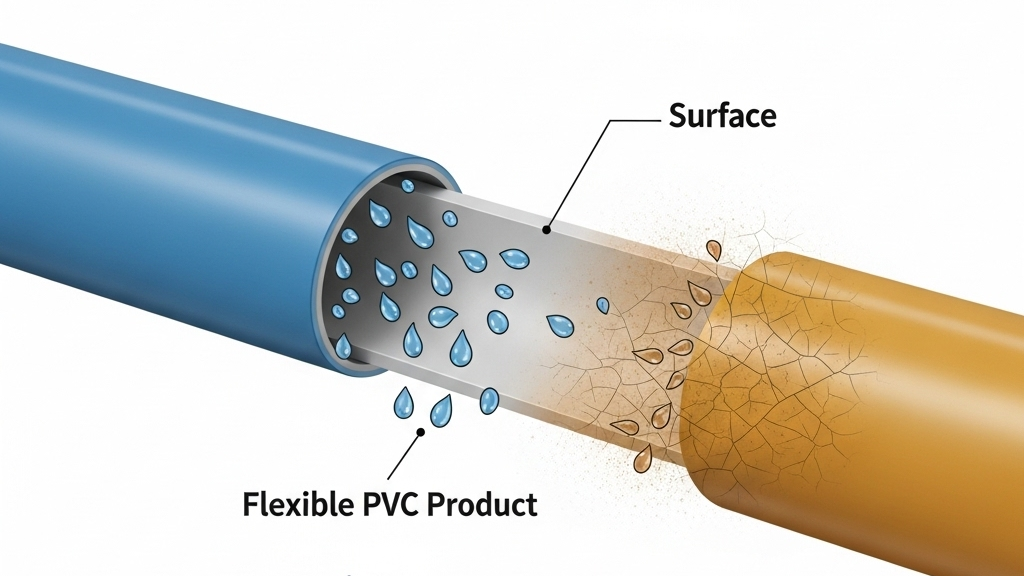

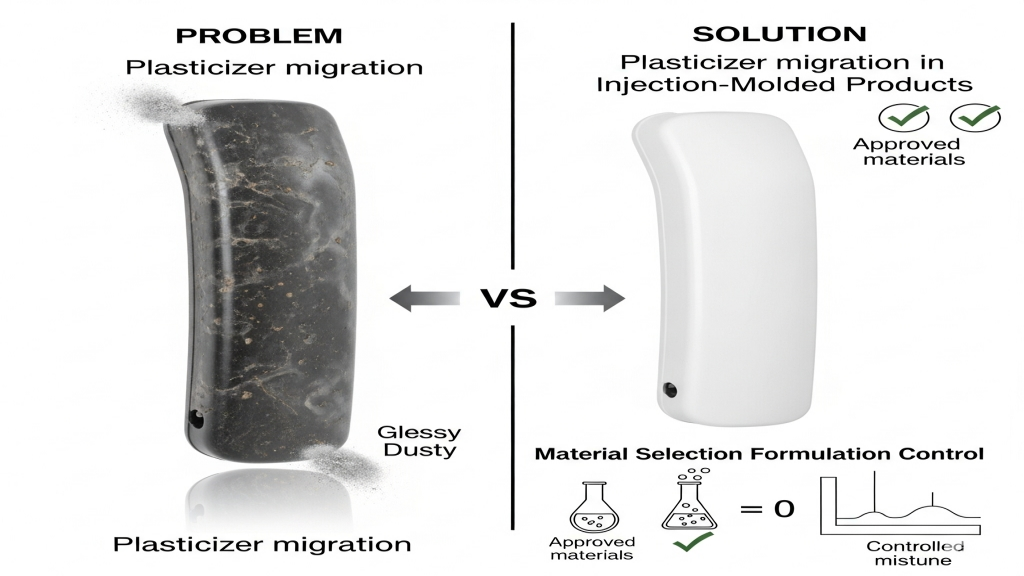

Plasticizers are widely used in injection molded products to enhance flexibility, but their potential to migrate over time poses risks to product performance and environmental safety. The greasy surface and dust adhesion often seen on plastics are typical signs of plasticizer migration. This impacts not only appearance but also functional lifespan.

To reduce migration, manufacturers must carefully control raw material selection, formulation design, and processing conditions. Choosing highly compatible plasticizers and maintaining proper ratios are critical to ensuring stability.

What Are the Main Causes of Plasticizer Migration?

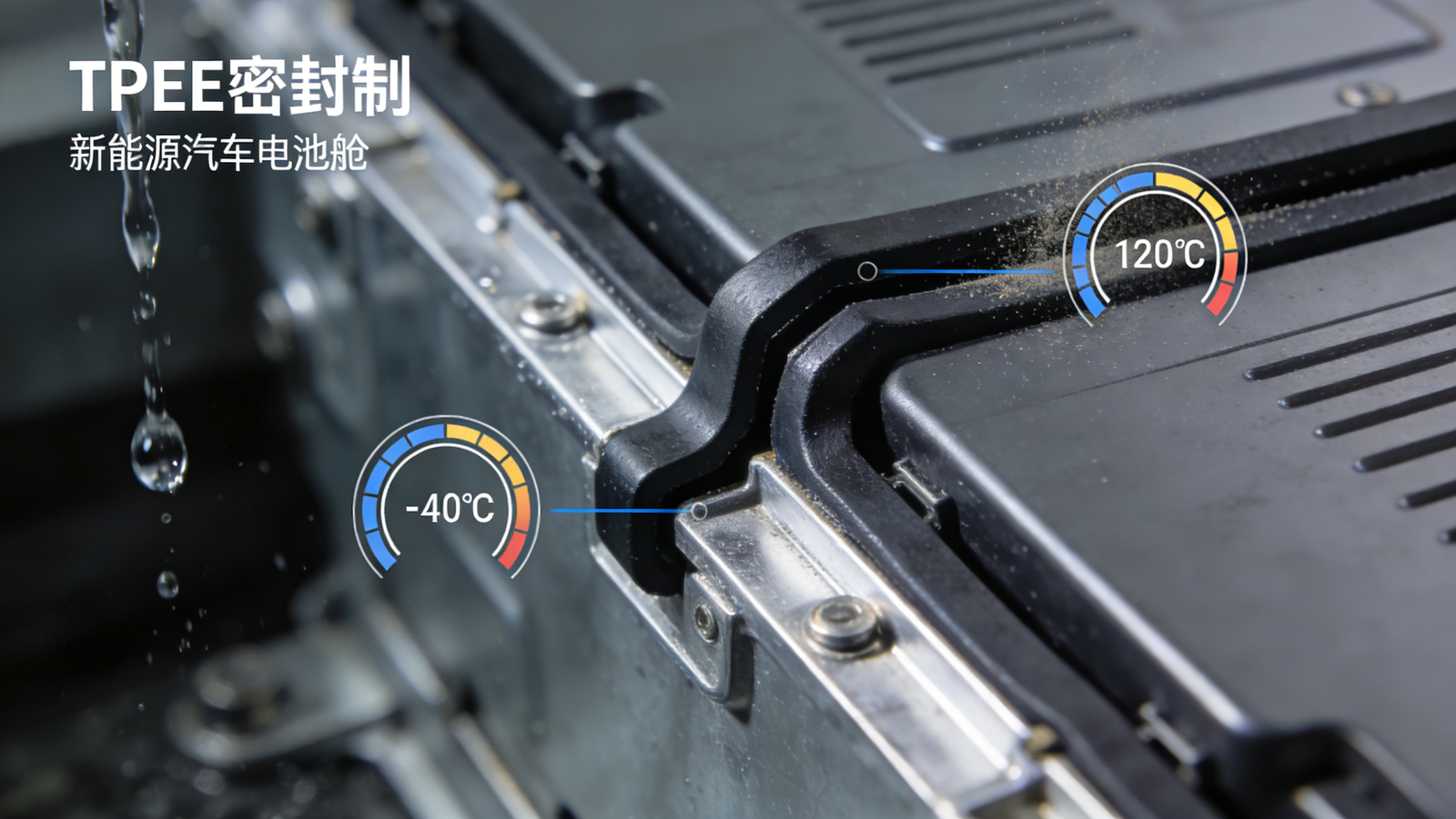

During injection molding, plasticizers with poor compatibility or insufficient bonding to base polymers tend to migrate to the surface. This is especially intensified in high-temperature or humid environments, causing visible exudation.

- Low molecular weight plasticizers: More likely to migrate at elevated temperatures.

- Poor formulation compatibility: Weak intermolecular forces between base resin and plasticizer.

- Excessive processing temperatures: Can degrade molecules and release migrating compounds.

- Loose surface structure: Promotes paths for migration accumulation.

Which Material Combinations Help Reduce Migration?

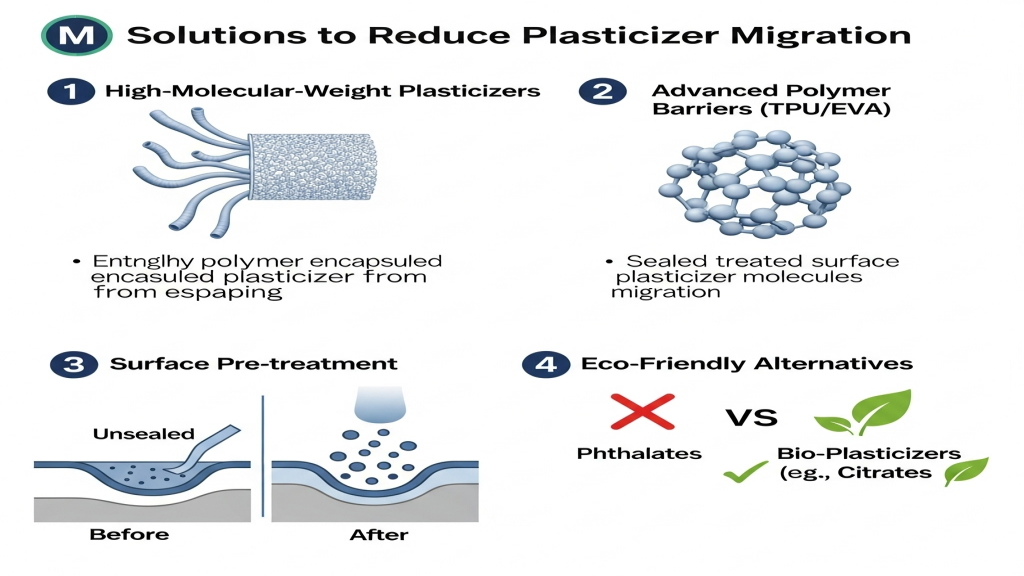

High molecular weight plasticizers with stable chain structures are more compatible with substrates like PVC and TPU. Using low-migration plasticizers forms the basis for performance stability.

- Use polyester-based plasticizers: Long chains and polar structures limit migration.

- Pair with advanced polymers: Materials like TPU or EVA show better encapsulation behavior.

- Surface pretreatment: Improves bonding and interface stability.

- Avoid phthalate-based plasticizers: High migration even at ambient conditions.

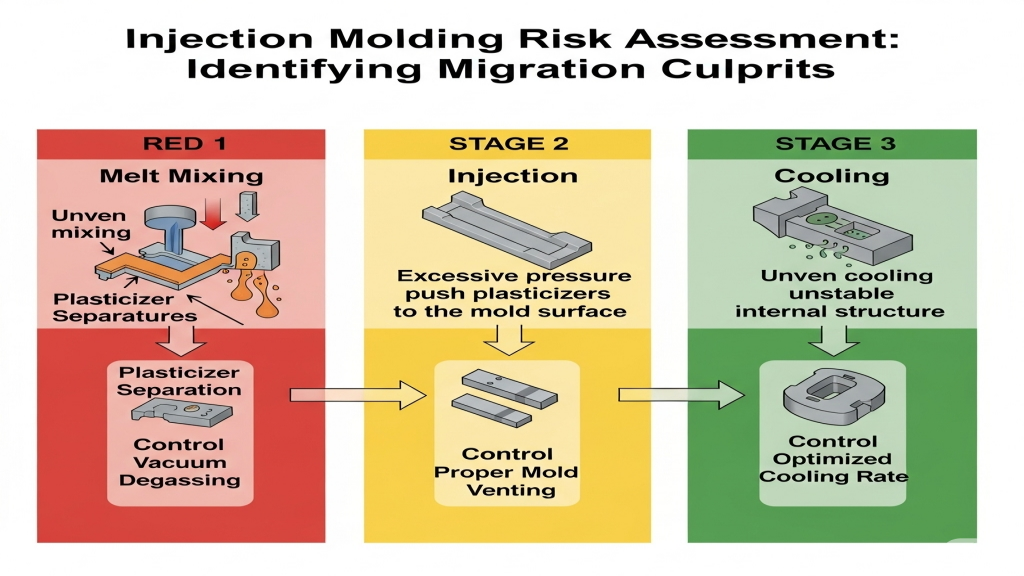

Which Injection Molding Stages Increase Migration Risks?

From melt mixing and injection to cooling, each phase can impact plasticizer stability. Inconsistent cooling or excessive mold release agents can significantly accelerate migration.

- Optimize cooling rate: Helps stabilize internal structures quickly.

- Precise temperature control: Prevents molecular separation of plasticizers.

- Use vacuum degassing: Removes unbound volatiles effectively.

- Improve mold venting: Reduces localized accumulation of migratory residues.

Plasticizer Compatibility Comparison

| Plasticizer Type | Compatibility | Migration Risk | Heat Resistance | Cost | Suitable Materials | Eco-Friendliness | Processing Difficulty |

|---|---|---|---|---|---|---|---|

| DOP | Medium | High | Average | Low | PVC | Poor | Easy |

| DOTP | High | Medium | Good | Medium | PVC/TPU | Fair | Medium |

| Polyester-based | High | Low | Good | High | TPU/EVA | Good | Difficult |

| Epoxidized Soybean Oil | Medium | Low | Average | Medium | PVC | Excellent | Medium |

How to Prevent Migration from the Source?

To prevent migration, formulation, interface sealing, and additive stability must be addressed holistically. Restricting the mobility of plasticizer molecules and blocking migration channels is essential in early design.

1.Optimize molecular structure: Use larger plasticizers with lower diffusion.

2.Reinforce interface sealing: Blending or encapsulation to reduce exposure.

3.Incorporate anti-migration agents: Enhance thermal and structural stability.

4.Precise thermal control: Ensures energy balance and containment.

Conclusion

Mitigating plasticizer migration demands a full-chain design approach covering materials, formulas, and processing controls. Focusing on structural stability and interface control is key to achieving low-migration performance. Manufacturers should prioritize eco-friendly, high-MW plasticizers and integrate optimized processing to ensure long-term durability and market competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!