Introduction

In the injection molding industry, homopolymer PP and random copolymer PP are widely used due to their performance differences. Selecting the right material not only affects product appearance but also determines durability and competitiveness. Accurate material selection directly reduces defect rates and production costs.

With diversified application demands, companies must evaluate properties such as heat resistance, transparency, and flexibility when developing new products. Only through scientific comparison can they maintain an advantage in a competitive market. Customized material selection is becoming a key trend in the injection molding industry.

In Which Applications Is Homopolymer PP More Suitable?

Homopolymer PP provides high stiffness and heat resistance, making it ideal for structural parts and heat-demanding applications. Its relatively low shrinkage rate enhances dimensional stability. In injection molding, homopolymer PP is often chosen for components that require high strength and durability.

- High rigidity use: Ideal for load-bearing and structural parts.

- Excellent heat resistance: Commonly used in automotive and electrical housings.

- Cost-effective option: Fits products with tight cost constraints.

- Dimensional stability: Suitable for products with strict tolerance requirements.

😊 Homopolymer PP emphasizes rigidity and heat resistance, ideal for functional applications.

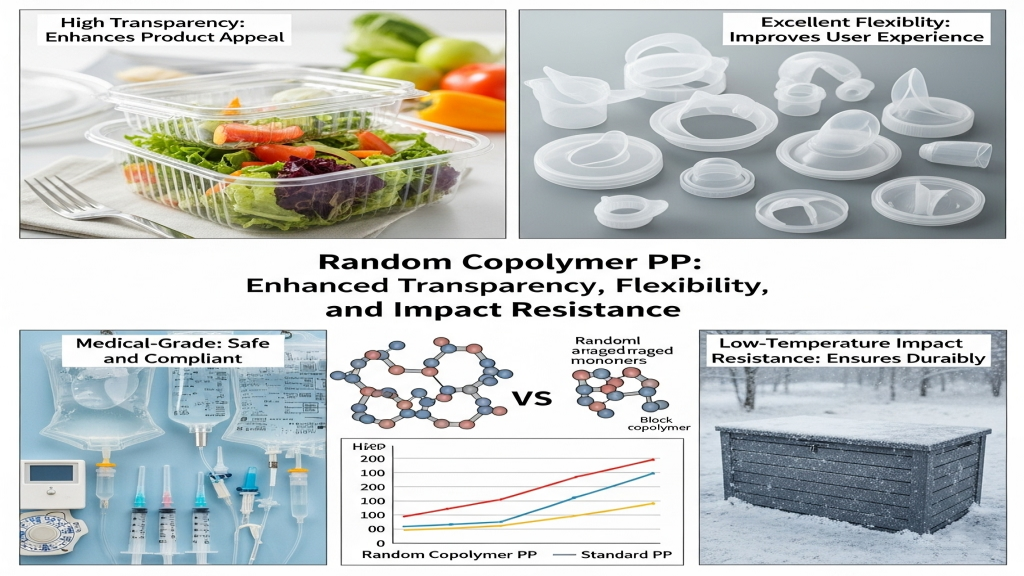

How Does Random Copolymer PP Enhance Product Performance?

Random copolymer PP offers superior transparency and flexibility, making it popular in household items and medical applications. It also maintains toughness at low temperatures, reducing the risk of brittle failure. For products requiring both appearance and flexibility, random copolymer PP provides greater advantages.

- High transparency: Perfect for light-transmitting applications.

- Excellent flexibility: Suitable for packaging and consumer goods.

- Low-temperature impact resistance: Ensures safety during use and transport.

- Medical-grade use: Meets hygiene and safety requirements.

✨ Random copolymer PP boosts appearance and flexibility, ideal for consumer products.

How to Balance Cost and Performance Between the Two PPs?

Balancing cost and performance is the core focus for manufacturers when selecting PP. While homopolymer PP is more economical, it falls short in transparency and flexibility. The optimal solution lies in aligning material choice with the product’s end-use requirements.

- Cost-driven choice: Homopolymer PP lowers production costs effectively.

- Performance-driven choice: Random copolymer PP fulfills flexibility and appearance needs.

- Dual applications: Composite solutions combine both materials for balance.

- Comprehensive evaluation: Consider lifecycle and environment before deciding.

💡 Balancing cost and performance is the key to precise PP selection in injection molding.

Homopolymer PP vs Random Copolymer PP

| Property | Homopolymer PP | Random Copolymer PP | Best Application | Cost Advantage |

|---|---|---|---|---|

| Rigidity | High | Medium | Structural parts | Homopolymer PP |

| Transparency | Moderate | High | Consumer & Medical | Random Copolymer PP |

| Heat Resistance | High | Medium | Automotive, Electrical | Homopolymer PP |

| Flexibility | Moderate | High | Packaging, Containers | Random Copolymer PP |

How to Optimize PP Performance Through Injection Molding?

【Image】

Different injection molding conditions can enhance or weaken the performance of PP. Proper control of mold temperature, holding pressure, and cooling can improve dimensional accuracy and product quality. Optimized processing maximizes the advantages of PP materials.

1.Mold temperature control: Higher mold temperatures improve crystallinity of homopolymer PP.

2.Holding pressure setting: Prevents shrinkage and warpage.

3.Balanced cooling: Enhances transparency and precision.

4.Flow channel design: Reduces weld lines and material waste.

Conclusion

Choosing between homopolymer PP and random copolymer PP reflects not only performance considerations but also market positioning. A scientific material selection strategy can strengthen competitiveness while lowering overall costs. By combining injection molding optimization, products can achieve a balance of rigidity, transparency, and flexibility. Continuous exploration in material applications ensures long-term advantages in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!