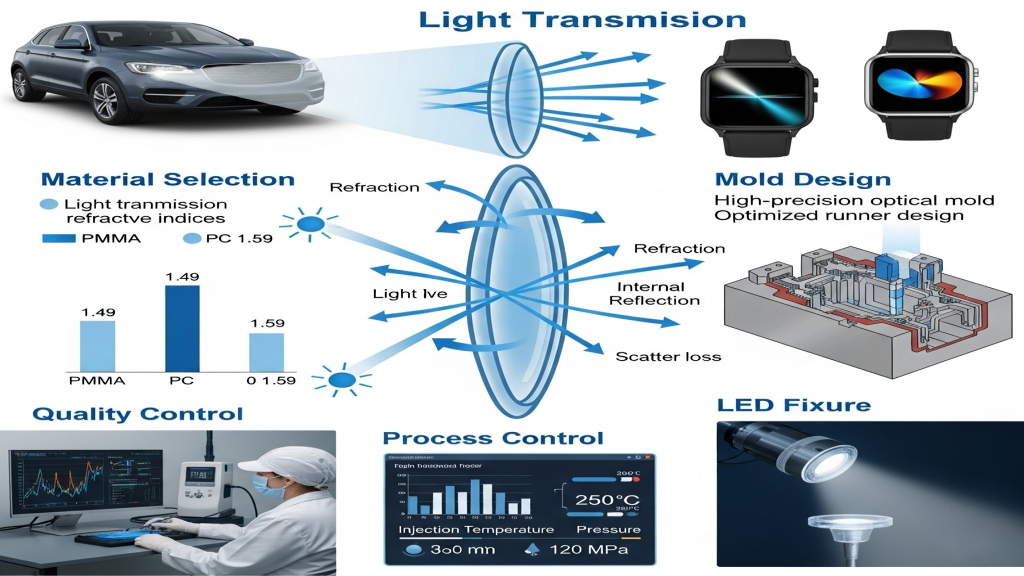

Basics of Light Transmission

Light transmission is a core performance indicator for optical injection molded parts, relying heavily on high-transparency materials and precise mold processing. By strictly controlling material selection, runner design, and process parameters, the light transmission efficiency can be significantly improved.Carefully engineered processes form the foundation for effective light conduction.

Additionally, growing demand for automotive lighting, wearable tech, and LED optics is raising the bar for flawless, transparent molded parts. Only companies that continuously improve their optical molding process can gain customer trust and market share.Optical-grade injection molding is now essential for premium product manufacturing.

How Does Material Choice Affect Light Transmission?

Selecting the right optical material is critical to improving the light-conducting ability of molded parts. Differences in refractive index, light transmittance, and heat resistance directly determine performance.High light transmittance and low scattering are core selection criteria.

- PMMA Advantages: Offers excellent clarity and smooth molding.

- PC for Impact-Optical Balance: Combines optical clarity with toughness.

- Cyclic Olefin Polymer (COP): Emerging choice for advanced optical components.

- TPE/TPU in Flexible Optics: Suitable for light strips and diffusers.

🔍 High transparency materials are the starting line for optical performance.

Which Injection Molding Steps Disrupt Light Paths Most?

From runner design and gate location to cooling rate, each step can introduce stress, haze, or refractive distortions that affect the integrity of the light path.Cavity geometry and injection balance determine how smoothly light travels through the part.

- Precision Gate Design: Controls surface stress points.

- Sensitive Mold Temperature Tuning: Reduces internal stress formation.

- Slow Fill and Hold Pressure: Prevents bubbles and streaks.

- Accurate Draft Angles: Avoids warping or scratching of optical surfaces.

💡 Every detail in injection molding protects the purity of light flow.

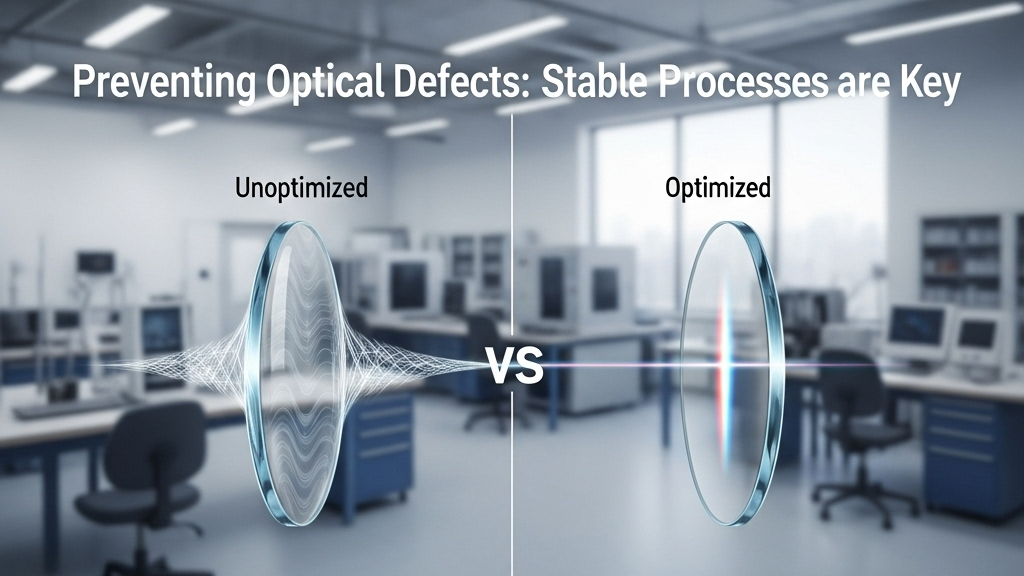

How to Prevent Optical Defects and Deformation Post-Molding?

Residual stress, uneven cooling, or poor venting can cause light distortion and blurriness. Solutions go beyond post-processing and begin with mold design.Surface waviness, micro-deformations, and stress buildup are the silent enemies of optical clarity.

- Synchronized Mold Temp Control: Prevents cold-spot stress zones.

- Balanced Dual-Cavity Cooling: Reduces warpage risk.

- UV Hard Coating: Enhances scratch resistance and clarity.

- Precision Optical Testing: Ensures batch consistency and accuracy.

🔧 Stable and controlled processes prevent unwanted distortion.

Optical Material Processing Comparison Table

| Material | Light Transmittance (%) | Refractive Index | Molding Temp (℃) | Impact Resistance | Cost Level | HDT (℃) | Applications |

|---|---|---|---|---|---|---|---|

| PMMA | 92–93 | 1.49 | 220–250 | Low | Medium | 85–95 | Light covers, panels |

| PC | 88–90 | 1.58 | 260–310 | High | Med-High | 125–135 | Lenses, headlights |

| COP | 91–94 | 1.53 | 230–260 | Medium | High | 130–140 | Optical devices |

| TPU/TPE | 85–88 | 1.47 | 190–210 | Medium | Medium | 60–80 | Light strips |

How Does Precision Molding Enhance Optical Output?

In optical molding, precision directly affects light uniformity and transmission efficiency. Even micron-level errors or asymmetries can scatter light and reduce output.Accurate processing not only boosts performance but represents premium product quality.

1.High-Precision CNC Tooling: Reduces surface flaws and improves clarity.

2.Micro-Polished Mirror Molds: Achieves uniform planar diffusion.

3.IML + In-Mold Coating: Integrates visual and optical functions.

4.Closed-Loop Digital Control: Improves mass production repeatability.

Conclusion

The key to optical injection molding lies in tight control over materials, processing routes, and molding precision. Each optimization step drives performance improvements.High-efficiency light-transmitting parts require scientific, system-based molding workflows, fulfilling growing demands in smart lighting and wearable tech. Manufacturers must speak the language of engineering to stay ahead in competitive markets.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!