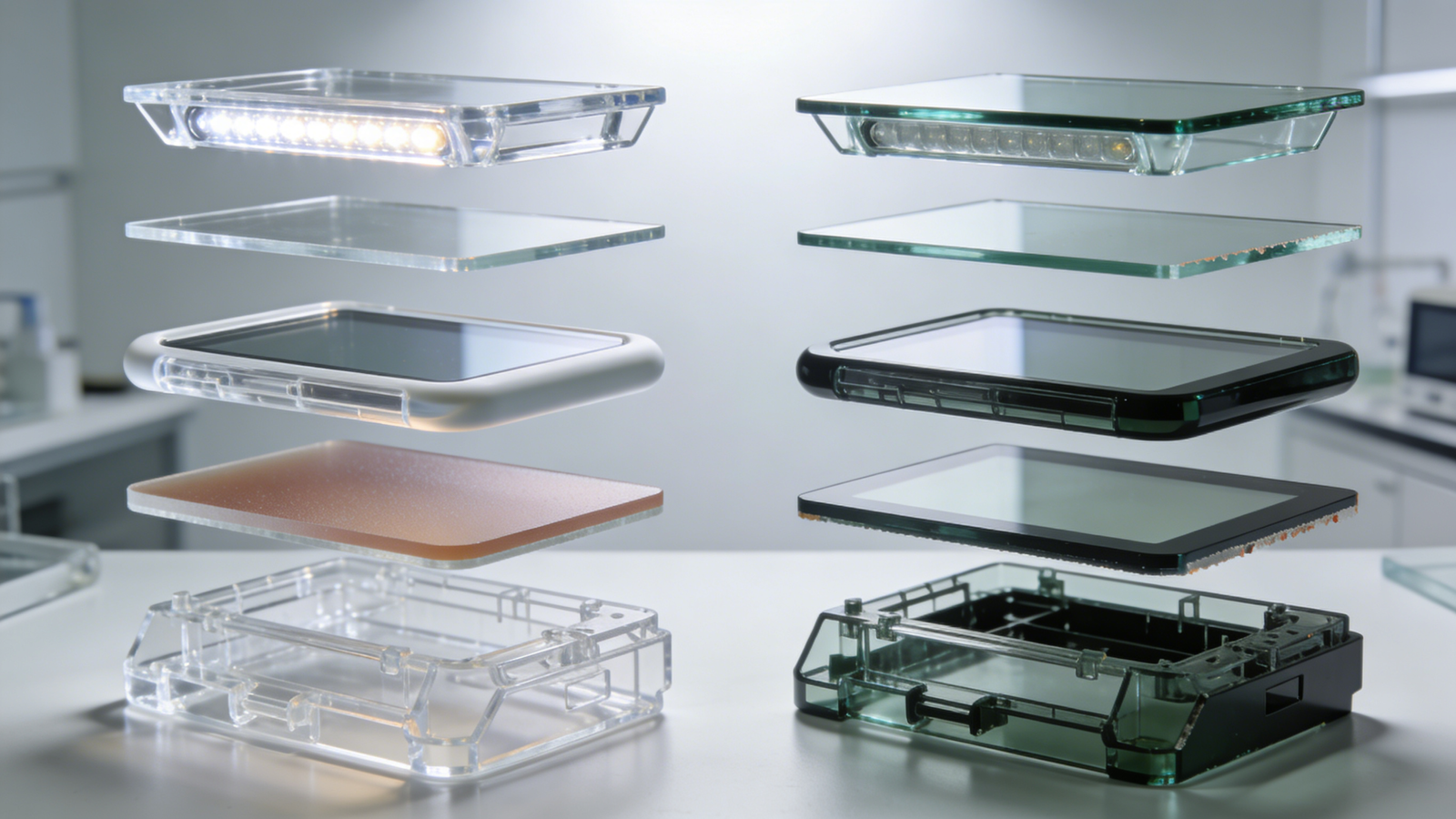

The elasticity of TPO makes it suitable for a wide range of industries, especially in automotive, home appliances, and consumer electronics. With increasing demand for high-performance, low-cost materials, the market demand for TPO continues to rise, and injection molding technology makes its application more precise and efficient.

1.Automotive Industry: Enhances vehicle safety and comfort.

2.Home Appliances: Improves durability and performance of home appliances.

3.Consumer Electronics: See TPO applications in consumer electronics.

4.Packaging Materials: Enhances durability and impact resistance of packaging materials.

Conclusion

TPO's elastic properties, through the injection molding process, have been widely applied and have become an important choice for enhancing product performance and reducing production costs. The versatility and cost-effectiveness of this material provide significant market advantages across various industries. As technology continues to develop, the application fields of TPO will expand further, offering solutions for more industries.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!