Introduction

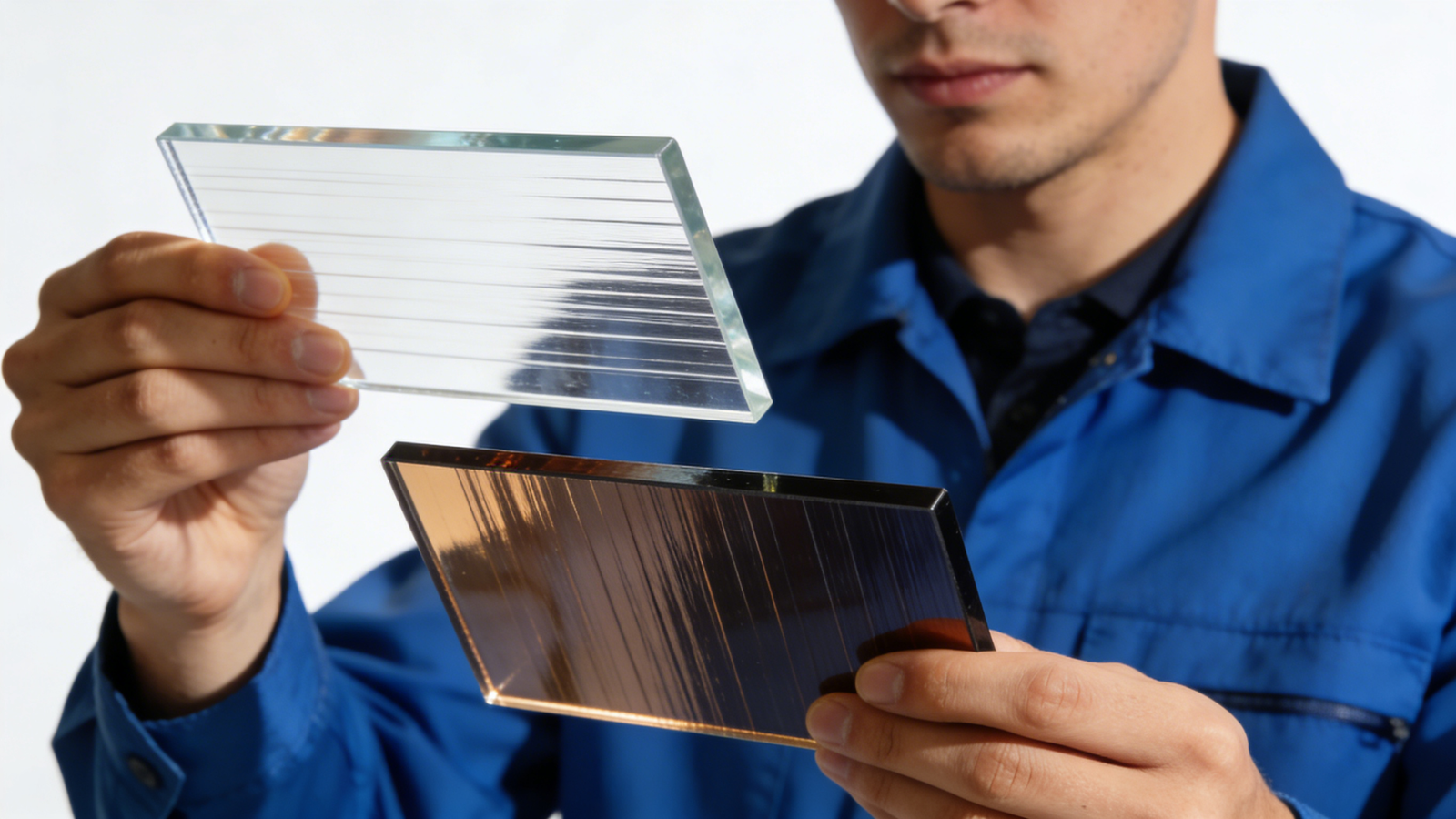

In high-end furniture, commercial interiors, and smart device housings, decorative panels are no longer simple cover parts but key elements that directly define brand perception and product premium. PMMA injection molding, with its high transparency, high gloss, and design flexibility, has become a core manufacturing route for upgrading decorative panels.A truly high-quality decorative panel is not built on stacked parameters, but on a systematic balance of design, process control, and delivery stability.

From the practical perspective of Xiamen Ruicheng, we focus on real procurement challenges such as inconsistent surface appearance, unstable mass-production yields, and weak supplier collaboration. Using process capability rather than visual samples alone to support long-term decisions is the real value of PMMA decorative panels.

How Can PMMA Injection Molding Prevent Uneven Gloss and Flow Marks on Decorative Panels?

In real-world PMMA decorative panel production, uneven gloss, flow marks, and shadow lines often result from insufficient coordination between mold mirror finishing, material flow behavior, and injection parameters. At Xiamen Ruicheng, mold polishing grade, melt shear control, and mold temperature stability are always treated as primary control factors. By systematically aligning PMMA material characteristics with high-gloss injection molding processes, surface appearance becomes stable and repeatable at scale.

Mirror mold finishing: SPI-A1 level polishing is applied to ensure uniform reflection without micro-level light scattering.

Melt flow management: Gate positioning and flow-front control are optimized to minimize visible flow marks.

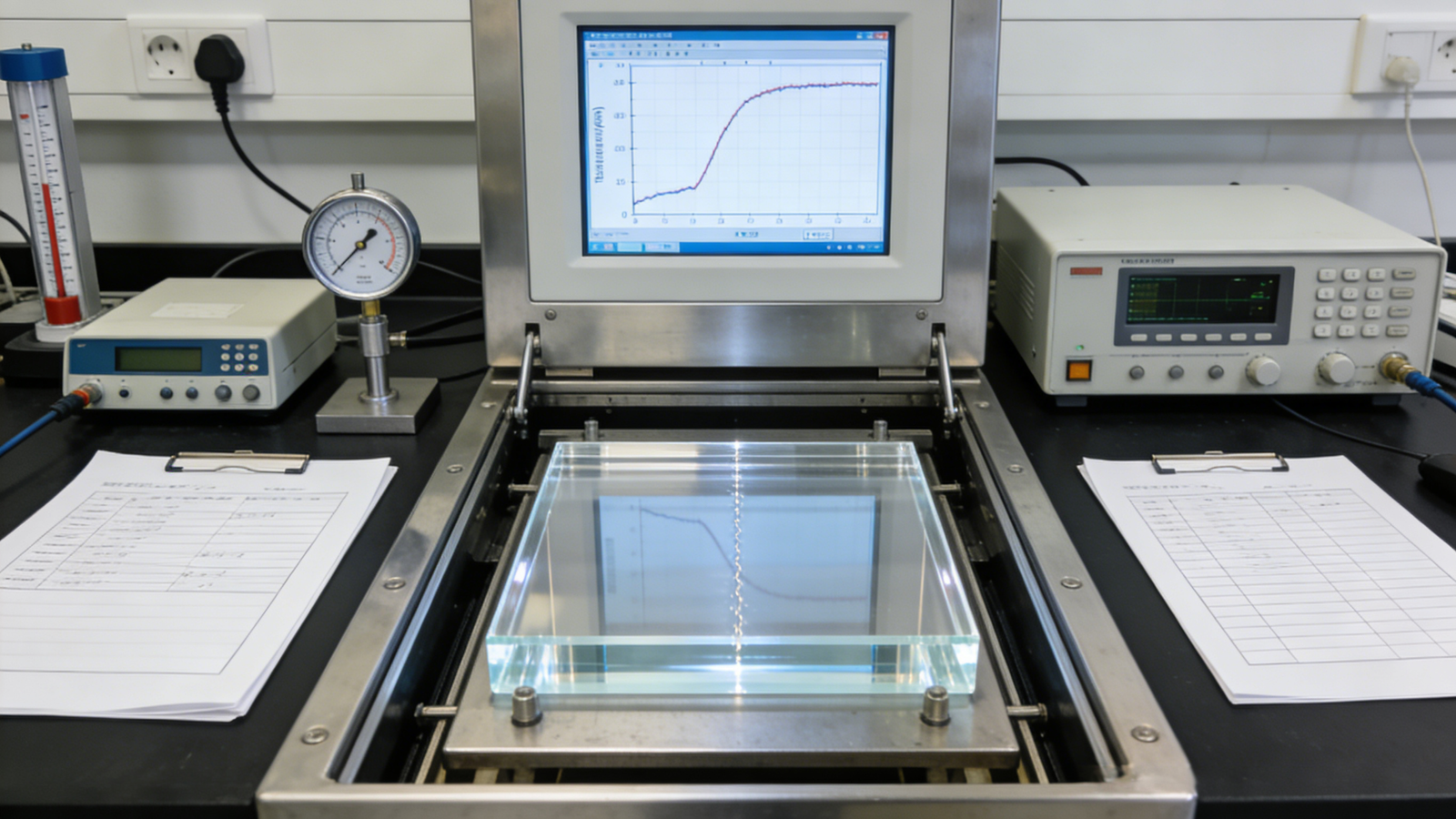

Process window stabilization: Stable mold-temperature profiles replace extreme parameter tuning to reduce batch variation.

Mass-production validation: Appearance consistency checks are introduced during trial runs to prevent later rework.

✨ High gloss is not “tuned in,” it is engineered through mold and process synergy.

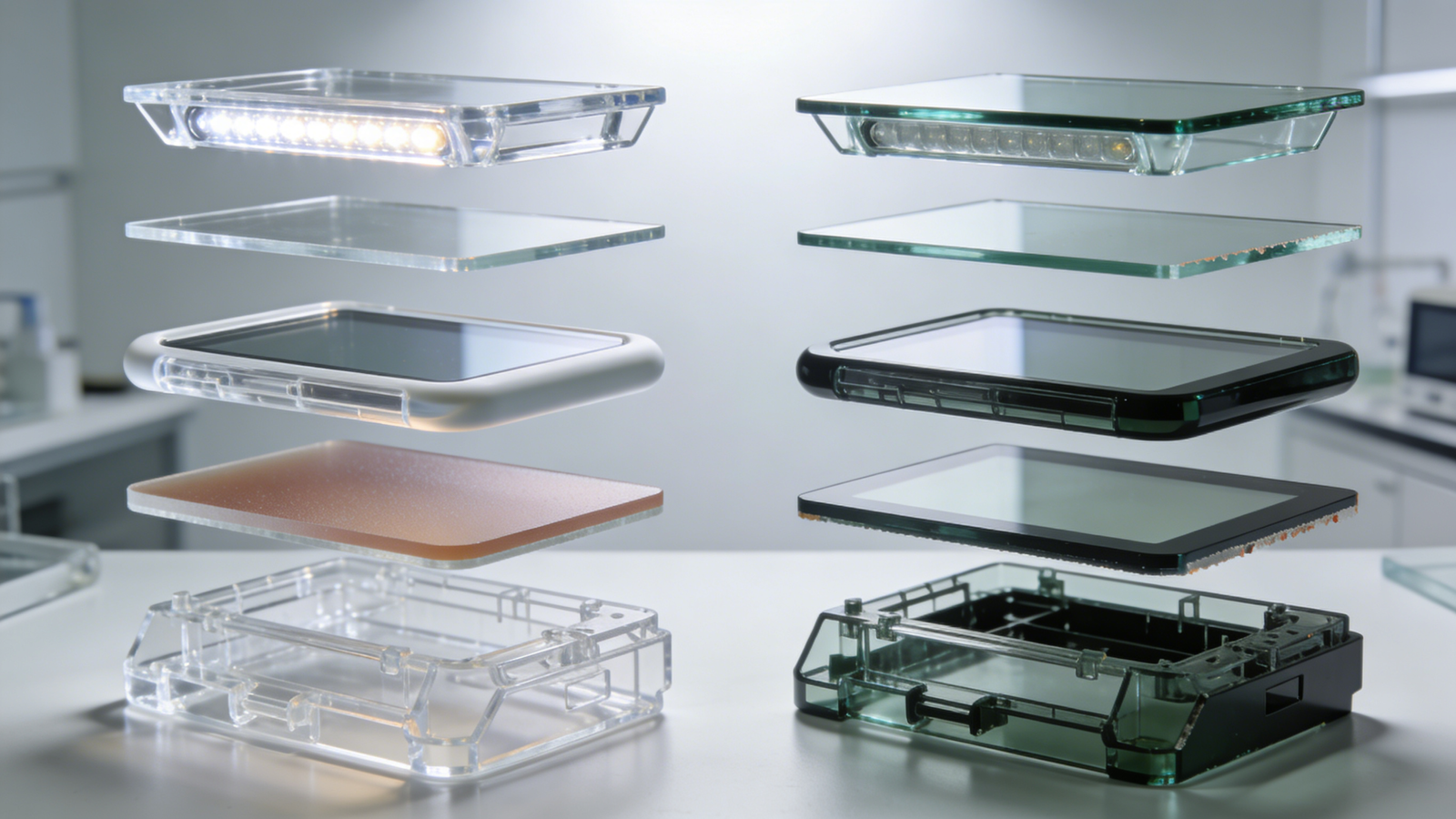

How Does PMMA Injection Molding Balance Surface Aesthetics and Structural Strength?

Decorative panels must look premium while remaining structurally reliable, and PMMA is highly sensitive to wall-thickness variation and residual stress under high-gloss conditions. At Xiamen Ruicheng, decorative requirements and assembly conditions are evaluated simultaneously to avoid sacrificing durability for appearance. Through integrated optimization of injection molding structural design and PMMA mechanical performance, a stable balance between visual quality and service life is achieved.

Gradual wall-thickness transitions: Smooth radii and uniform walls reduce internal stress concentration.

Back-side reinforcement strategies: Ribs are added to non-visible areas to enhance stiffness without affecting appearance.

Assembly compatibility verification: Real assembly tolerances are simulated early to reduce cracking risk in use.

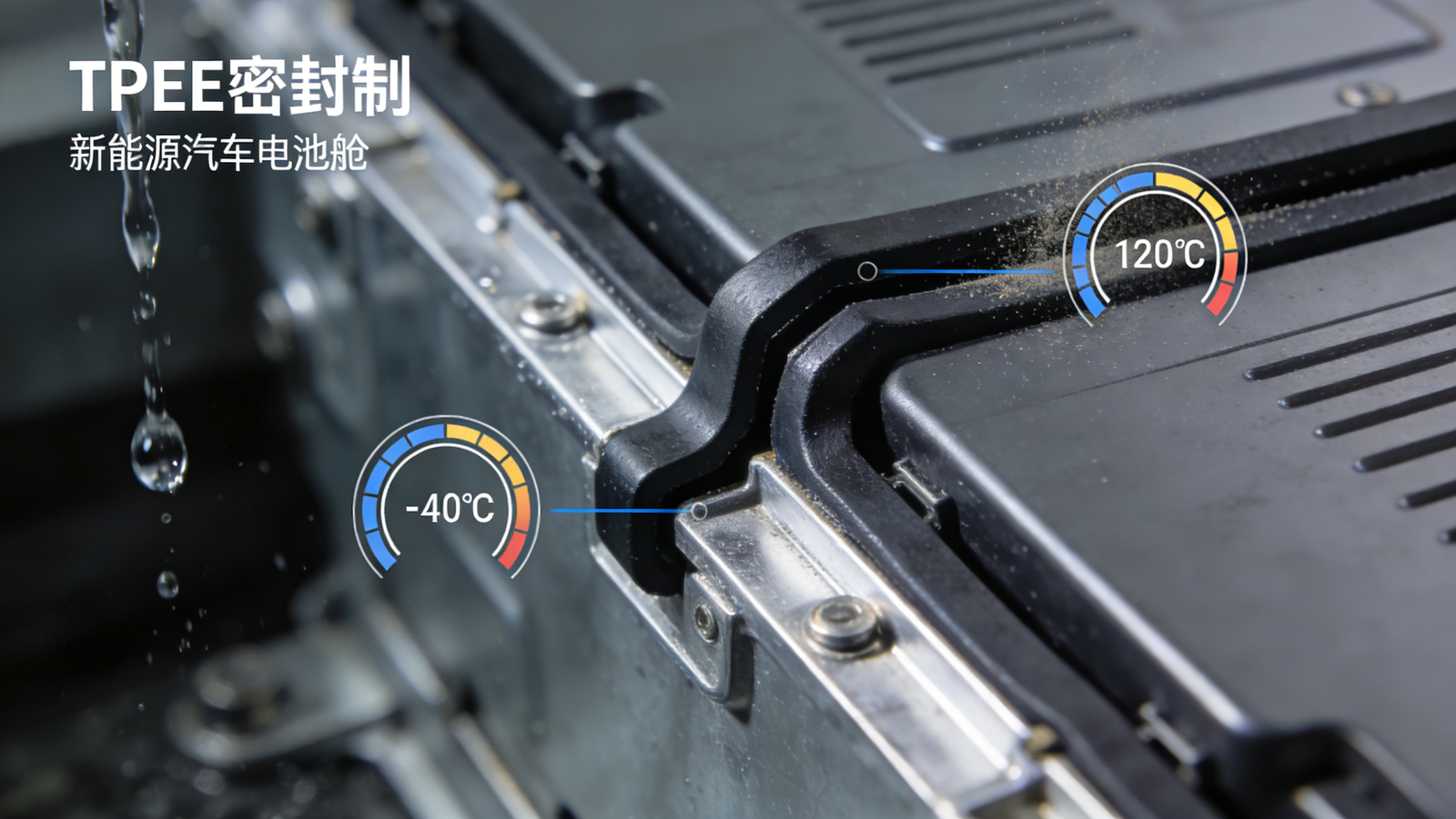

Long-term stability testing: Thermal cycling tests verify both structural and visual reliability.

🧩 True premium panels stand firm in both appearance and performance.

What Risks Do Buyers Most Often Overlook in PMMA Decorative Panel Supply?

Many risks in decorative panel projects come not from the material itself, but from production coordination and mass-production stability. Xiamen Ruicheng focuses on moving risk control forward—from sampling to volume production—rather than fixing issues after delivery. With accumulated experience in injection molding mass-production control and PMMA surface stability, procurement uncertainty can be significantly reduced.

Non-repeatable samples: Excellent samples that fail in mass production often indicate unlocked process windows.

Batch-to-batch color variation: Poor raw-material batch management leads to gloss and transparency fluctuations.

Unstable lead times: Lack of coordination between tooling and production scheduling disrupts project timelines.

Unclear responsibility boundaries: Missing quality criteria increase communication and dispute costs.

⚠️ The biggest risks often hide in phases that seem “problem-free.”

Key Decision Comparison for PMMA Decorative Panel Injection Molding

| Decision Factor | Conventional Injection | Appearance-Focused Solution | Systematic PMMA Injection (Xiamen Ruicheng) | Buyer Impact |

|---|---|---|---|---|

| Surface consistency | High batch variation | Stable in small runs | Stable and repeatable at scale | Less rework |

| Structural reliability | Prone to cracking | Appearance-prioritized | Balanced appearance & strength | Longer lifespan |

| Mass-production control | Experience-dependent | Parameter-sensitive | Fixed process windows | Predictable delivery |

| Service collaboration | One-time delivery | Passive support | Decision-companion approach | Lower coordination cost |

If you are seeking a more reliable injection molding route for decorative panels, contact us to explore practical options.

From Display to Decision: How PMMA Injection Solutions Support Buyer Choices

In decorative panel sourcing, buyers do not need “good-looking samples,” but solutions that can be delivered consistently over time. Xiamen Ruicheng positions PMMA injection molding as a decision-companion service rather than a one-off supply. By integrating early design input, process risk forecasting, and mass-production validation, buyers gain clear expectations and avoid repeated revisions later.

1.Requirement clarification: Application scenarios define appearance and structural priorities.

2.Co-developed solutions: Process constraints are made transparent to avoid hidden risks.

3.Pilot validation: Small-batch data verifies mass-production logic.

4.Long-term collaboration: Stable delivery supports ongoing product iterations.

FAQ Module Title

Question: What is the core quality baseline of your PMMA decorative panels?

Answer: Xiamen Ruicheng defines stable mass production as the core standard, ensuring surface gloss consistency, structural integrity, and batch repeatability through internal process validation and inspection mechanisms.

Question: What information is needed to start a PMMA decorative panel project?

Answer: Basic drawings, application conditions, and expected surface effects allow us to quickly evaluate feasibility and propose optimization suggestions.

Question: How are MOQ and lead times handled for different order volumes?

Answer: Small-batch pilot runs are supported, while production capacity is flexibly arranged for volume orders to ensure stable delivery schedules.

Question: How are appearance or dimensional issues handled after delivery?

Answer: Xiamen Ruicheng follows a clear quality judgment and response mechanism, providing corrective or replacement solutions once issues are confirmed.

Question: Do you support deep customization and long-term cooperation?

Answer: Yes, long-term customized cooperation is supported, with continuous optimization of injection solutions for future product versions.

Conclusion

Creating high-quality decorative panels through PMMA injection molding is a system-level task rather than a single process choice. A truly reliable solution must simultaneously meet appearance, structural integrity, and long-term production stability requirements. Through decision-companion injection molding services, Xiamen Ruicheng helps buyers reduce risk, improve certainty, and unlock sustained value from decorative panel projects.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!