The molding quality of injection parts heavily depends on controlling wall thickness during the design phase. Maintaining uniform wall thickness improves product performance and directly impacts production efficiency and mold life.

Modern injection production has shifted from “making it work” to “making it well.” Wall thickness, as a fundamental design parameter, is now a core element in optimization. It serves as a vital bridge between structural design and process execution.

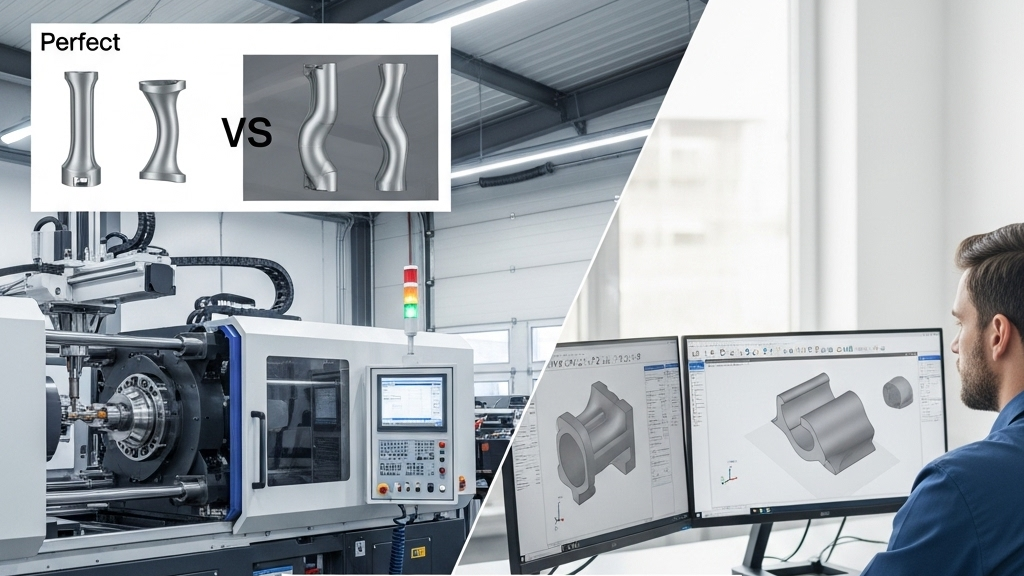

What molding defects are caused by uneven wall thickness?

Uneven wall thickness typically leads to inconsistent cooling rates, causing material stress concentrations and warping. This severely impacts product appearance and functional stability.

- Sink Marks: Thick areas cool slowly, forming surface depressions.

- Warping: Uneven cooling creates residual stress.

- Bubbles and Flow Marks: Excessive thickness traps gases.

- Increased Mold Wear: Non-uniform cooling shortens mold lifespan.

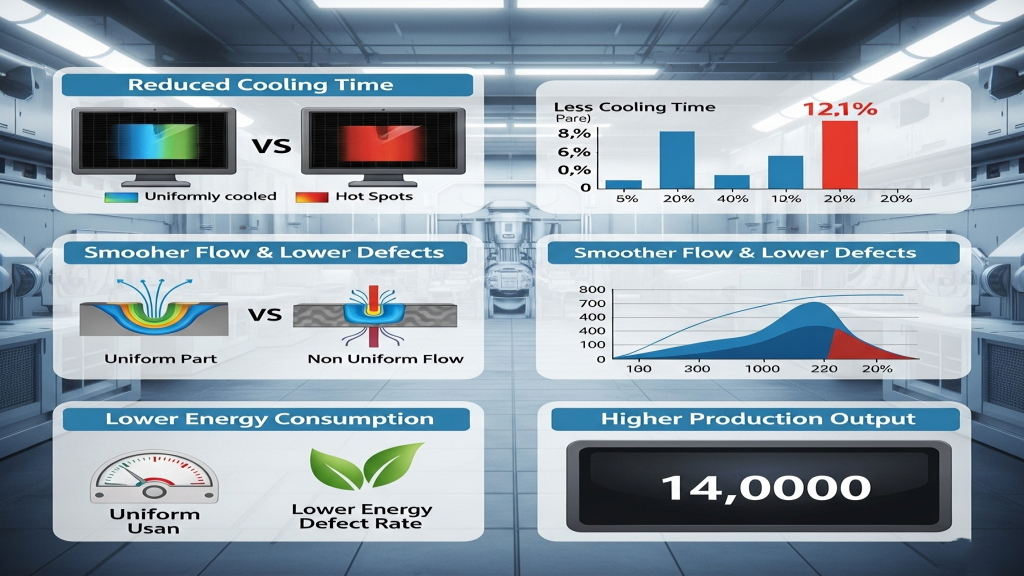

Why does uniform wall thickness improve production efficiency?

Injection molding cycle time is limited by cooling time. Uniform thickness significantly shortens cooling duration, increasing hourly output. This is especially important for high-volume, cost-sensitive production.

- Reduced Cooling Time: Simultaneous part cooling saves time.

- Smoother Flow: Balanced melt pressure lowers defect rates.

- More Stable Mold Cycles: Uniform temperature improves repeatability.

- Lower Energy Consumption: Less heating and cooling saves power.

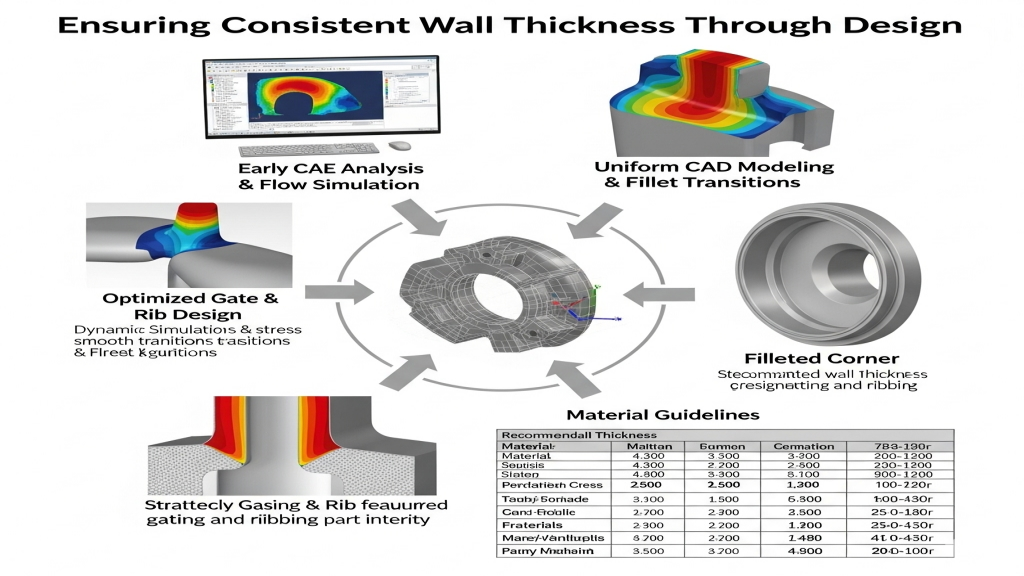

How to ensure consistent wall thickness through design?

Early-stage CAE analysis and flow simulation can foresee thickness issues. Optimizing gate locations, rib designs, and structural transitions enhances overall consistency.

- Uniform CAD Modeling: Consistency starts at the design source.

- Fillet Transitions: Prevents localized stress.

- Flow Simulation Support: Identifies potential risk zones.

- Follow Material Guidelines: Recommended thickness ranges must be respected.

Comparative Strategies for Wall Thickness Control

| Strategy | Suitable For | Precision | Flow Analysis Need | Sink Risk | Cost | Stress Risk | Recommendation |

|---|---|---|---|---|---|---|---|

| Uniform Wall Design | Structural | High | Medium | Low | Medium | Low | ★★★★★ |

| Transition Optimization | Covers | Medium | High | Medium | High | Medium | ★★★★☆ |

| Reinforced Ribs | Thin-walled | Medium | High | Medium | Medium | Medium | ★★★☆☆ |

| Additional Supports | Large Parts | Low | Low | High | Low | High | ★★☆☆☆ |

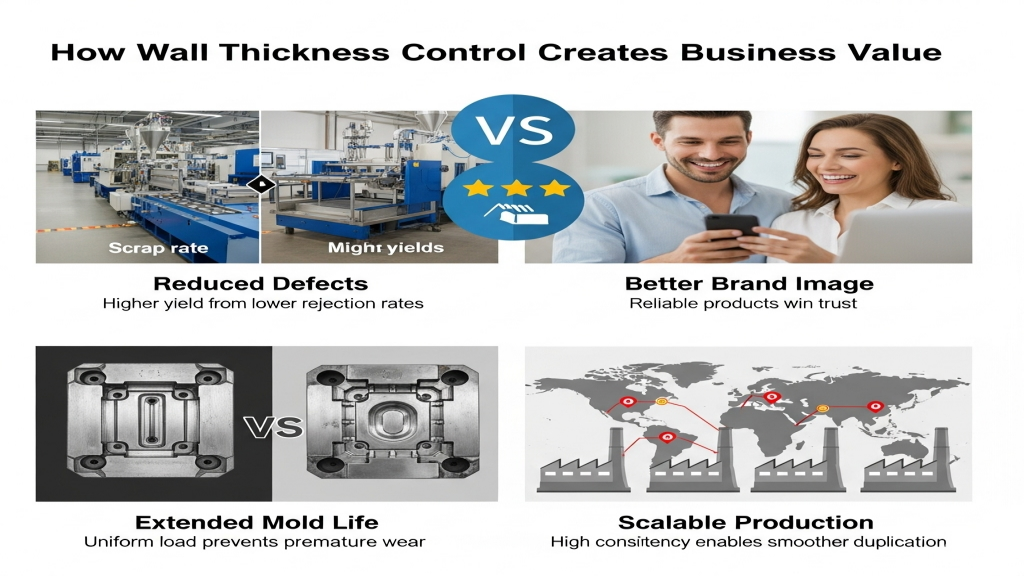

How does wall thickness control create business value?

Wall thickness isn’t just about structural integrity; it directly affects unit cost and lead time. Good design reduces scrap, shortens delivery, and enhances customer satisfaction.

1.Reduced Defects: Higher yield from lower rejection rates.

2.Better Brand Image: Reliable products win trust.

3.Extended Mold Life: Uniform load prevents premature wear.

4.Scalable Production: High consistency enables smoother duplication.

Conclusion

Uniform wall thickness is not just a design principle but a cornerstone that links product quality, process efficiency, and business success. It is truly the “golden rule” of injection molding design. In real-world projects, managing wall thickness is managing your value in every detail.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!