Introduction

In injection molding, Melt Flow Index (MFI) is not a parameter to be overlooked. It directly reflects the fluidity of a material at processing temperatures and influences fill speed, demolding ease, and surface finish. Choosing the appropriate MFI is key to ensuring product performance and manufacturing efficiency.

MFI also plays a decisive role in the tolerance of processing windows. For multi-cavity molds or complex geometries, different MFI levels require different processing strategies. Ignoring MFI selection can result in defects like flow marks, short shots, or weld lines.

How does MFI affect structural integrity of molded parts?

High-MFI materials aid flow but usually have shorter polymer chains, resulting in lower strength and impact resistance compared to low-MFI counterparts. For parts requiring mechanical strength, low MFI materials are generally more reliable.

- Structural Support: Low-MFI resins perform better under load.

- Impact Resistance: High molecular weight enhances impact properties.

- Flow Optimization: High MFI is ideal for thin-wall molding.

- Dimensional Stability: High MFI can cause warpage or distortion.

😊 Select MFI wisely to balance strength and flowability.

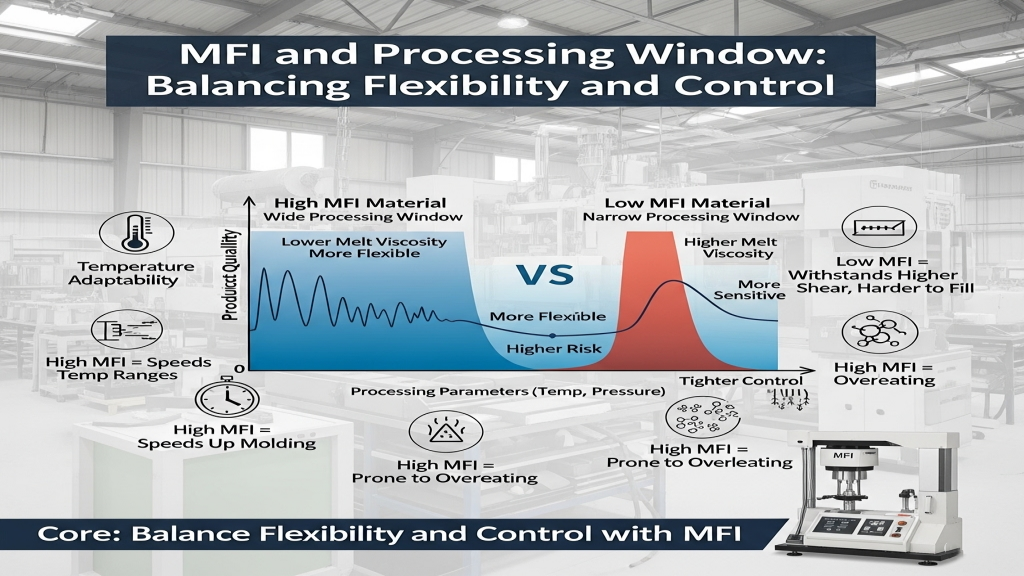

How do processing windows vary with different MFI levels?

Higher MFI means lower melt viscosity and a wider acceptable range for processing temperature and injection pressure. However, this also increases risks like flashing and thermal degradation. Lower MFI materials are more sensitive to processing settings and require tighter control.

- Temperature Adaptability: High-MFI resins tolerate wider temp ranges.

- Shear Resistance: Low-MFI can withstand higher shear but is harder to fill.

- Cycle Time: High-MFI materials speed up molding.

- Thermal Breakdown: High-MFI is prone to overheating issues.

🛠 MFI affects how flexible or narrow your process window is.

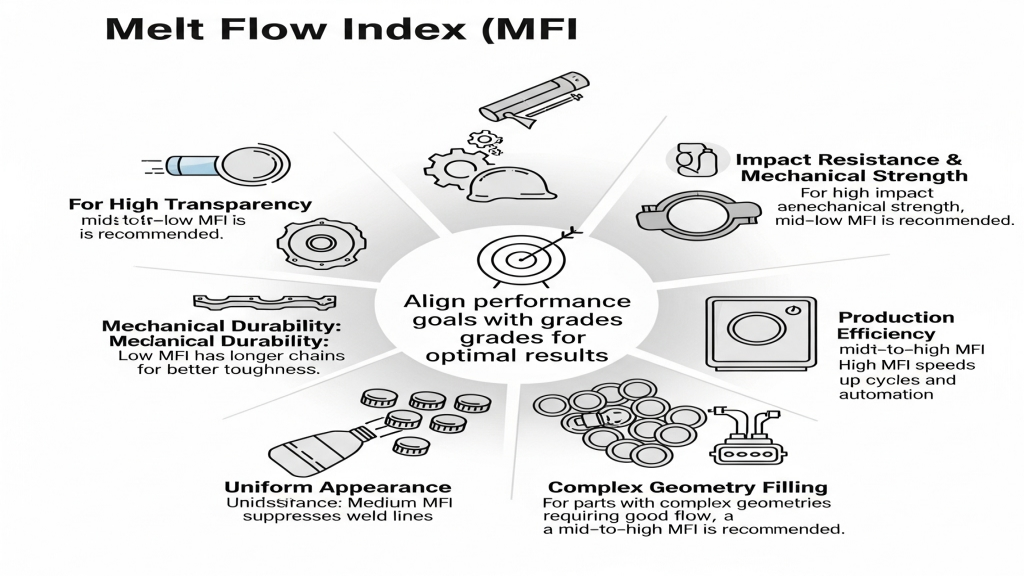

How should product performance requirements guide MFI selection?

For products needing high transparency, impact resistance, or mechanical strength, low to medium MFI materials are recommended. If fast cycle times or flowability in thin walls is a priority, medium to high MFI may be more suitable. Performance-oriented design must align with proper MFI level.

- Appearance Uniformity: Medium MFI suppresses weld lines.

- Mechanical Durability: Low MFI has longer chains for better toughness.

- Production Efficiency: High MFI speeds up cycles and automation.

- Complex Geometry Filling: High MFI helps fill intricate molds.

🔍 Align performance goals with MFI grade for optimal results.

MFI-Level Material Performance Comparison

| Property | High MFI | Medium MFI | Low MFI | Ultra-low MFI |

|---|---|---|---|---|

| Flowability | Excellent | Good | Moderate | Poor |

| Cycle Time | Fast | Moderate | Slightly slower | Slowest |

| Mechanical Strength | Moderate | Medium | High | Highest |

| Thin-wall Fillability | Excellent | Good | Moderate | Poor |

| Process Window | Wide | Fairly wide | Narrow | Very narrow |

| Defect Risk | High (flashing) | Moderate (weld) | Low (short shot) | Medium (voids) |

| Thermal Risk | High | Medium | Low | Low |

| Best For | Thin/High-speed | General parts | Structural parts | Industrial uses |

How to control MFI fluctuations through process?

Adjusting injection speed, back pressure, and mold temperature are key strategies to handle MFI variations. Even small differences between resin batches can be offset with optimal machine settings. Mold design should reserve flow compensation zones to tolerate batch MFI fluctuations.

1.Process Flexibility: Adjusting speed and pressure can offset shifts.

2.Runner Design: Balanced runner sizes reduce fill disparity.

3.Resin Traceability: Monitor MFI to prevent batch mixing.

4.Design Compensation: Thicker walls in flow-critical areas help.

Conclusion

Though a single index, MFI links to polymer weight, molding behavior, and final product performance. Understanding MFI isn’t just for material selection—it’s a compass for mold design and process optimization. Incorporating MFI early in the design phase prevents costly trial and error later.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!