Introduction

Home appliance manufacturing is shifting from multi-step assembly toward integrated structural design, where assembly complexity directly erodes profit margins. From Xiamen Ruicheng’s long-term cooperation with appliance OEMs, we see that manual assembly, component management, and quality fluctuation have become hidden but critical cost drivers.Restructuring products through process integration is becoming a decisive lever for cost reduction.

In this context, overmolding injection is evolving from a “premium process” into a practical cost-control strategy. When structural design, material selection, and mass-production rhythm are aligned, the cost curve reaches a clear inflection point.

Can overmolding injection reduce appliance assembly steps?

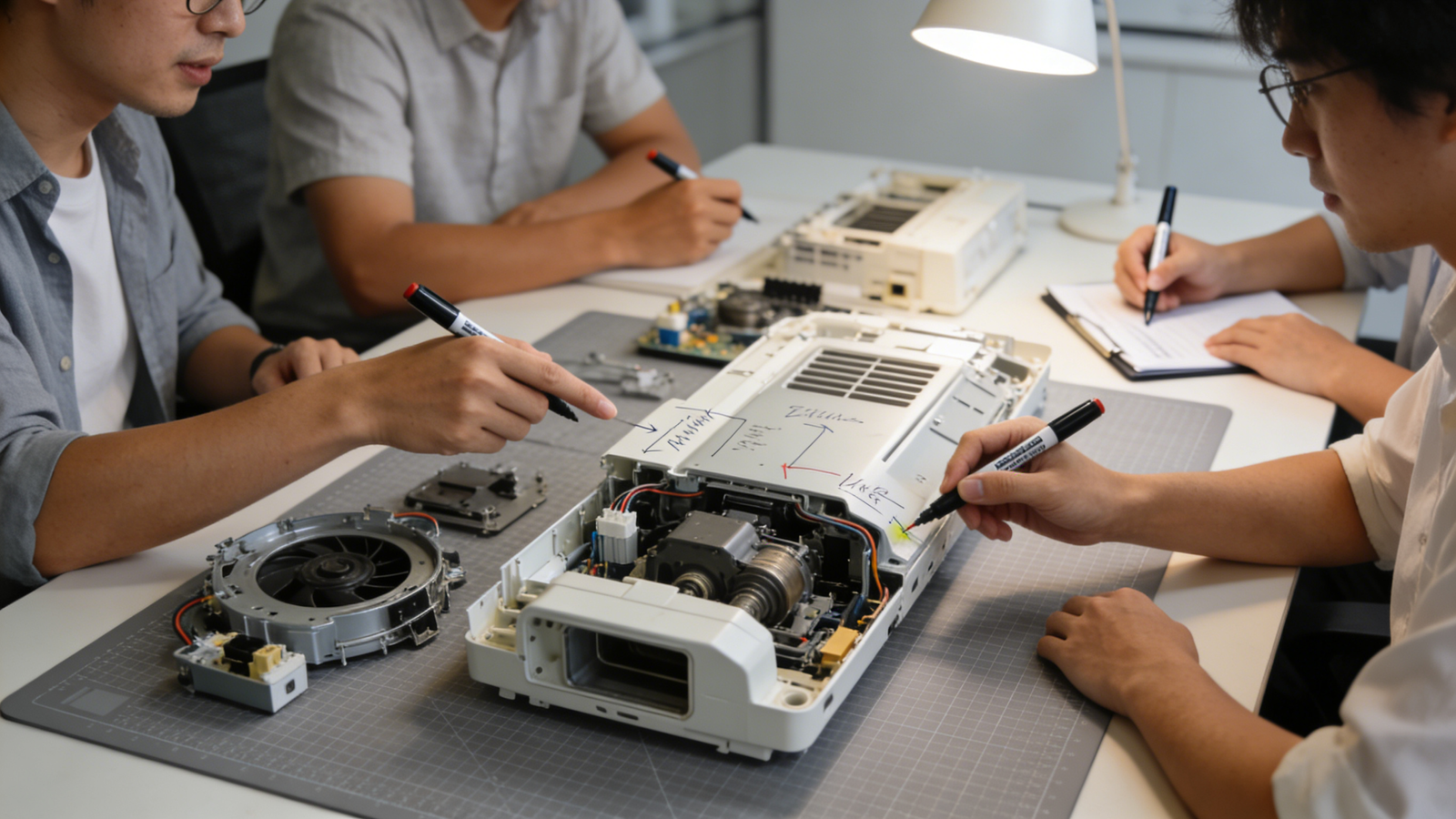

Traditional appliance assembly relies on multiple discrete parts, while overmolding integrates structure and function into a single molded component through Overmolding. In Xiamen Ruicheng’s injection molding projects, fewer assembly steps translate directly into reduced labor dependency and more stable takt times. When components shift from an “assembly logic” to a “molding logic,” assembly costs are naturally compressed upstream. Combined with the consistency of Injection molding, overall production stability improves significantly.

Process integration: Multiple parts are combined inside the mold, eliminating downstream assembly actions.

Stable takt time: Controlled molding cycles replace manual assembly fluctuations.

Quality front-loading: Defects are identified during molding rather than after full assembly.

Simplified management: Fewer parts reduce inventory and logistics complexity.

🙂 Lower assembly complexity fundamentally rewrites the cost structure.

Will mold investment offset the cost benefits of overmolding?

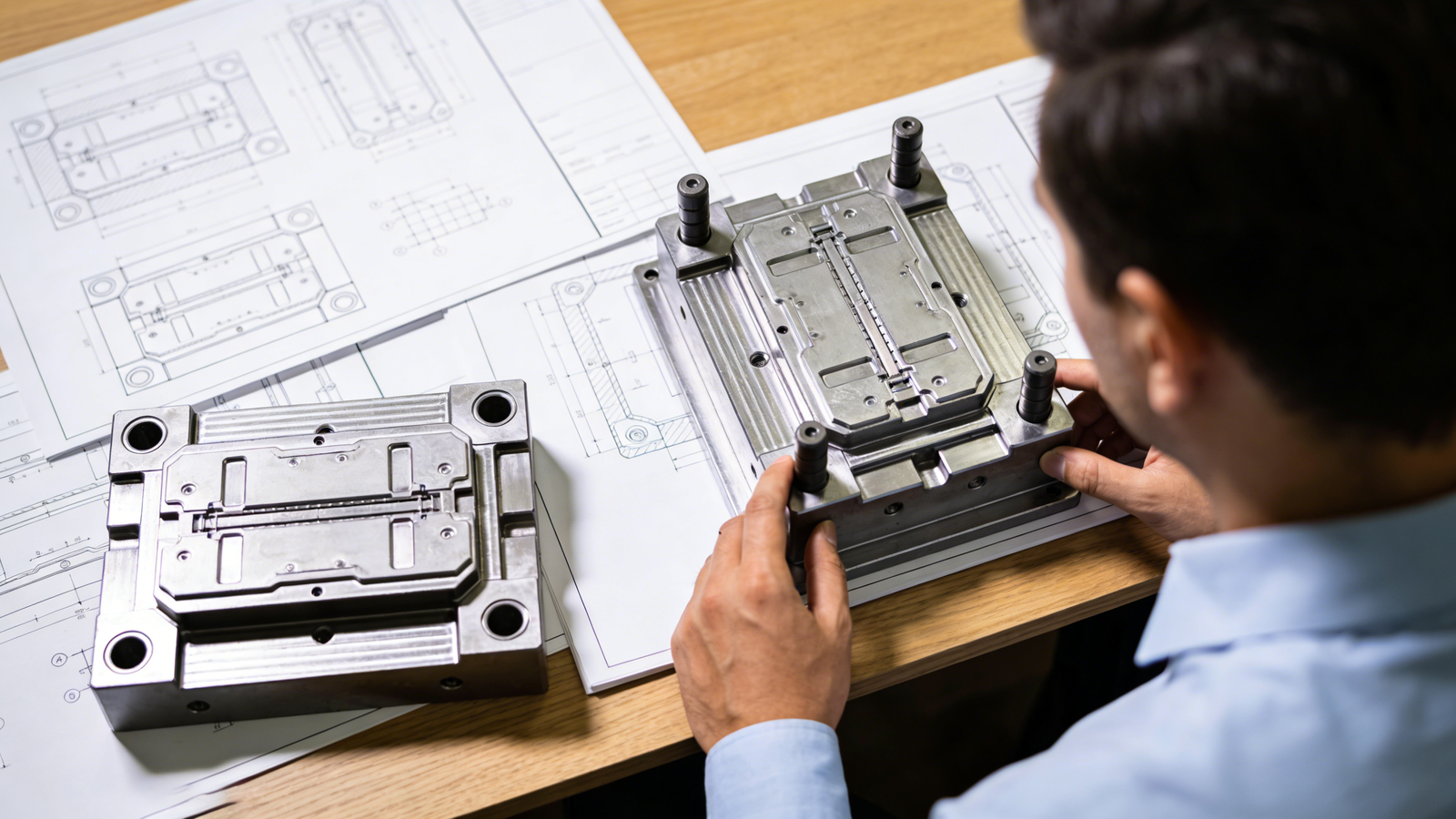

Many buyers worry about higher tooling costs for overmolding, yet from a lifecycle perspective, tooling is a one-time investment. Xiamen Ruicheng typically applies DFM and Tooling strategies to keep mold complexity within mass-production efficiency. Once production volume stabilizes, the unit cost is quickly diluted. More importantly, savings from reduced assembly and lower quality loss often outweigh the initial tooling expense.

Early evaluation: Structural reviews prevent unnecessary mold complexity.

Volume alignment: Cavity count and cycle time are planned based on annual demand.

Tool life planning: Mold durability is matched to the product lifecycle.

Hidden savings: Less rework, scrap, and after-sales risk.

📊 Cost evaluation must consider the entire production chain, not just tooling price.

How does overmolding affect appliance product reliability?

Overmolding is not only a cost tool but also a reliability design strategy. In appliance structural projects, Xiamen Ruicheng validates material combinations through Material compatibility analysis to ensure stable bonding. Integrated structures significantly reduce loosening, noise, and fatigue-related failures. Supported by robust Quality control processes, batch consistency becomes easier to maintain.

Structural integrity: Eliminates risks of screws or clips loosening.

Extended service life: More uniform stress distribution improves durability.

Consistent appearance: Avoids surface damage from secondary assembly.

Test efficiency: Reliability tests better reflect real usage conditions.

🔧 Improved reliability is, in itself, long-term cost reduction.

Value comparison of overmolding in appliance cost reduction

| Comparison Dimension | Traditional Assembly | Overmolding Injection | Cost Impact | Management Impact |

|---|---|---|---|---|

| Number of processes | High | Low | Labor reduction | Simplified |

| Quality variation | High | Low | Less rework | Stable |

| Structural reliability | Medium | High | Lower after-sales cost | Controlled |

| Scalability | Low | High | Lower unit cost | Easy replication |

Want to evaluate whether overmolding fits your product? Feel free to contact us

From cost calculation to decision support

When selecting overmolding, appliance manufacturers need more than a price quote—they need a decision framework. Xiamen Ruicheng typically starts from structural integration potential, annual volume, and quality targets to assess feasibility. Only when process choices align with business objectives can cost advantages truly materialize.

1.Structural assessment: Identify parts and functions suitable for integration.

2.Cost modeling: Compare total cost of ownership instead of unit price alone.

3.Risk forecasting: Evaluate material and process risks in advance.

4.Mass-production planning: Ensure advantages persist at scale.

FAQ – Common procurement questions on overmolding injection

Question: What is the core advantage of your overmolding injection service?

Answer: Xiamen Ruicheng focuses on stable mass production, balancing cost control and reliability through mature mold design and process management.

Question: What information is required to start an overmolding project?

Answer: Basic drawings, expected annual volume, and usage conditions are typically sufficient for an initial feasibility and cost evaluation.

Question: How do lead time and pricing differ by order volume?

Answer: Small batches support structural validation, while larger volumes significantly reduce unit cost with optimized delivery planning.

Question: How are quality issues handled during mass production?

Answer: We operate a clear issue identification and response mechanism to ensure traceability and continuous improvement.

Question: Can you support customized solutions for special appliance structures?

Answer: Yes, material combinations and mold designs can be adjusted to balance performance and cost based on specific operating conditions.

Conclusion

Overmolding injection is not suitable for every appliance component, but for complex, assembly-intensive structures, it often delivers the highest cost efficiency. Xiamen Ruicheng’s experience shows that true cost reduction comes from synchronizing structure, process, and production strategy. When companies evaluate cost from a full lifecycle perspective, the value of overmolding becomes clear.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!