Introduction

The etching process is a key stage in mold surface treatment, where chemical corrosion or laser engraving creates unique textures on the mold surface. This surface treatment not only gives products a distinctive look but also improves anti-slip and wear resistance. In high-end injection-molded products, etching has become a fusion of design aesthetics and functionality.

As customer expectations for appearance and tactile quality rise, mold etching technology continues to evolve, achieving finer and more consistent results. It can hide machining marks while enhancing product value, making it an important advantage in plastic product competitiveness.

How does etching enhance the appearance and functionality of injection-molded parts?

Etching is not merely a method to beautify the surface; it also delivers significant functional benefits. By using textures of varying depths and shapes, it can alter the light reflection characteristics and improve grip. This technology can effectively reduce the visual impact of surface scratches.

- Improved Anti-Slip Performance: Textures increase friction and enhance grip comfort.

- Enhanced Wear Resistance: Surface structures slow down visible wear marks.

- Richer Visual Layers: Different texture combinations create a more premium appearance.

- Defect Concealment: Reduces the visibility of surface imperfections on injection-molded parts.

😊 Etching is both surface art and a key technique for functional optimization

What factors are most critical in the etching process?

The quality of etching is influenced by multiple factors, including the hardness of the mold steel, the complexity of the texture design, and the control of etching process parameters. Only when design, processing, and materials are precisely matched can stable etching results be achieved.

- Steel Hardness Matching: Suitable hardness ensures even etching.

- Accurate Texture Design: Design must account for plastic flow and draft angles.

- Strict Process Control: Temperature, time, and acid concentration must be precisely managed.

- Proper Surface Preparation: Polishing and cleaning ensure uniform etching.

🔍 Attention to detail is the core of high-quality etching

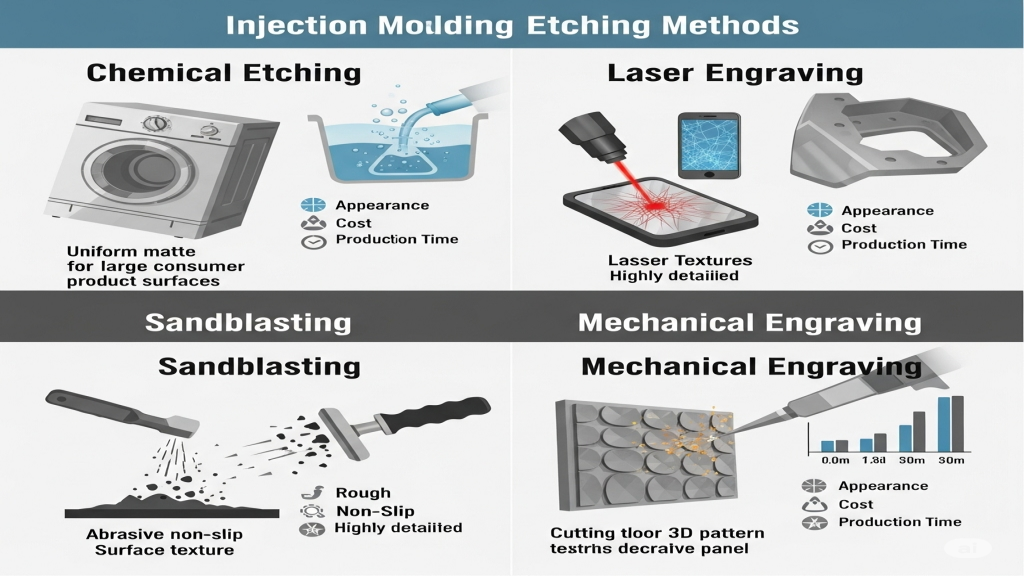

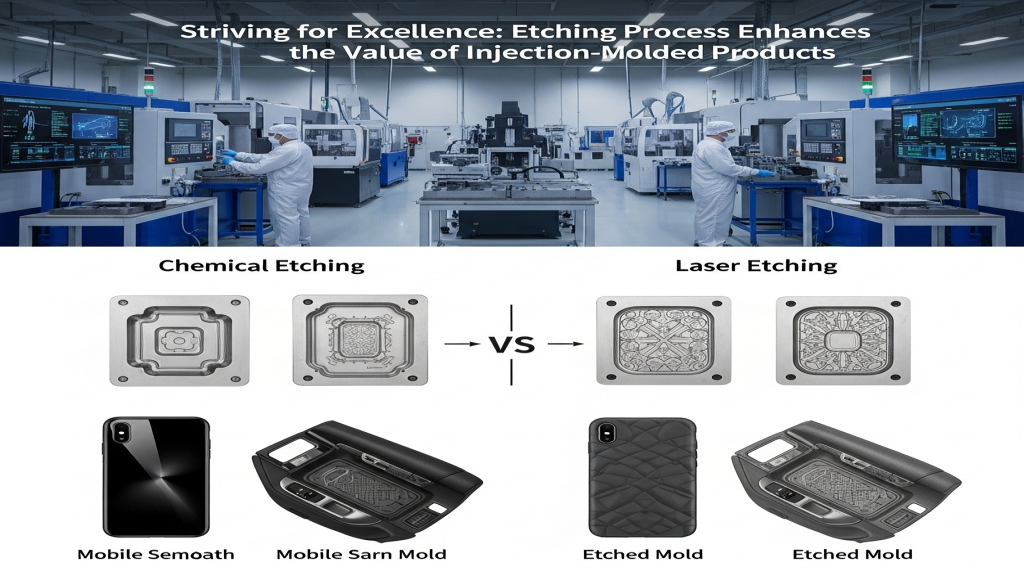

What are the differences between etching methods in injection production?

Etching methods vary, such as chemical etching, laser engraving, and sandblasting, each suited for different production requirements. Choosing the right process can strike the best balance between appearance, cost, and production time.

- Chemical Etching: Ideal for large areas with uniform texture.

- Laser Engraving: High precision for complex patterns.

- Sandblasting: Creates a distinct roughened surface.

- Mechanical Engraving: Depth control with strong 3D effects.

🎯 The choice of process determines the beauty and practicality of injection-molded parts

Comparison of Etching Process Types

| Process Type | Fineness | Cost | Lead Time | Durability |

|---|---|---|---|---|

| Chemical Etching | High | Medium | Medium | High |

| Laser Engraving | Very High | High | Medium | High |

| Sandblasting | Medium | Low | Short | Medium |

| Mechanical Engraving | High | High | Long | High |

How does etching affect mold maintenance and lifespan?

Etching changes the surface characteristics of molds, influencing cleaning and maintenance cycles. Fine etching requires more frequent maintenance to prevent residue buildup that may affect product quality. Considering ease of maintenance during design can help extend mold lifespan.

1.Increased Maintenance Frequency: Complex textures require more frequent cleaning.

2.Higher Corrosion Resistance Demand: Protective coatings extend service life.

3.Repair Difficulty: Deep textures require advanced restoration techniques.

4.Impact on Production Consistency: Worn textures may affect product uniformity.

Conclusion

Etching is not only a decorative surface technique but also a powerful way to enhance product value and competitiveness. In injection mold design and production, choosing the right etching method can balance aesthetics and functionality effectively. Looking ahead, with advances in materials and processing technologies, etching will deliver innovative appearance and tactile solutions to more industries.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!