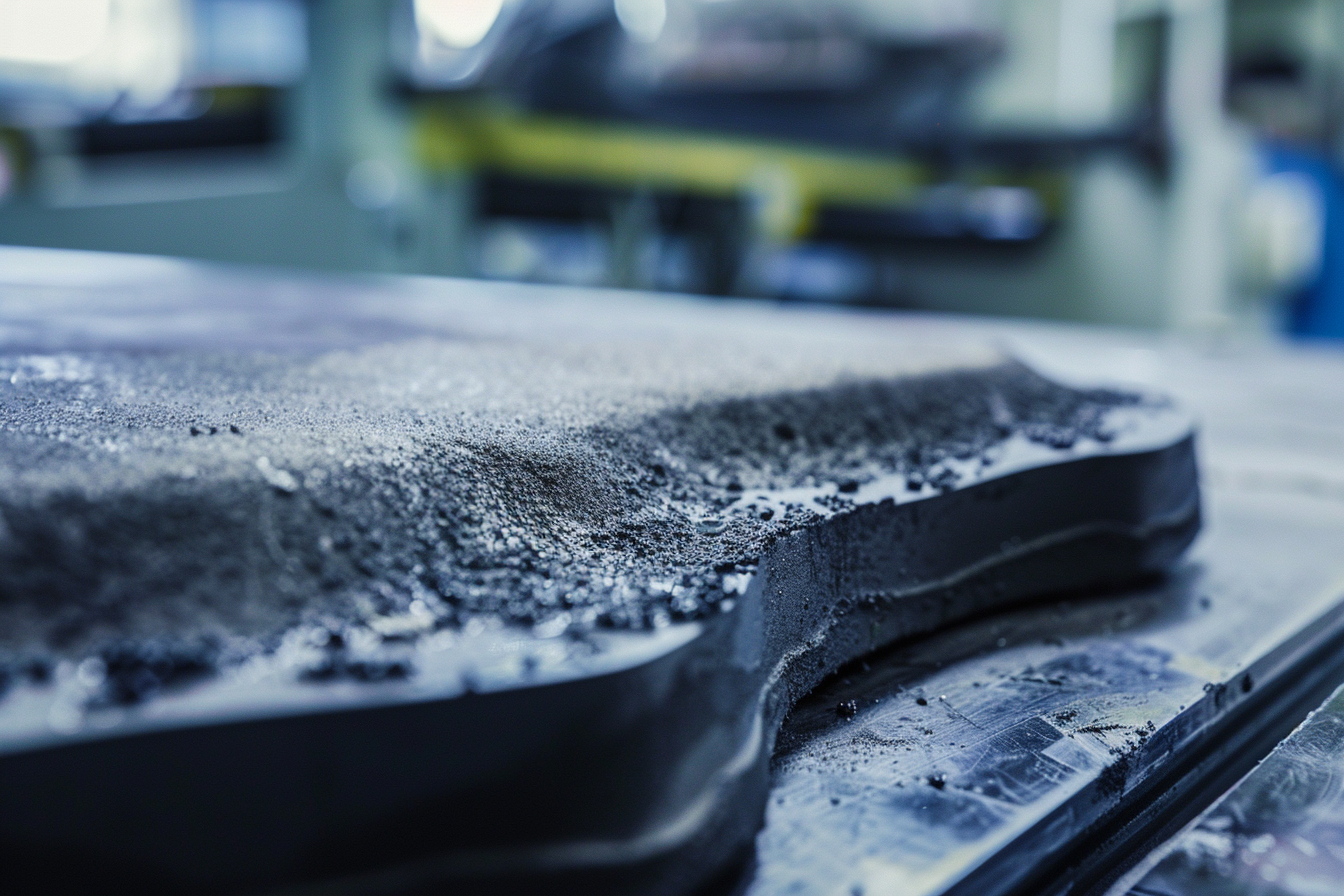

Shrinkage in thick ABS parts is primarily caused by uneven cooling. When the surface cools faster than the core, internal stresses develop, pulling the material inward and leading to dimensional changes. This effect is more pronounced in thicker sections, where the difference in cooling rates creates an imbalance.

But what exactly makes shrinkage such a common issue in thick ABS parts? Let’s dig into why it happens and what’s really going on beneath the surface.

What factors increase shrinkage risk in thick ABS parts?

When I first encountered shrinkage issues, I felt like I was chasing a ghost—couldn't see it, but it was definitely messing things up.

Shrinkage in thick ABS parts is influenced by multiple factors, including part geometry, wall thickness variations, and processing conditions. These variables create challenges that lead to greater shrinkage and dimensional instability.

One of the biggest culprits in shrinkage issues is part geometry. Complex shapes or areas with varying wall thickness can create stress points, where certain sections of the part are more prone to pulling inward during cooling. For example, parts with sharp corners or large flat sections often experience more pronounced shrinkage, especially if the wall thickness is inconsistent.

These stress points contribute to warping or dimensional inconsistencies, which can be a major problem in industries that demand precision, such as automotive or electronics. Parts designed with complex geometries often require careful planning to balance these areas and reduce shrinkage risk.

To counter these issues, thoughtful design strategies can help. For instance, minimizing sudden changes in wall thickness and incorporating rounded edges instead of sharp corners can go a long way in reducing stress points. By addressing these design factors early, you set the stage for better results in managing shrinkage throughout the process.

How can controlling the cooling rate help?

I like to think of controlling the cooling rate as the Goldilocks principle—not too fast, not too slow, but just right.

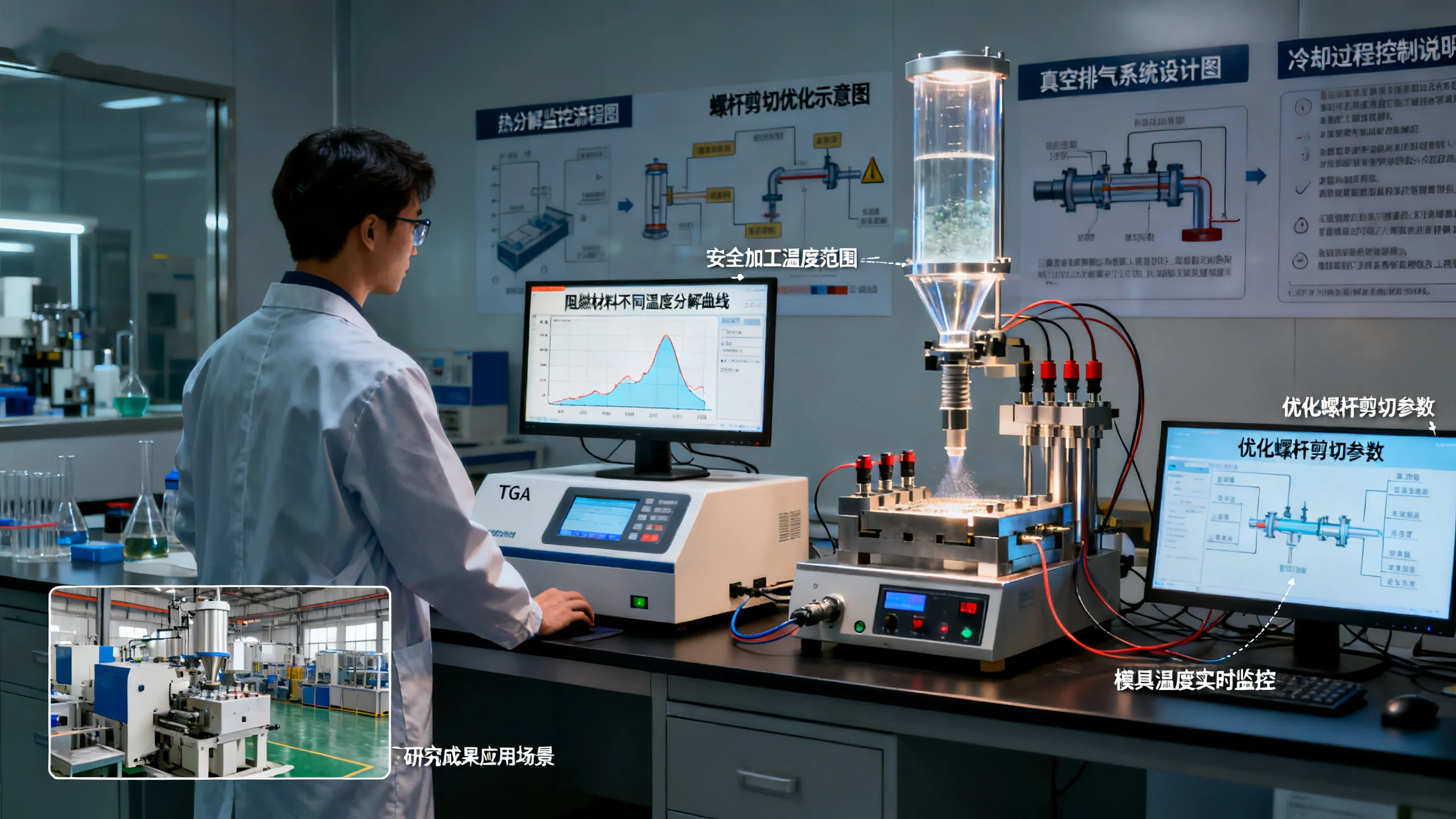

By managing the cooling rate, you allow the ABS material to solidify uniformly, reducing internal stresses and minimizing shrinkage. This involves optimizing mold temperatures and cooling times during the injection molding process.

Controlling the cooling rate is all about balance. If the mold is too cold, the outer layers of the ABS will solidify too quickly, trapping heat in the core. This leads to those pesky internal stresses. On the other hand, if the mold is too hot, the entire part takes longer to cool, slowing down production and potentially affecting the material properties.

One technique I've found effective is using conformal cooling channels. These are cooling channels that closely follow the geometry of the part, ensuring even cooling throughout. This can significantly reduce cooling times and improve part quality.

Another strategy is to adjust the mold temperature settin. By setting the mold temperature slightly higher for thick parts, you allow the material to cool more evenly. It's a bit like preheating your oven to the right temperature to bake that perfect loaf of bread.

Additionally, using materials with better thermal conductivity for the mold can help distribute heat more evenly. Copper alloys, for example, can be used in critical areas to improve cooling efficiency.

What role does material selection play?

Picking the right material is like choosing the right tool for a job—it makes everything smoother.

Selecting ABS materials with lower shrinkage rates or using additives can significantly reduce shrinkage in thick parts. Materials with higher viscosity can help maintain dimensional stability during cooling.

Not all ABS materials are created equal. Some grades are specifically designed to have lower shrinkage rates. For instance, glass-filled ABS contains glass fibers that reduce the material's tendency to shrink. These fibers act as a reinforcing agent, providing dimensional stability.

However, adding fillers like glass fibers can affect other material properties such as impact strength and surface finish. It's essential to weigh these trade-offs based on the part's application. For parts that require high precision but not necessarily high impact resistance, a glass-filled ABS might be ideal.

Another option is to use high-viscosity ABS. These materials flow less during molding, which can reduce shrinkage. However, they may require higher injection pressures, so equipment capabilities need to be considered.

In some cases, adding nucleating agents can promote uniform crystallization during cooling, further reducing shrinkage. It's all about tailoring the material properties to suit the specific needs of the part.

How does optimizing pressure settings help?

Pressure adjustments might sound technical, but think of it as giving the material a gentle nudge in the right direction.

Increasing packing pressure and extending hold time during molding ensures the cavity is properly filled, compensating for material shrinkage. This reduces voids and maintains part dimensions.

During the injection molding process, the packing pressure is applied after the initial fill to compensate for material shrinkage as it cools. By increasing this pressure, you can force more material into the mold cavity, offsetting the volume loss due to shrinkage.

However, it's crucial not to overdo it. Excessive pressure can cause flashing, where material escapes the mold cavity, leading to defects. It's a delicate balance that requires fine-tuning.

Extending the hold time—the duration the pressure is applied—also helps. This gives the material more time to solidify under pressure, further minimizing shrinkage. It's like holding a mold longer to ensure the shape sets properly.

Optimizing these pressure settings can make a significant difference, especially for thick parts where shrinkage is more pronounced. It's one of those tweaks that might seem minor but has a big impact on the final product.

Conclusion

By carefully managing cooling, selecting the right materials, and fine-tuning pressure settings, we can keep shrinkage under control and produce high-quality ABS parts. But achieving that perfect fit requires a combination of these techniques and a bit of expertise.

Ready to take the next step in improving your ABS part production? Reach out to explore customized solutions tailored to your specific needs. Whether you're looking for guidance on process adjustments or insights into optimal materials, we’re here to help you reduce shrinkage and boost quality.

Check out our in-depth resources or contact us to start a conversation about getting your parts just right!