The pet economy is booming, and the pet supplies market is growing rapidly with increasingly diverse and functional products. The flexibility and cost-effectiveness of PVC in injection molding have made it a preferred material for pet products.

PVC’s application in injection-molded pet supplies has become a mainstream trend.

With rising consumer expectations for safety, aesthetics, and customization in pet products, PVC’s stability and plasticity help it stand out in the market. Businesses that seize this trend and respond quickly to custom demands can gain a significant competitive edge.Customized demand continues to drive growth in injection-molded PVC products.

Why is Injection-Molded PVC Ideal for Pet Products?

PVC material offers great flexibility, waterproofing, and abrasion resistance, making it ideal for pet toys, feeders, and beds. Its high plasticity during processing enables innovative designs.

- Flexibility Advantage: Excellent chew resistance and safety for pets.

- High Molding Efficiency: Suited for mass production and standardized processing.

- Wide Design Scope: Complex shapes and multifunctional designs are easily realized.

- Safe & Eco-Friendly: Food-grade PVC ensures safety for pet usage.

What Drives the Rising Demand in the Market?

Pet owners demand better looks, textures, and functionality, positioning PVC as a material that meets these standards. Mid-to-high-end products are key application areas for injection-molded PVC.

- Customization Trends: Consumers prefer unique shapes and personalized colors.

- Quality Upgrade: Premium PVC products are replacing low-grade alternatives.

- Faster Product Iteration: PVC molding supports rapid product rollouts.

- Brand Value Boost: High-touch, stylish designs enhance product value.

How Can Businesses Use PVC to Break Through?

With an evolving consumer market, companies can introduce high-performance PVC injection solutions to boost value and efficiency. Deep integration of PVC material and injection technology unlocks new competitive advantages.

- Smart Manufacturing: Automated injection systems reduce labor costs and improve productivity.

- High-Speed Updates: Keep pace with market trends and shorten product development cycles.

- Market Expansion: Custom offerings reach broader consumer segments.

- Co-Branding Opportunities: IP collaboration increases brand reach and appeal.

PVC Product Applications

| Product Type | Material Stability | Molding Flexibility | Cost Control | Market Feedback | Sustainability | Safety Standard | Design Compatibility |

|---|---|---|---|---|---|---|---|

| Pet Toys | High | High | Medium | Excellent | Medium | High | High |

| Pet Feeders | Medium | Medium | High | Excellent | High | High | Medium |

| Pet Beds | High | High | Medium | Moderate | Medium | Medium | High |

| Cleaning Tools | Medium | Medium | High | Moderate | High | High | Medium |

What Other Opportunities Exist for PVC?

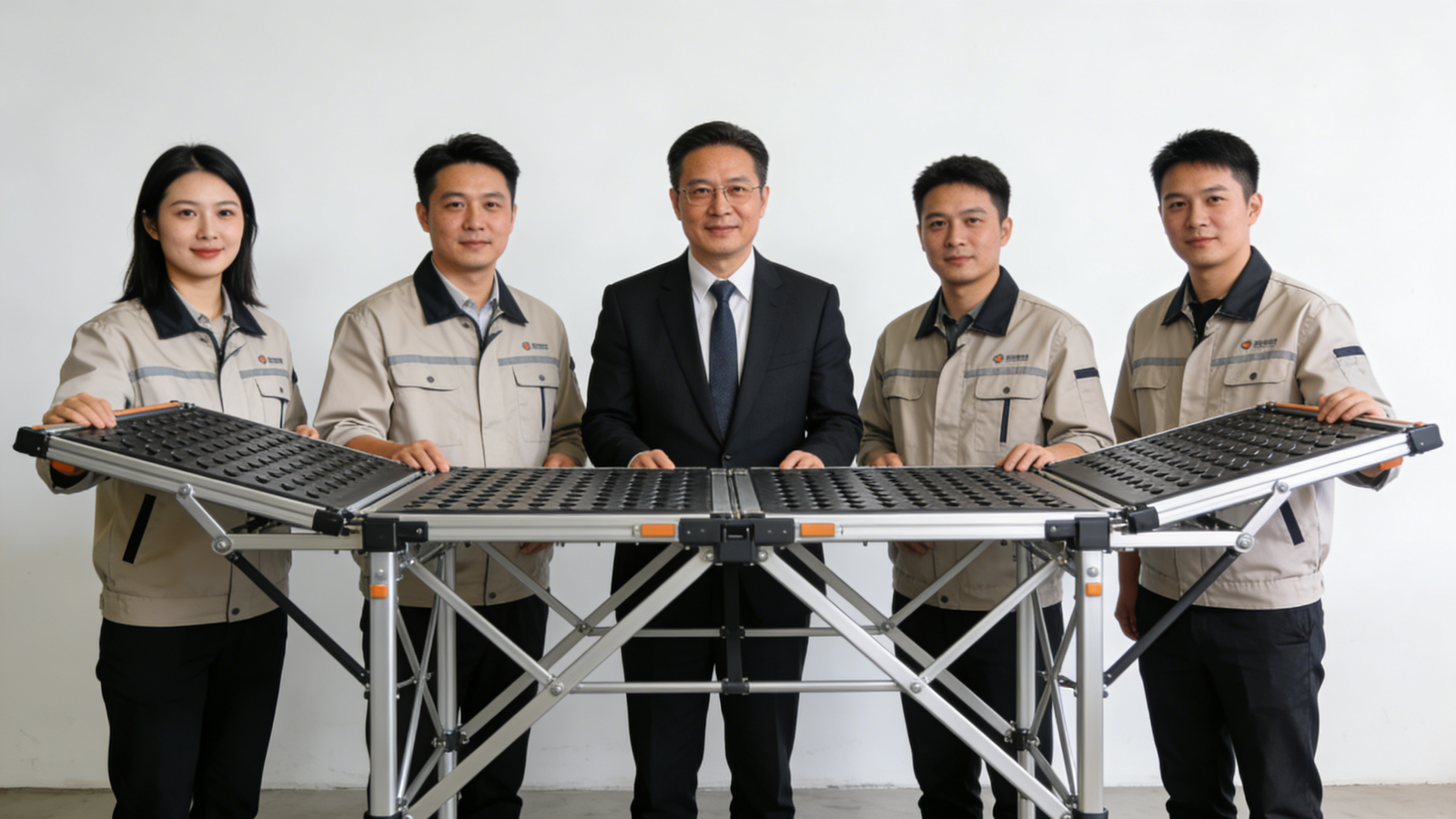

![Image]

Beyond traditional items, PVC is expanding into wearable and smart pet devices, balancing comfort and innovation. Its post-processing adaptability enables more functional applications.

1.Wearable Products: Like GPS collars or health monitor casings.

2.Interactive Smart Toys: More complex mechanics need versatile materials.

3.Co-Branding Hot Items: Supports collaborative IP product lines.

4.Eco-Friendly Path: Bio-based PVC options support sustainable development.

Conclusion

With excellent processing performance and material properties, injection-molded PVC is rapidly gaining traction in the pet supplies industry, particularly in premium markets. As consumer expectations evolve, The market adaptability of PVC injection products will be a key factor in future supply chain strategies.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!