Introduction

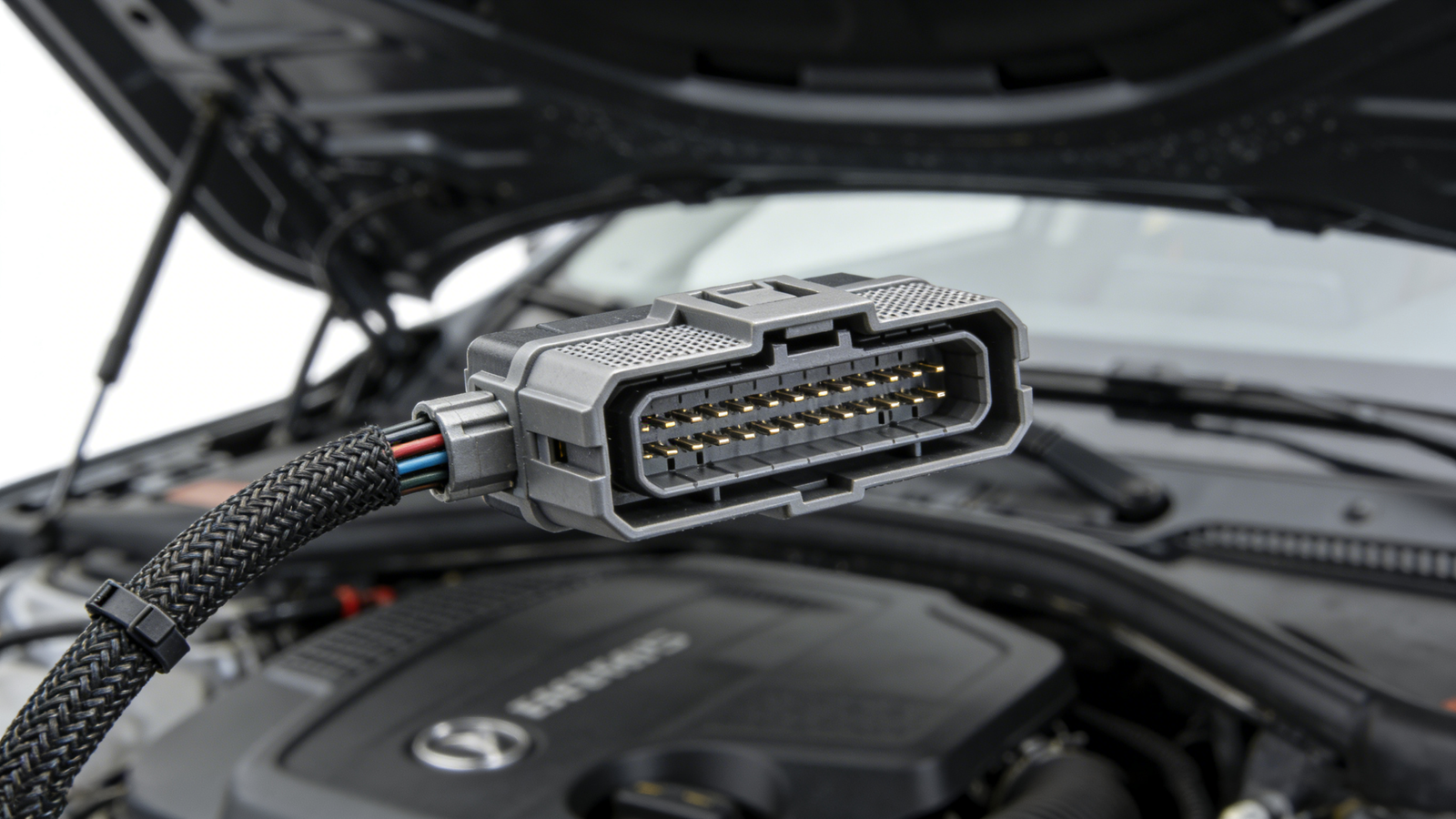

As electronics demand thinner, more powerful, and eco-friendly designs, material selection is crucial. Traditional halogenated flame retardants face regulatory phase-outs due to environmental and corrosion concerns. Halogen-free, flame-retardant PPS (Polyphenylene Sulfide) emerges as the ideal choice for connectors, bobbins, and switches, offering thermal stability, chemical resistance, and intrinsic flame retardancy. However, achieving UL94-V0 rating without added flame retardants poses a significant technical challenge.

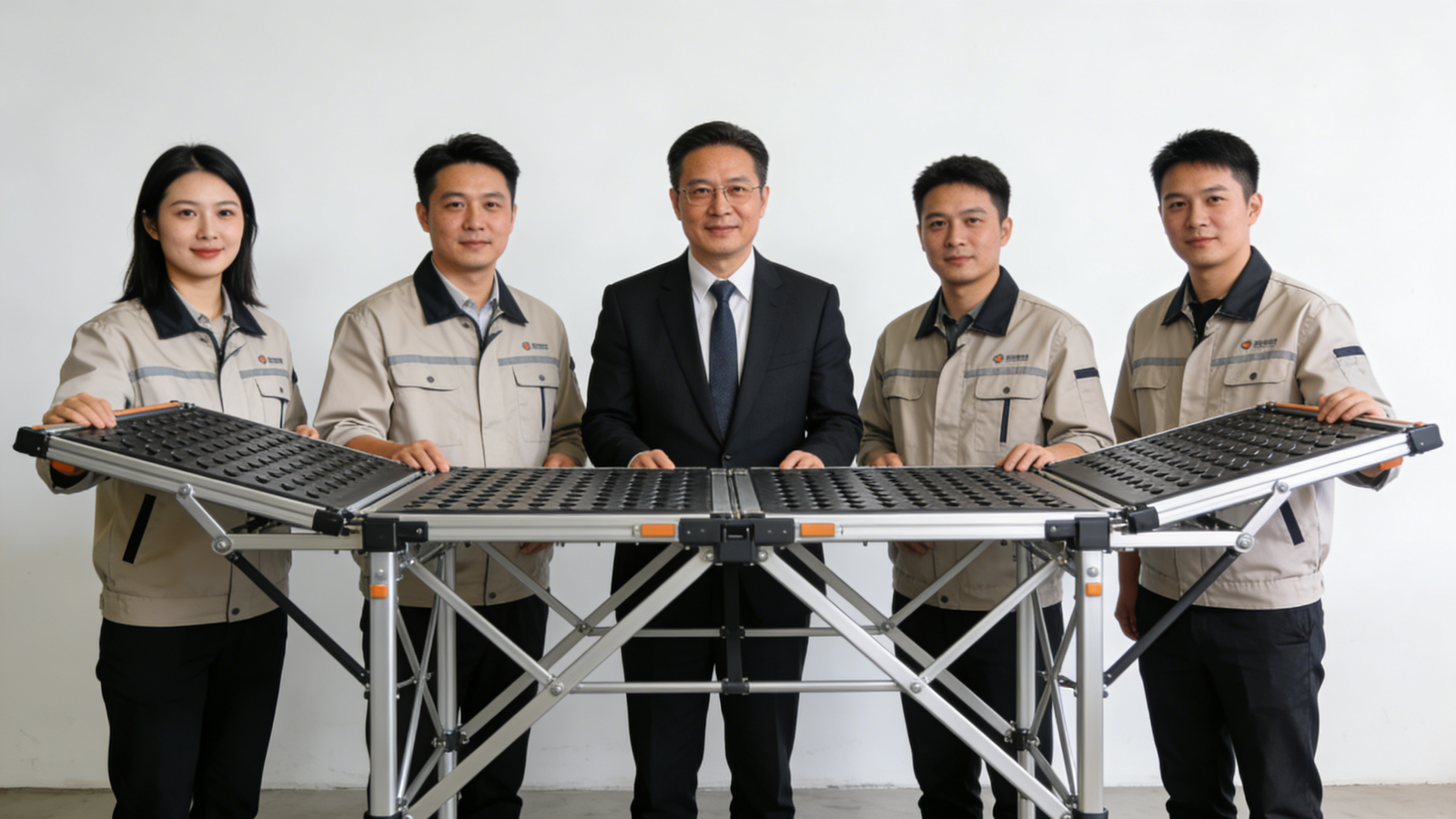

As a high-performance engineering plastic injection molding partner, Xiamen Ruicheng understands that compliance is just the start; you need a systematic guarantee for safety, reliability, and long-term regulatory adherence from the material level. This requires moving beyond material supply to polymer structure design, precise process synergy, and rigorous validation. The real challenge is ensuring every part consistently performs in real-world environments, not just passing a lab test.

What Are the New Challenges of Halogen-Free V0?

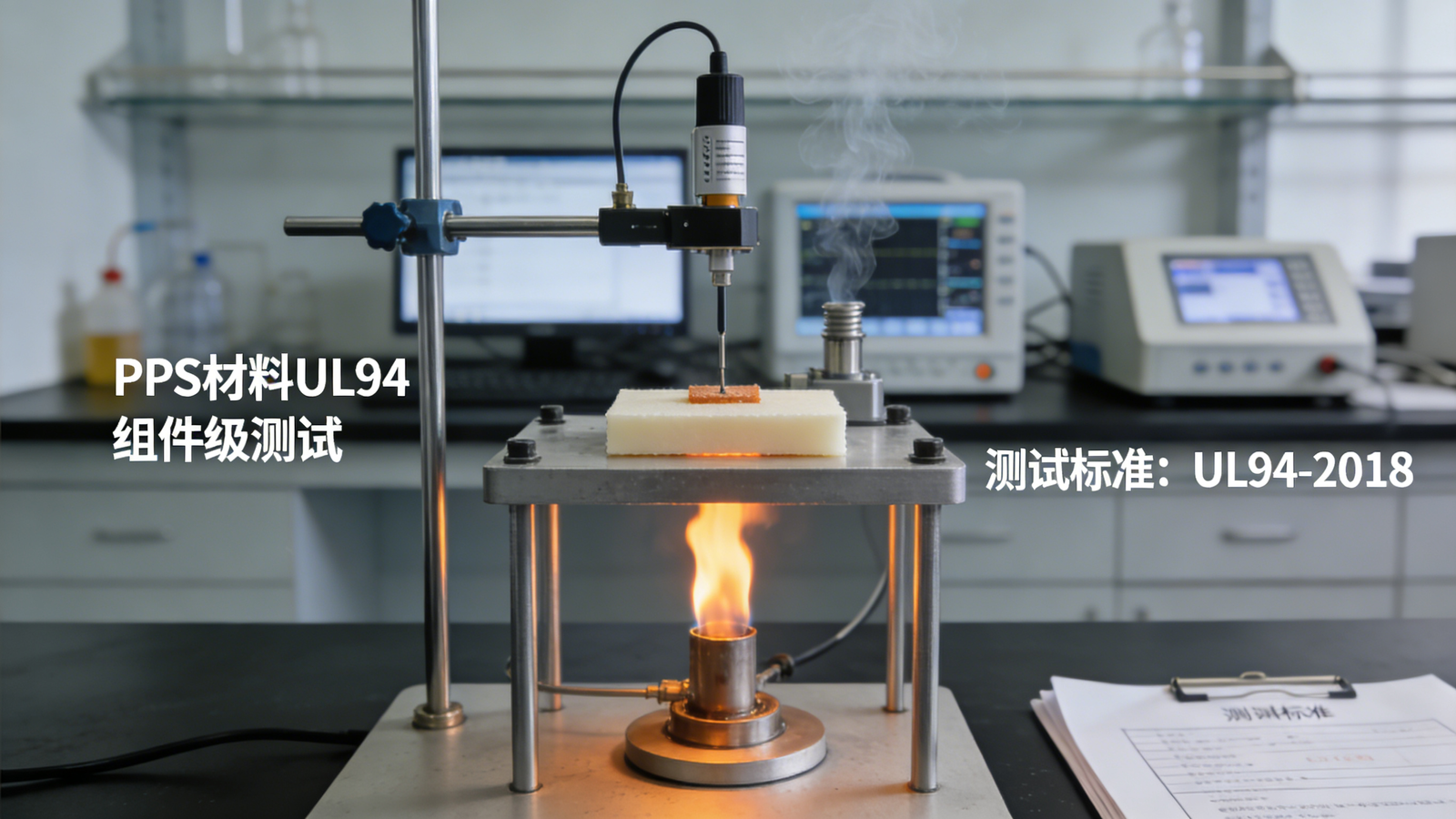

The shift to halogen-free standards raises a critical dilemma: how can PPS achieve self-extinguishing V0 rating without added flame retardants? This isn't a simple substitution. PPS has a high Limiting Oxygen Index (LOI), but its flame retardancy depends on crystallinity, molecular weight, and the skin layer formed during molding. Any process variation can compromise char layer formation, causing performance to drop from V0 to V2 in the UL94 Vertical Burning Test. Xiamen Ruicheng enables V0 without additives by enhancing PPS's char-forming and anti-dripping properties through material modification and precise process control.

Intrinsic Flame Retardant Design: We collaborate with resin partners to optimize PPS's molecular weight and distribution, enabling rapid formation of a uniform, dense char layer upon heating.

Precision Molding Synergy: Precise mold temperature, injection speed, and holding pressure induce a high-crystallinity surface layer that acts as a barrier to oxygen and flame spread.

Stable Char Layer Construction: Specialized runner and cooling designs optimize melt flow, ensuring a continuous flame-retardant char layer, especially in thin walls and ribs.

Full-Process Monitoring: Online process monitoring and batch combustion tests ensure batch-to-batch consistency in flame retardant performance.

🔥 Achieving V0 without additives is a precise collaboration from molecular design to molding process.

How is Flame Retardancy Achieved Through Material Intrinsic Properties?

Eliminating external flame retardants requires embedding flame retardancy into the PPS molecular structure. Xiamen Ruicheng's PPS Composite Technology introduces structural units during polymerization that promote char formation and free radical capture. This structure cross-links into an intumescent char layer at high temperatures, isolating heat and oxygen without toxic gases. We also ensure thermal-oxidative stability for long-term performance under high-temperature operation, excelling in tests like the Glow-Wire Flammability Index.

Molecular Structure Optimization: Aromatic rings and cross-linking points increase char yield and strength for rapid self-extinguishing.

Thermal Stability Enhancement: Optimized polymerization raises decomposition temperature, delaying combustion onset.

Synergistic Enhancement: Nanoscale fillers improve char layer density and continuity without compromising mechanical properties.

Purification Treatment: Removing catalyst residues and impurities eliminates ignition points, ensuring material purity and reliability.

🔬 Unlocking the material's intrinsic flame-retardant potential balances eco-friendliness and safety.

How Does the Molding Process Synergize to Ensure Stable V0?

Even with superior material, improper molding can negate flame-retardant efforts. Xiamen Ruicheng's "Process-Structure-Performance" database quickly identifies the optimal injection parameters for each geometry. For example, higher mold temperature improves crystallization and flame-retardant barrier but requires balancing cycle time and warpage. Precise injection speed avoids shear-induced degradation. Our meticulous Mold Temperature Control and screw plastication ensure every shot delivers stable V0 performance.

Mold Thermal Management: High-precision, zone-controlled mold temperatures maintain optimal crystallization for a dense surface flame-retardant layer.

Shear and Thermal History Control: Optimized screw configuration and injection profiles minimize shear heat and residence time, preventing material degradation.

Precise Pressure Transmission: Multi-stage holding pressure enhances internal density, reducing defects that could propagate flame.

Closed-Loop Molding Feedback: IoT sensors monitor process parameters, linking to quality data for automatic adjustment and mass production consistency.

⚙️ Precision processing awakens the material's flame-retardant potential; stability comes from mastering every detail.

Comparison of Four Halogen-Free PPS Flame Retardant Solutions

| Feature | Traditional Halogenated PPS | Conventional Halogen-Free PPS | Ruicheng Intrinsic PPS (Additive-Free) | Ruicheng Enhanced Intrinsic PPS |

|---|---|---|---|---|

| Mechanism | Bromine/Antimony (Gas Phase) | Phosphorus/Nitrogen (Intumescent Char) | Material Intrinsic Char-Forming | Intrinsic Char + Synergistic Enhancement |

| UL94 Rating | V0 (Halogenated) | V0 | V0 | V0 (More Stable) |

| Environmental | Contains Halogens | Halogen-Free, May Contain P | Halogen-Free, No Added FRs | Halogen-Free, No Added FRs |

| Electrical Properties | Fair, Risk of Corrosion | Good | Excellent, Low Dk, High CTI | Outstanding, Very Low Loss |

| Long-Term Thermal Aging | Risk of Blooming, Degradation | Good | Excellent, No Blooming Risk | Excellent, Longer Lifetime |

| Material Cost | Low | Medium | Medium-High | High |

| Total Cost Consideration | High Compliance/Repair Cost | Balanced Choice | Low Total Cost of Ownership | Best Value for High-End Apps |

| Typical Applications | Being Phased Out | Consumer Electronics | Automotive Electronics, Connectors | 5G Base Stations, New Energy HV Parts |

Unsure which solution fits your needs? Get a customized analysis and free samples by contacting us.

The Holistic Value of Halogen-Free PPS Solutions

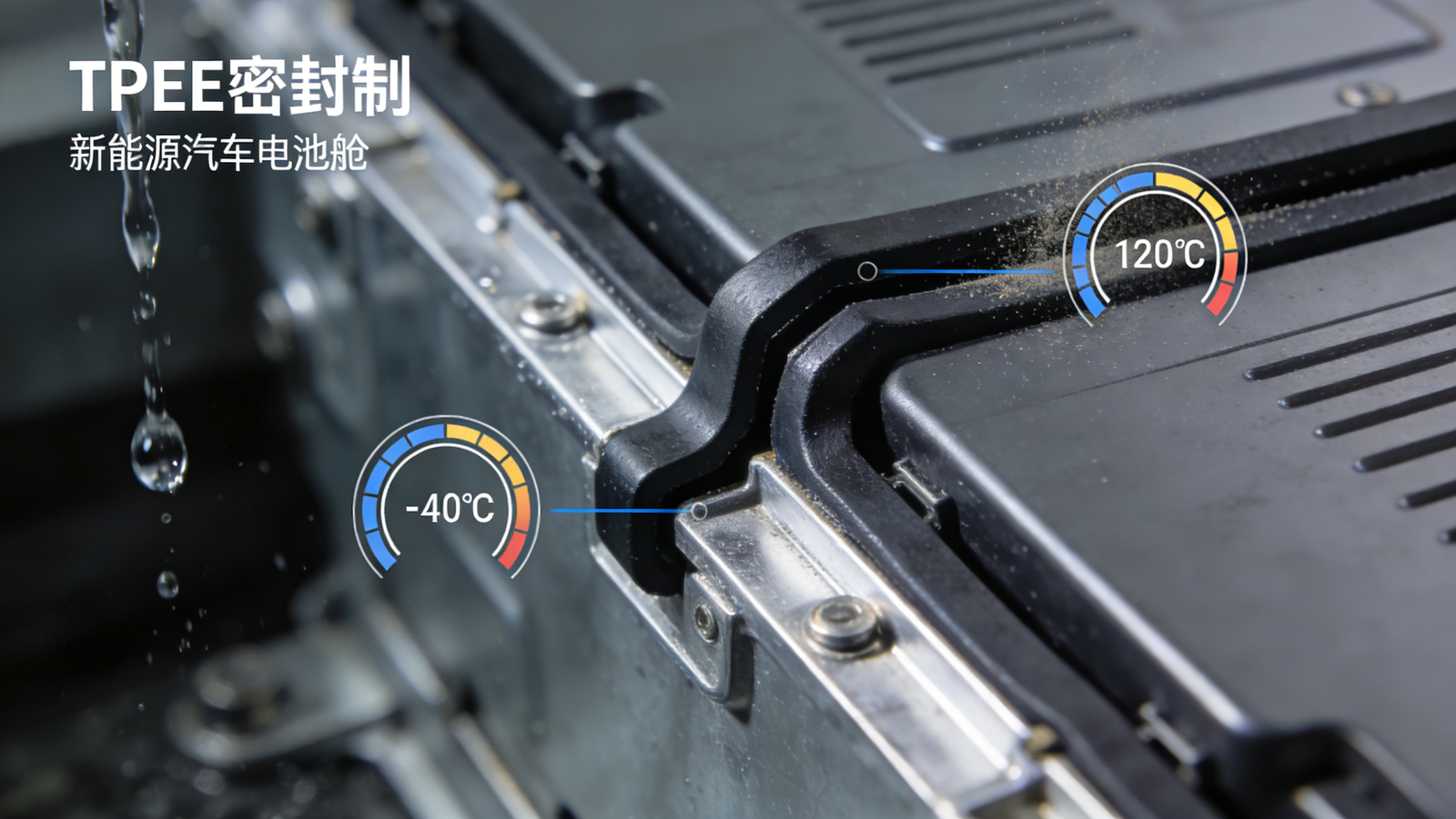

Choosing Xiamen Ruicheng's additive-free PPS solution delivers more than a UL94-V0 report. We provide a lifecycle value-driven solution ensuring component reliability in harsh environments. Intrinsic flame retardancy means homogeneous material with no phase separation, leading to superior mechanical strength, dimensional stability, and chemical resistance. This is vital for automotive under-hood parts or outdoor communication equipment. Clean material composition avoids corrosion from flame retardant migration, enhancing end-product reliability.

1.High-Reliability Design: Material-process integration ensures stability under thermal, mechanical, and environmental stress, reducing field failures.

2.Comprehensive Compliance Safety: Meets UL94 V0, RoHS, REACH, and IEC Glow-Wire, facilitating global market access.

3.Production Efficiency Optimization: Stable process windows reduce setup time and scrap, enhancing manufacturing efficiency.

4.Long-Term Cost Advantage: Higher unit material cost is offset by increased yield, longer service life, and reduced post-sales risks.

Frequently Asked Questions (FAQ)

Question: Is your UL94-V0 certification for additive-free PPS specific to a material grade or the final part?

Answer: Our certification covers material to final part. The PPS Composite Material is UL Yellow Card recognized. We conduct component-level UL94 testing based on your part geometry, wall thickness, and process, providing reports for end-client audits.

Question: What information is needed for a rapid assessment of a halogen-free V0 PPS molding project?

Answer: Provide 3D drawing (STEP/IGS), operating temperature range, sealing/press-fit requirements, and annual forecast. We'll perform DFM Analysis and give material selection, process feasibility, and a sample plan within 3 business days. Remote meetings are available for complex geometries.

Question: What are the MOQ, lead time, and payment terms for different volumes?

Answer: Prototyping MOQ: 50-100 pieces, lead time 2-3 weeks. Pilot (500-5k pieces): 3-4 weeks. Mass production (10k+): 4-5 weeks. Urgent orders can be expedited. Payment terms (TT/LC) are negotiable based on order value and cooperation stage.

Question: How do you address inconsistent flame retardant performance in purchased parts?

Answer: We initiate quality traceability immediately, confirming batch and storage conditions. Within 48 hours, we provide third-party test reports for retained samples and may arrange on-site analysis. If the issue is our manufacturing, we commit to unconditional rework/reproduction and cover costs. All mass production products come with inspection reports and batch traceability.

Question: Can you customize PPS for arc resistance or color needs?

Answer: Yes. We can adjust formulations for metrics like Comparative Tracking Index (CTI) (e.g., CTI 600V) and support custom color matching with Pantone alignment. Custom development requires detailed specs and ~2 kg sample for testing, with a 4-6 week cycle.

Conclusion

Achieving UL94-V0 halogen-free PPS parts without additives is a systems feat merging materials science, precision processing, and quality management. Through closed-loop control from intrinsic design to molding, Xiamen Ruicheng not only ensures compliance but enhances component reliability and overall value. We aim to be your decision-making partner, using technological solutions and stable production to help you meet future market challenges.

For expert assistance in Halogen-Free, Additive-Free PPS Injection Molding, visit our resource center or contact us. Let’s help you scale up with precision and efficiency!