Introduction

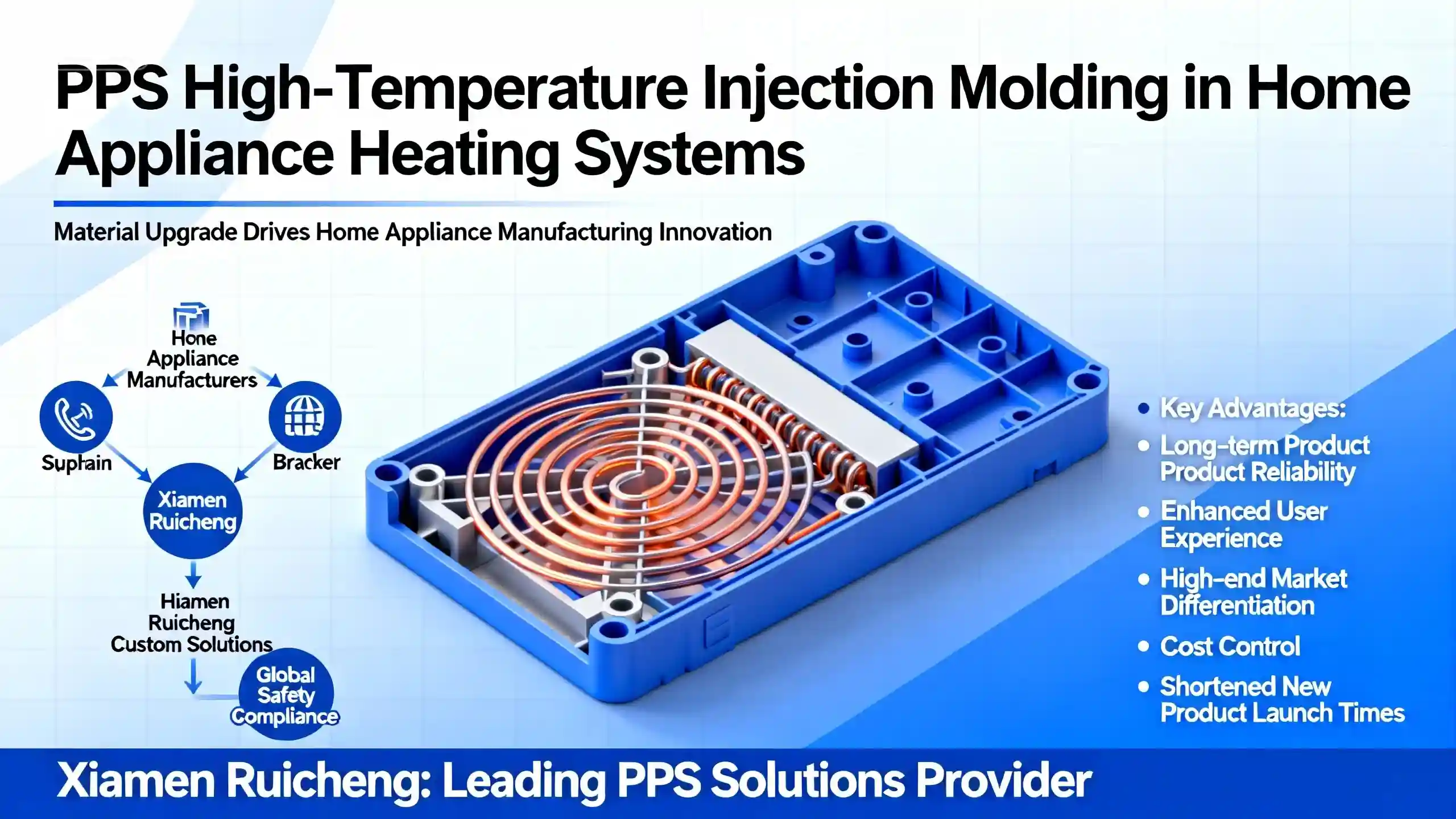

The bracket for the induction cooker heating coil is a core component for temperature control and structural support, and the heat resistance and insulation of its material directly affect the safety and service life of the entire appliance. Traditional materials are prone to deformation, decomposition, or even safety hazards under the high-frequency heating and localized high-temperature radiation environment of induction cookers, which has become a persistent core pain point for home appliance manufacturers. The adoption of PPS (Polyphenylene Sulfide) high-performance engineering plastic for high-temperature injection molding is emerging as the ideal solution to this challenge.

PPS material, with its outstanding high-temperature resistance, excellent dimensional stability, and high strength, maintains structural integrity and electrical insulation even under extreme thermal conditions. Professional injection molding manufacturers, such as Xiamen Ruicheng, ensure that every detail of the PPS bracket meets or even exceeds stringent home appliance safety standards through precise mold design and strict injection molding process control. This not only enhances product reliability but is also a strong testament to the home appliance brand's commitment to consumer safety.

How can the bracket material pass home appliance safety standards certification in a high-temperature environment?

When an induction cooker operates for an extended period, localized high temperatures are generated around the heating coil, imposing extremely stringent heat resistance requirements on the bracket material. This necessitates that the material possesses an extremely high Heat Deflection Temperature (HDT) and long-term thermal aging resistance to prevent structural failure or safety hazards caused by thermal stress. With a continuous use temperature exceeding 220°C, and an inherent flame retardancy rating of V-0, PPS material can easily withstand the instantaneous high-heat shock and long-term thermal load of induction cookers, fully meeting the stringent requirements of IEC, UL, and other international home appliance safety standards for temperature resistance and flame retardancy. Professional injection molding technology ensures no residual internal stress in the component, further enhancing its durability and stability under high temperatures.

Heat Deflection Temperature (HDT): PPS material effectively resists high-temperature intrusion in the core area of the induction cooker, ensuring the bracket structure does not soften or deform, thereby maintaining the precise positioning of the heating coil.

Flame Retardancy Performance: Its inherent high flame retardancy allows it to achieve the UL94 V-0 rating without the addition of excessive flame retardants, providing fire safety protection for appliances right from the material source.

Electrical Insulation: Even in high-temperature and high-humidity environments, PPS maintains stable, high dielectric strength, effectively isolating the heating coil from external circuits and preventing leakage risks.

Long-term Thermal Aging: Xiamen Ruicheng's PPS injection molded parts undergo strict thermal aging tests, proving that they can maintain critical mechanical and electrical properties throughout the induction cooker's designed lifespan.

😊 Choosing high-performance PPS material coupled with precision injection molding technology is the decisive factor for induction cooker brackets to pass home appliance high-temperature safety standards.

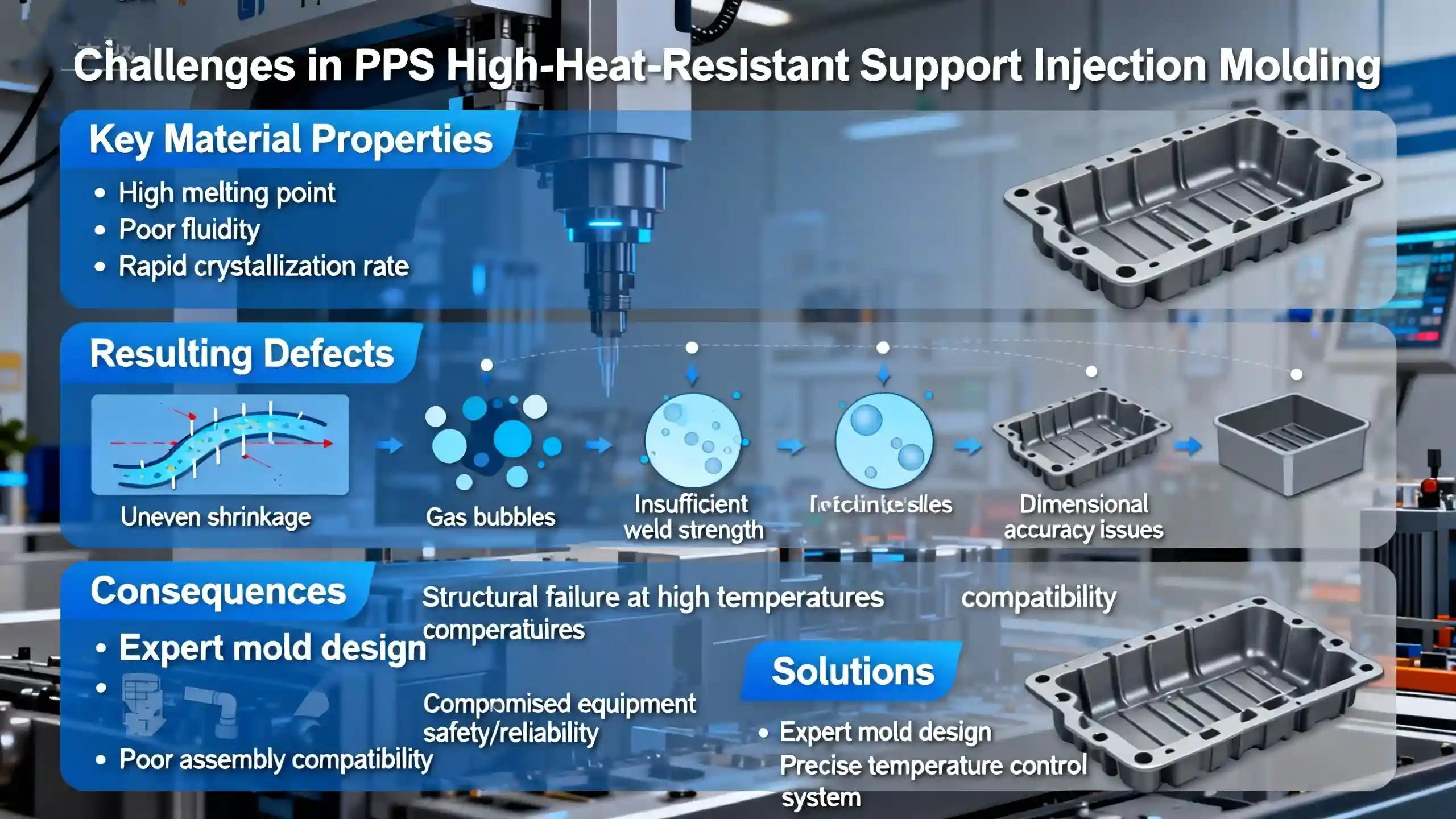

What are the core pain points faced by traditional injection molding processes in the production of PPS high-heat resistant brackets?

Despite the excellent performance of PPS as a high-performance engineering plastic, its injection molding requires extremely strict control over process parameters. Specifically, its high melting temperature, poor flowability, and rapid crystallization rate can easily lead to fatal defects such as uneven shrinkage, bubbles, insufficient weld line strength, or dimensional accuracy deviations. These defects, when present in an induction cooker bracket, can directly cause structural fracture or poor assembly under high temperatures, posing a serious threat to the safety and reliability of the appliance. Professional injection molding manufacturers must possess deep expertise in mold design and precise temperature control systems to overcome the challenges of high-temperature, high-pressure PPS processing and ensure the stability and consistency of product quality.

Mold Temperature Control Accuracy: PPS requires a very high mold temperature to ensure sufficient crystallization; even a slight deviation in temperature control can result in substandard product performance, affecting the bracket's high-temperature strength.

Weld Line Optimization: Induction cooker brackets often have complex structures, making weld line strength crucial. Precise control over runner design and injection pressure is necessary to avoid cracking under high temperatures.

Shrinkage and Warpage Control: PPS has a large crystallization shrinkage rate, and precision brackets demand high dimensional stability. This requires professional mold compensation and process parameter adjustment to precisely control tolerances.

Customized Material Selection: Different grades of PPS material must be accurately matched based on the varying requirements of induction cooker models for temperature resistance, strength, and color, ensuring the best balance of performance and cost.

🤔 The injection molding of PPS high-performance plastics poses extreme challenges to technology and equipment; even minor errors can lead to product defects that compromise appliance safety.

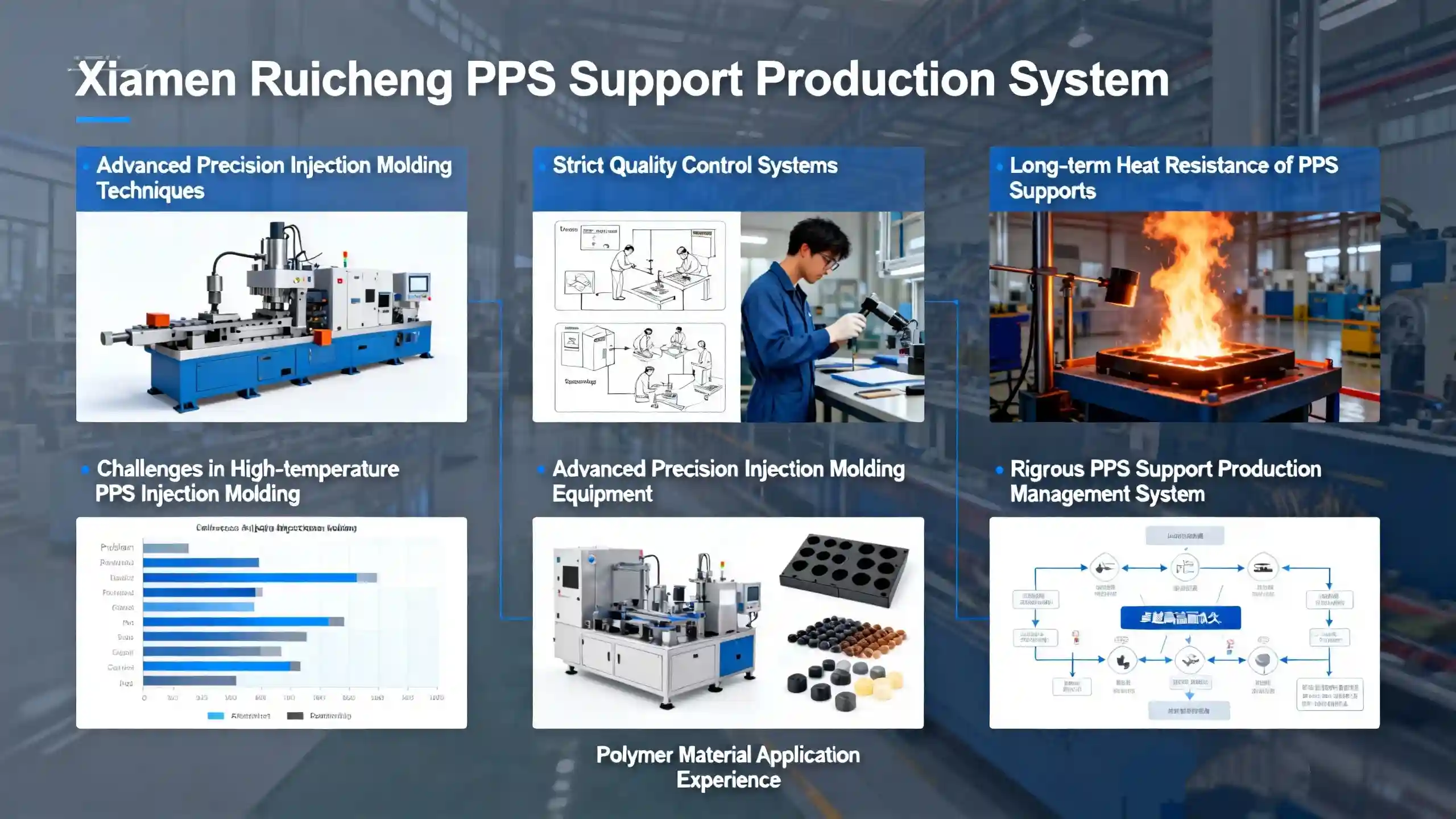

How does Xiamen Ruicheng ensure the long-term high-temperature reliability of PPS brackets through precision injection molding technology?

Xiamen Ruicheng is keenly aware of the difficulties in PPS high-temperature injection molding. By introducing advanced precision injection molding equipment and accumulating years of experience in polymer material application, they have established a rigorous and mature PPS bracket production management system, ensuring that every batch of products possesses exceptional high-temperature durability. From initial mold design, runner analysis, and cooling system optimization, to precise multi-stage temperature/pressure curve control during the injection process, and finally to comprehensive dimensional inspection and thermal shock testing before leaving the factory, every step aims to surpass home appliance safety standards. This full-link quality control effectively solves the industry pain points of poor dimensional stability and low weld line strength in PPS products, providing customers with truly reliable high-temperature structural component solutions.

DFM Feasibility Analysis: Intervention at the product design stage to evaluate the manufacturability of the bracket structure, preemptively eliminating potential injection molding defect risks, and ensuring a perfect match between design and process.

Mold Customization and Optimization: Utilizing high wear-resistant steel to customize high-precision molds, optimizing runner and venting systems to ensure uniform filling of the PPS melt, reducing stress concentration, and improving product yield.

Parameter Precision Control and Traceability: Employing fully automatic injection machines and real-time monitoring systems to precisely control injection speed, holding pressure, and mold temperature, with data-driven traceability of key parameters to guarantee batch consistency.

Thermal Shock and Durability Testing: In addition to conventional dimensional and appearance inspections, products undergo thermal shock and long-term high-temperature durability testing simulating induction cooker operating conditions, ensuring the long-term reliability of the bracket.

👍 Xiamen Ruicheng, through its precision injection molding technology and rigorous quality control system, provides customers with PPS high-temperature brackets that possess both high performance and high reliability.

PPS High-Temperature Injection Bracket vs. Traditional Materials

| Characteristic/Material | PPS (Polyphenylene Sulfide) Bracket | PBT Glass Fiber Reinforced | PET Glass Fiber Reinforced | Phenolic Resin (Thermoset) |

|---|---|---|---|---|

| Continuous Use Temperature | Above 220°C | 140-150°C | 160-180°C | 150-200°C |

| Flammability Rating (UL94) | V-0 (Inherent) | V-0 (Requires Additives) | V-0 (Requires Additives) | V-0 (Inherent) |

| Dimensional Stability | Excellent (Low creep at high temp) | General (Prone to deformation at high temp) | Better (Poor hydrolysis resistance) | Poor (Prone to brittle fracture) |

| Dielectric Properties | Excellent (Stable at high temp) | Good | Better | Good |

| Injection Molding Complexity | High (Requires precision temp control) | Low | Medium | Extremely High (Thermoset) |

| Mechanical Strength | Extremely High (High rigidity) | Higher | Higher | High |

| Applicable Appliance Standards | Easily Meets/Exceeds | Only for low-temperature zones | Only for medium-temperature zones | Applicable but complex process |

Are you looking for a solution that can completely resolve safety hazards associated with high-temperature brackets in induction cookers and guarantee consistency in batch supply? It's time to upgrade your critical component materials! Find out how Xiamen Ruicheng uses PPS precision injection molding to help you reduce appliance failure rates and enhance brand competitiveness. Contact us immediately at contact us.

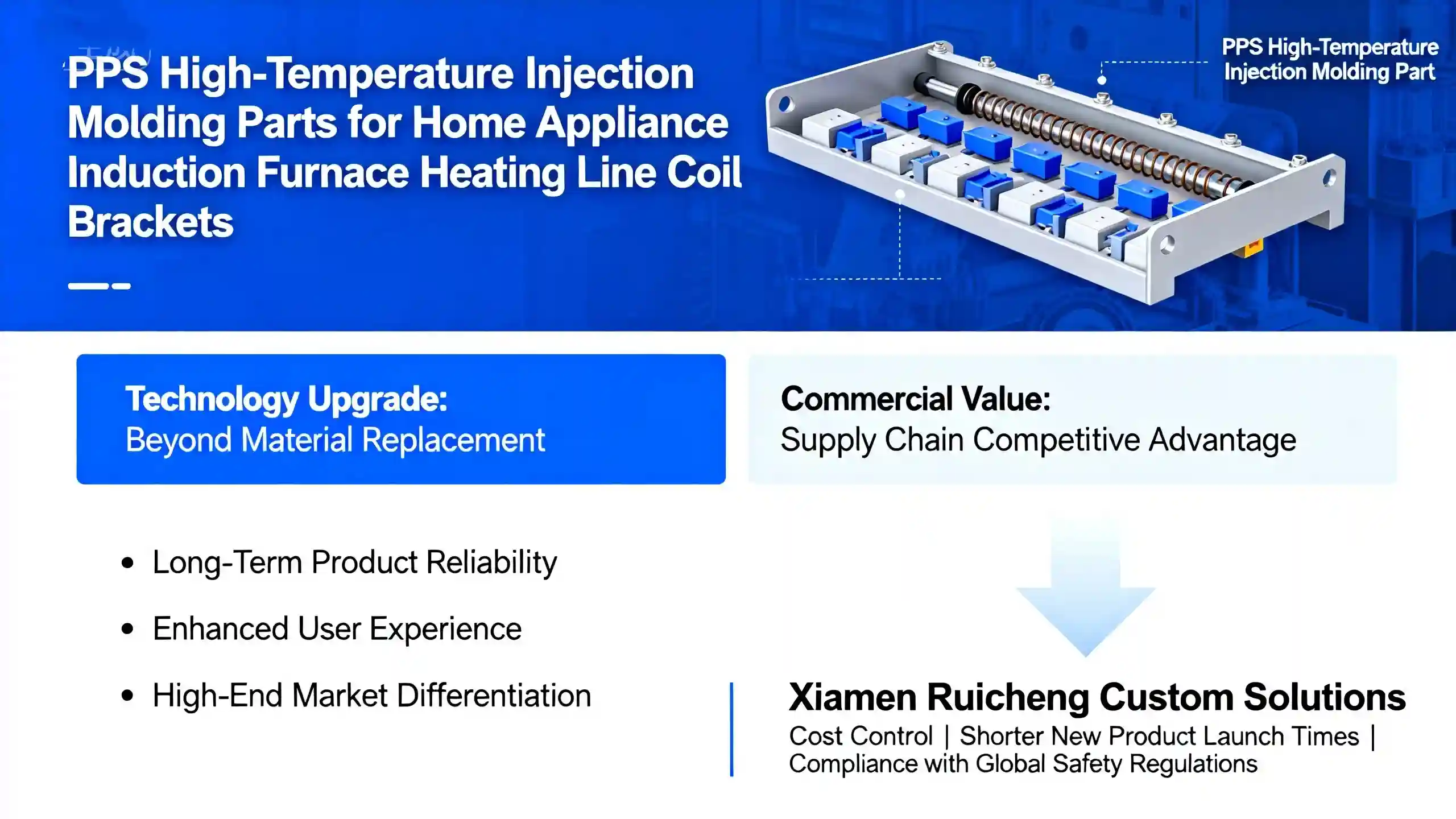

The Commercial Value of PPS High-Temperature Injection Brackets for the Home Appliance Industry

Adopting PPS high-temperature precision injection molded parts for the induction cooker heating coil bracket is more than just a material replacement; it represents a critical upgrade in home appliance manufacturing technology, bringing significant commercial value and competitive advantages to the entire supply chain. This performance leap directly translates into long-term product reliability, enhanced user experience, and differentiated positioning for the brand in the high-end market. Custom PPS solutions provided by professional injection molding manufacturers like Xiamen Ruicheng ensure that home appliance manufacturers can effectively control manufacturing costs and shorten the time-to-market for new products while meeting increasingly strict global safety regulations, achieving a commercial model shift from "parameter stacking" to "value empowerment."

1.Reduced Product Failure and Recall Risks:The stable performance of the PPS bracket under extreme high temperatures significantly reduces the failure rate of induction cookers caused by structural component thermal failure, effectively preventing costly product recalls and damage to brand reputation.

2.Accelerated Time-to-Market for High-End Products:Xiamen Ruicheng's rapid mold development and stable PPS injection capacity enable home appliance manufacturers to quickly transform innovative designs into marketable products, seizing the initiative in the high-end home appliance market.

3.Achieved Appliance Lightweighting and Miniaturization:PPS boasts an excellent strength-to-weight ratio, which aids in optimizing and lightweighting the internal structure of the induction cooker while ensuring structural support, meeting the modern appliance trend toward miniaturization and integration.

4.Improved Pass Rate for International Appliance Certifications:The inherent high heat resistance and flame retardancy of PPS material provide a strong guarantee for passing rigorous international home appliance safety certifications such as UL, IEC, and CE, clearing the path for global product sales.

FAQ

What are the core advantages/key metrics/quality standards of your PPS high-temperature injection brackets?

Answer: Xiamen Ruicheng's PPS high-temperature injection brackets offer the core advantage of material that can withstand continuous use temperatures up to 220°C and possess inherent UL94 V-0 flame retardancy. We utilize optical-grade precision injection equipment and in-line CCD visual inspection to ensure the bracket's dimensional accuracy tolerance is controlled within ±0.05mm, significantly exceeding industry standards, perfectly matching the ultra-high reliability requirements of high-end induction cookers for critical structural components.

We plan to procure PPS high-temperature injection brackets; what documentation/information is needed to quickly connect and receive a quotation?

Answer: To promptly respond to your needs, you only need to provide the product 3D model (STEP or IGS format), detailed 2D engineering drawings (marking critical tolerances and assembly requirements), and a preliminary estimate of the annual procurement volume. Please send the documents to our dedicated email, and we commit to initiating a design feasibility screening within 4 hours and providing a detailed quotation plan, including mold manufacturing and injection process analysis, within 24 hours.

Regarding PPS high-temperature injection brackets, what are the rules for minimum order quantity/delivery cycle/payment terms for different procurement volumes?

Answer: For new projects, we offer trial production support with a Minimum Order Quantity (MOQ) of 1000 pieces; bulk procurement of over 5000 pieces qualifies for a more favorable unit price. The standard injection part delivery cycle is 10-15 working days after order confirmation; we maintain flexible production lines, and urgent orders can be expedited through negotiation. Payment terms are flexible, supporting 30% deposit pre-payment + balance payment before shipment; long-term cooperative clients can negotiate monthly settlement.

If quality non-conformance/performance failure/delivery delay occurs after procuring PPS high-temperature injection brackets, how will your company handle it?

Answer: All delivered products are accompanied by batch quality inspection reports. If, within 15 days of arrival, issues such as dimensional deviation or performance non-conformance are confirmed through third-party or mutual reinspection to be caused by our production, we commit to initiating the free rework or return/replacement process within 72 hours. Critical performance is covered by a 2-year warranty period, and a formal agreement will specify strict compensation mechanisms for delivery delays to safeguard your interests.

Can your company provide customized adjustments/complement services for PPS high-temperature injection brackets based on our special working conditions/production needs?

Answer: Xiamen Ruicheng possesses strong customization capabilities and fully supports minor adjustments to the PPS material formulation or structural optimization based on your induction cooker's specific operating temperature, stress distribution, or special color requirements. You only need to provide detailed working condition parameter reports and environmental requirements, and our engineering team will provide a professional material and structural optimization proposal within 3 business days.

Conclusion

The use of PPS high-temperature injection molding for induction cooker heating coil brackets is not just a minimum requirement to meet home appliance safety standards, but a strategic choice for home appliance manufacturers pursuing excellence in high performance and high reliability. The superior heat resistance, high strength, and inherent flame retardant properties of PPS material, coupled with the rigorous process of Xiamen Ruicheng's precision injection molding, fundamentally solve the safety hazards and durability pain points of traditional materials in the high-temperature environment of induction cookers. Choosing a professional PPS precision injection molding partner means your home appliance products gain a longer lifespan and higher safety assurance, thereby establishing a more reliable brand image in the global market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!