Plastic rivets, as an emerging material, are widely used in the manufacturing industry, especially in replacing traditional metal fasteners. They are becoming the preferred choice for an increasing number of manufacturers due to their lightweight and corrosion-resistant properties. By using plastic rivets, companies can significantly reduce production costs and improve the overall performance and sustainability of their products.

With advancements in injection molding technology, the quality and strength of plastic rivets have been continuously improved, gradually meeting the diverse needs of metal fasteners. Plastic rivets not only reduce transportation and storage costs but also shorten production cycles, providing more profit margins for companies.

Why can plastic rivets replace metal fasteners?

The widespread adoption of plastic rivets is mainly due to their lightweight and multifunctional characteristics. They not only reduce the overall product weight but also have high corrosion resistance, making them very suitable for environments with high humidity or corrosive elements. Therefore, using plastic rivets can effectively reduce maintenance costs.

- Cost-effectiveness: Plastic rivets are cheaper than metal rivets and can reduce procurement costs.

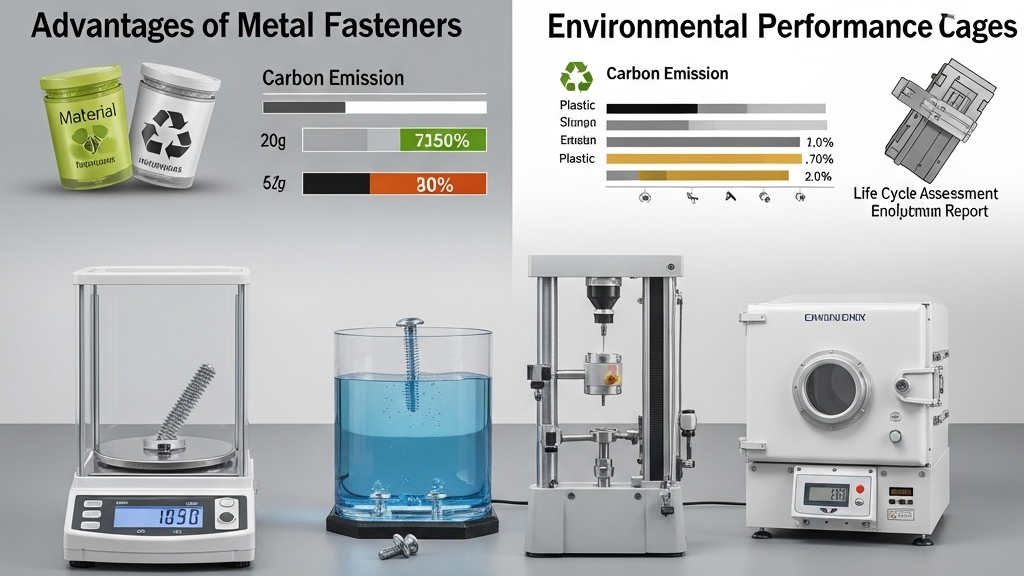

- Environmental performance: Plastic alternatives to metal materials are more environmentally friendly, contributing to sustainable development.

- Efficient production: Injection molding makes the production process of plastic rivets more efficient.

- Corrosion resistance: Plastic rivets are corrosion-resistant and suitable for harsh environments.

How durable are plastic rivets?

The durability of plastic rivets is a key concern, especially when they are used to replace metal fasteners. Although plastic materials may not be as strong as metal in some areas, many plastic rivets' performances are already sufficient for daily use. Proper plastic formulations can enhance their compressive strength and durability, making them a long-lasting and stable choice.

- Suitable for low-load environments: Plastic rivets used in low-load environments are durable enough, avoiding metal fatigue.

- Oxidation resistance: Oxidation resistance: Plastic rivets are not easily oxidized and can effectively extend service life.

- Strength control: Formulations can be improved to increase the tensile strength of plastic rivets.

- Wide range of applications: Plastic rivets perform well in non-high-temperature and non-high-pressure conditions.

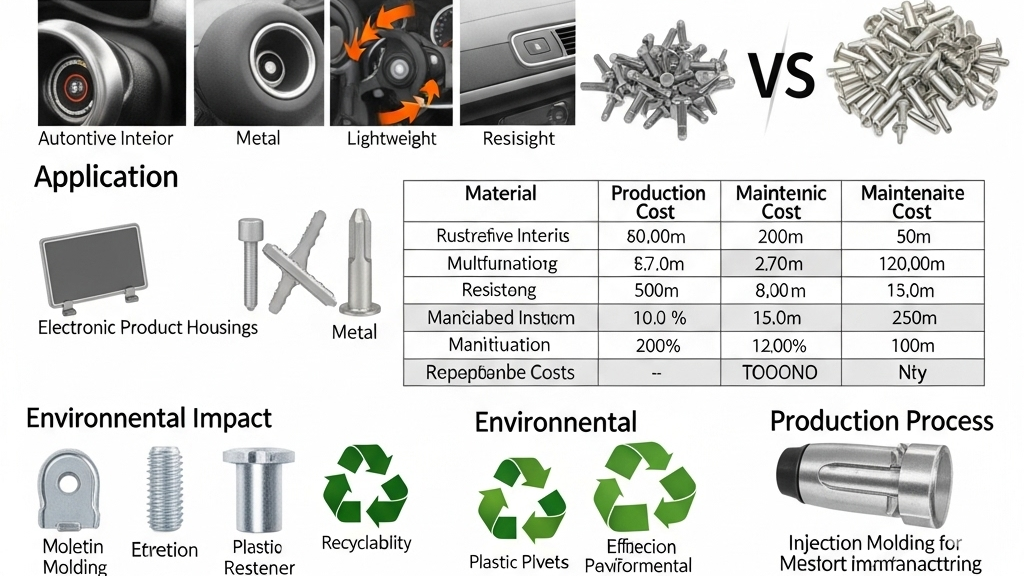

How do plastic rivets perform in different applications?

Plastic rivets perform excellently across multiple industries, especially in automotive and electronics manufacturing. Due to their unique properties, plastic rivets stand out in terms of reducing overall product weight and cutting costs. Even in complex production environments, plastic rivets maintain their stability and reliability.

- Automotive industry: Plastic rivets in the automotive sector replace metal rivets to reduce vehicle weight.

- Electronic products: Plastic rivets are used in electronic devices to improve product shock resistance.

- Home appliances: Plastic rivets are widely used in home appliances to improve appearance and reduce costs.

- Medical devices: Plastic rivets' lightweight and safety make them the preferred choice in medical device manufacturing.

Comparison of Plastic Rivets vs. Metal Fasteners

| Feature | Plastic Rivets | Metal Fasteners | Advantage | Disadvantage |

|---|---|---|---|---|

| Weight | Lightweight | Heavy | Reduces product weight | Lower strength |

| Cost | Low | High | Reduces production costs | Less durable |

| Environment | Recyclable | Non-recyclable | Environmentally friendly | Less eco-friendly |

| Corrosion | Strong | Prone to rust | Suitable for harsh environments | High maintenance cost |

Advantages of Replacing with Plastic Rivets

The advantages of replacing metal fasteners with plastic rivets are very clear, especially in large-scale production, which can effectively reduce overall costs. By using plastic rivets, manufacturers can reduce their dependence on metal materials, increase production efficiency, and lower production costs.

1.Lower production costs: Replacing metal rivets reduces raw material procurement costs.

2.Reduced weight: Reducing product weight: Plastic rivets can significantly reduce the weight of products, which aids in transportation and storage.

3.Improved environmental impact: Using plastic rivets aligns with environmental standards and reduces environmental burdens.

4.Improved corrosion resistance: Plastic rivets are more resistant to corrosion than metal rivets and perform well in harsh environments.

Conclusion

Plastic rivets not only have advantages in cost control but also demonstrate clear benefits in terms of environmental impact, lightweight properties, and corrosion resistance. With continuous advancements in manufacturing technology, the future applications of plastic rivets will be even broader. In the future, plastic rivets will undoubtedly become the preferred alternative material in many industries.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!