Introduction

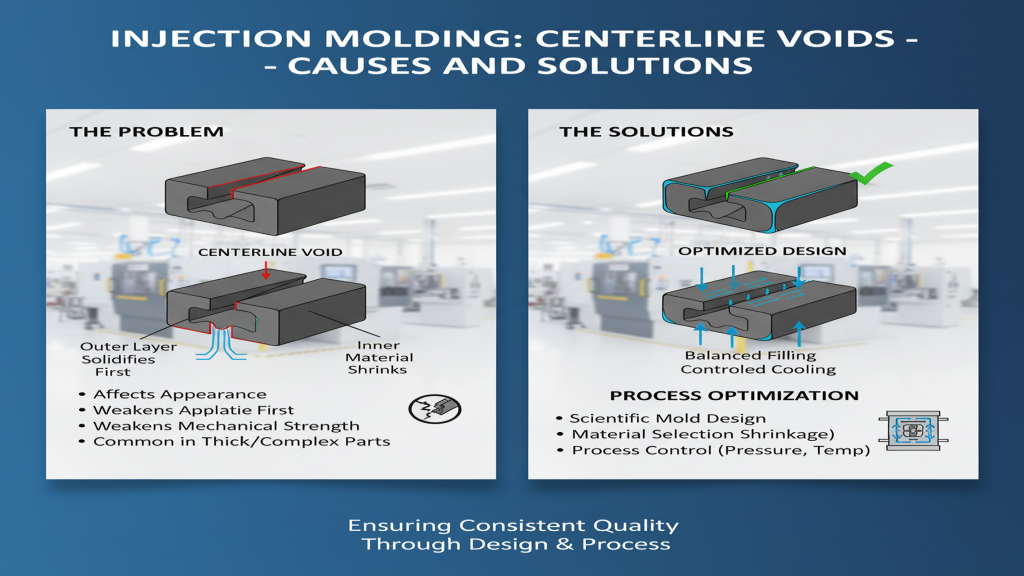

In injection molding production, voids in the centerline area often indicate imbalance in the filling and cooling process. This defect not only affects appearance but also weakens the overall mechanical performance of the part. Manufacturers must address the issue through design and process optimization to ensure consistent quality.

Centerline voids are commonly found in thick-walled and complex-shaped parts. During cooling, the outer layer solidifies first while the inner material remains fluid, resulting in shrinkage cavities. Only through scientific mold design and material selection can this problem be significantly reduced.

Why Do Injection Molded Parts Develop Voids in the Centerline Area?

The formation of centerline voids is mainly due to uneven cooling rates and material shrinkage. In thick sections, the surface cools and hardens first, while the core shrinks and leaves behind cavities. This directly reduces part strength and durability.

- Material Shrinkage: Different shrinkage rates across materials cause internal inconsistencies.

- Mold Design: Poor venting design prevents complete filling.

- Process Parameters: Insufficient packing pressure or short cooling time intensify defects.

- Part Structure: Complex wall thickness increases the likelihood of center voids.

😊 Centerline voids are primarily caused by uneven shrinkage and cooling, requiring systematic optimization.

How Do Centerline Voids Affect Part Performance?

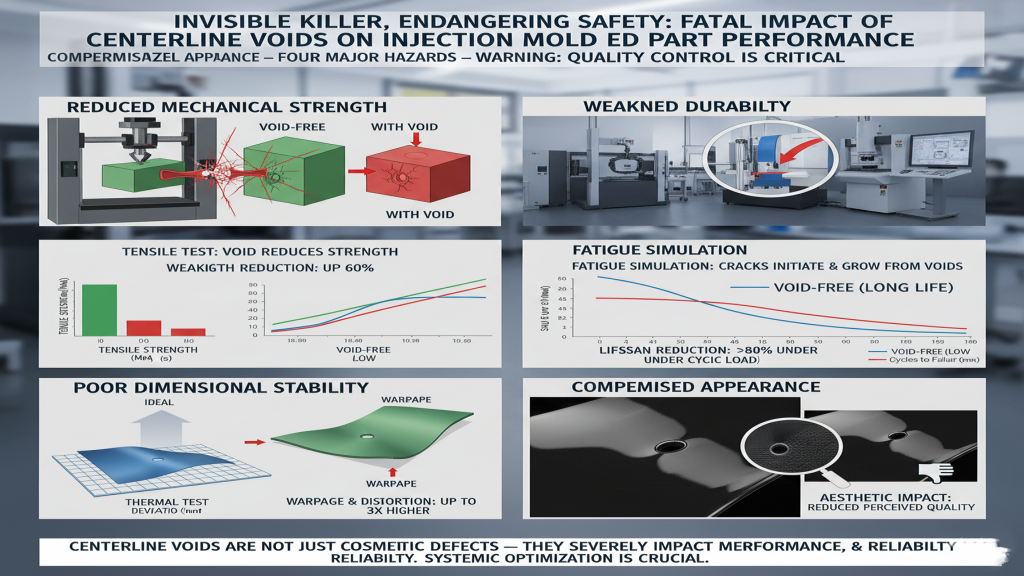

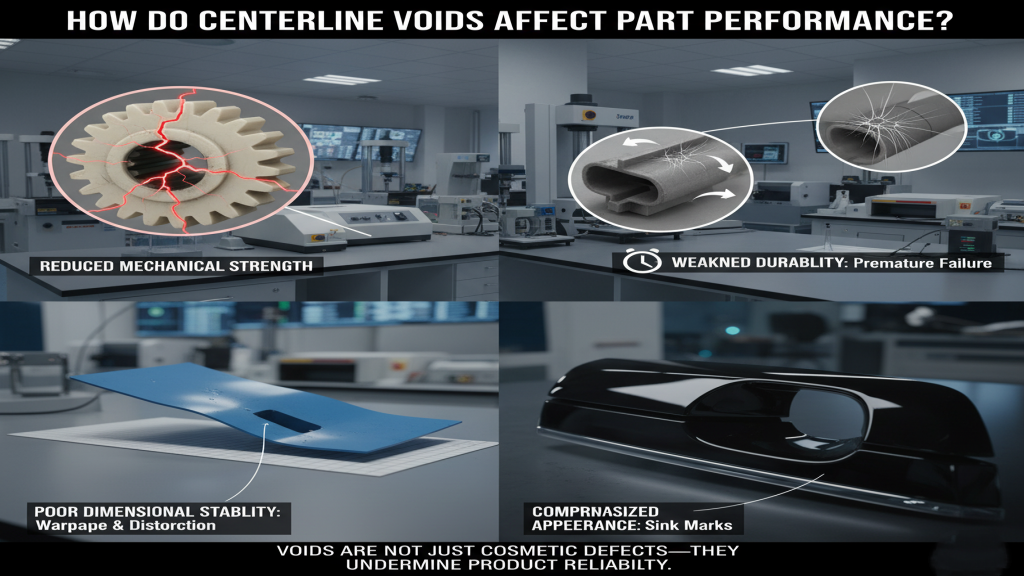

Centerline voids impact not only visual quality but also long-term reliability. Internal cavities reduce load-bearing capacity, making parts prone to cracking under stress. In industries such as automotive, electronics, and medical devices, such flaws pose critical risks to safety and performance.

- Reduced Mechanical Strength: Lower tensile and compressive strength.

- Weakened Durability: Cyclic loading accelerates fatigue cracks.

- Poor Dimensional Stability: Higher risk of deformation and warpage.

- Weakened Durability: Cyclic loadingaccelerates fatigue cracks.Compromised Appearance: Surfaces show sink marks and waviness.

⚠️ Voids are not just cosmetic defects—they undermine product reliability.

How Can Centerline Voids Be Effectively Minimized?

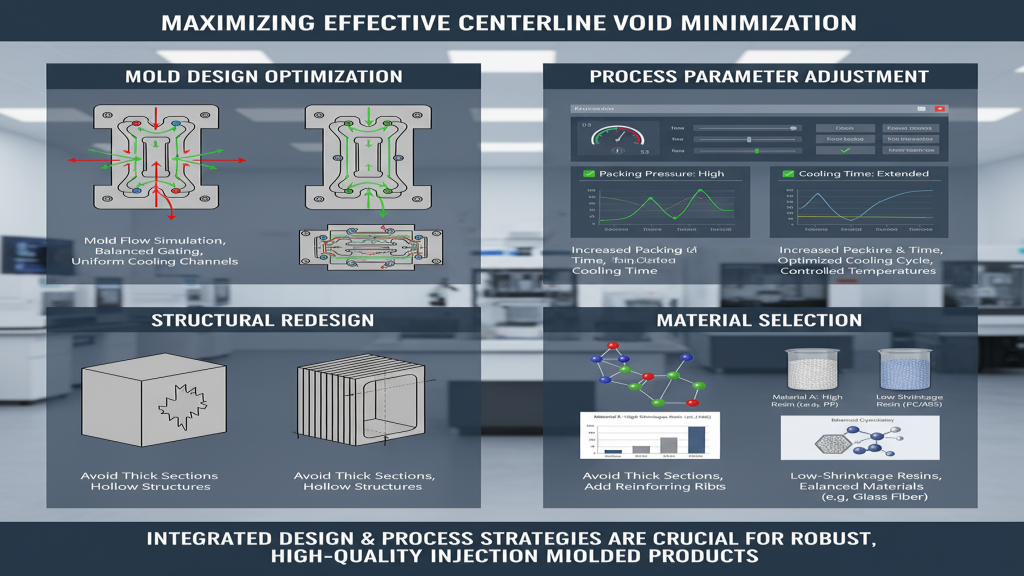

Minimizing centerline voids requires combined improvements in design and processing. Optimizing packing pressure, cooling, and mold gating layouts is essential to solving this defect.

- Mold Flow Optimization: Weakened DurabilityCyclic loading accelerates fatigue cracks.Proper gate placementensures balanced filling.

- Process Adjustment: Longer packing time and optimized cooling cycle.

- Structural Redesign: Avoid thick sections, adopt hollow structures.

- Material Selection: Use low-shrinkage resins with balanced crystallinity.

🔧 A combined design and process approach can significantly reduce void risks.

Comparison of Solutions

| Solution | Cost Level | Effectiveness | Applicability |

|---|---|---|---|

| Mold Design Upgrade | High | High | Universal |

| Process Adjustment | Medium | Medium | Most Products |

| Material Replacement | Medium-High | High | Special Needs |

| Structural Redesign | Medium | Medium-High | Thick-Walled |

Looking for a tailored void-elimination solution? Let’s talk contact us

Expansion

Centerline voids are not caused by a single factor, but by the combined effect of mold design, processing, and material properties. In customized injection molding services, the supplier’s expertise and simulation capabilities play a critical role. With CAE analysis and process validation, void risks can be predicted and avoided in advance.

1.Simulation Tools: Use CAE software to predict cooling and shrinkage.

2.Mold Innovation: Hot runner systems improve flow and balance.

3.Material Development: Low-shrinkage compounds for precision molding.

4.Production Monitoring: Real-time adjustments reduce defect rate.

Conclusion

Centerline voids are a common internal defect in injection molding, but they are manageable. Through optimized mold design, proper processing parameters, and the right material choice, manufacturers can significantly reduce void risks. Preventive solutions are always more cost-effective than rework, especially for high-value applications. By addressing this challenge, producers not only enhance part performance but also strengthen their market competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!