Introduction

PMMA, with its outstanding optical properties and excellent adaptability to molding, has been widely applied in lighting, automotive, and architectural fields. It not only delivers high transparency but also meets the demands of complex injection molding. This combination of performance and versatility has earned it the title of the “Queen of Plastics.”

In addition to its performance, PMMA’s weather resistance and lightweight nature make it stand out in transparent components. Whether for mass production or customized development, it brings added value. Its balance of aesthetics and functionality makes PMMA one of the preferred materials in injection molding.

What Makes PMMA’s Optical Properties Unique?

PMMA offers exceptional light transmittance and excellent refractive properties, making it ideal for optical components and transparent injection-molded parts. Its visible light transmittance reaches up to 92%, far exceeding most engineering plastics. Moreover, PMMA can be polished to achieve glass-like clarity.

- High Transparency: An ideal substitute for glass in lighting and display applications.

- Excellent Refractive Index: Enhances uniform light distribution and visual performance.

- Brilliant Surface Gloss: Produces a premium look after molding and polishing.

- Stable Weatherability: Maintains clarity over long-term use.

✨ PMMA’s optical excellence makes it the ideal “transparent plastic.”

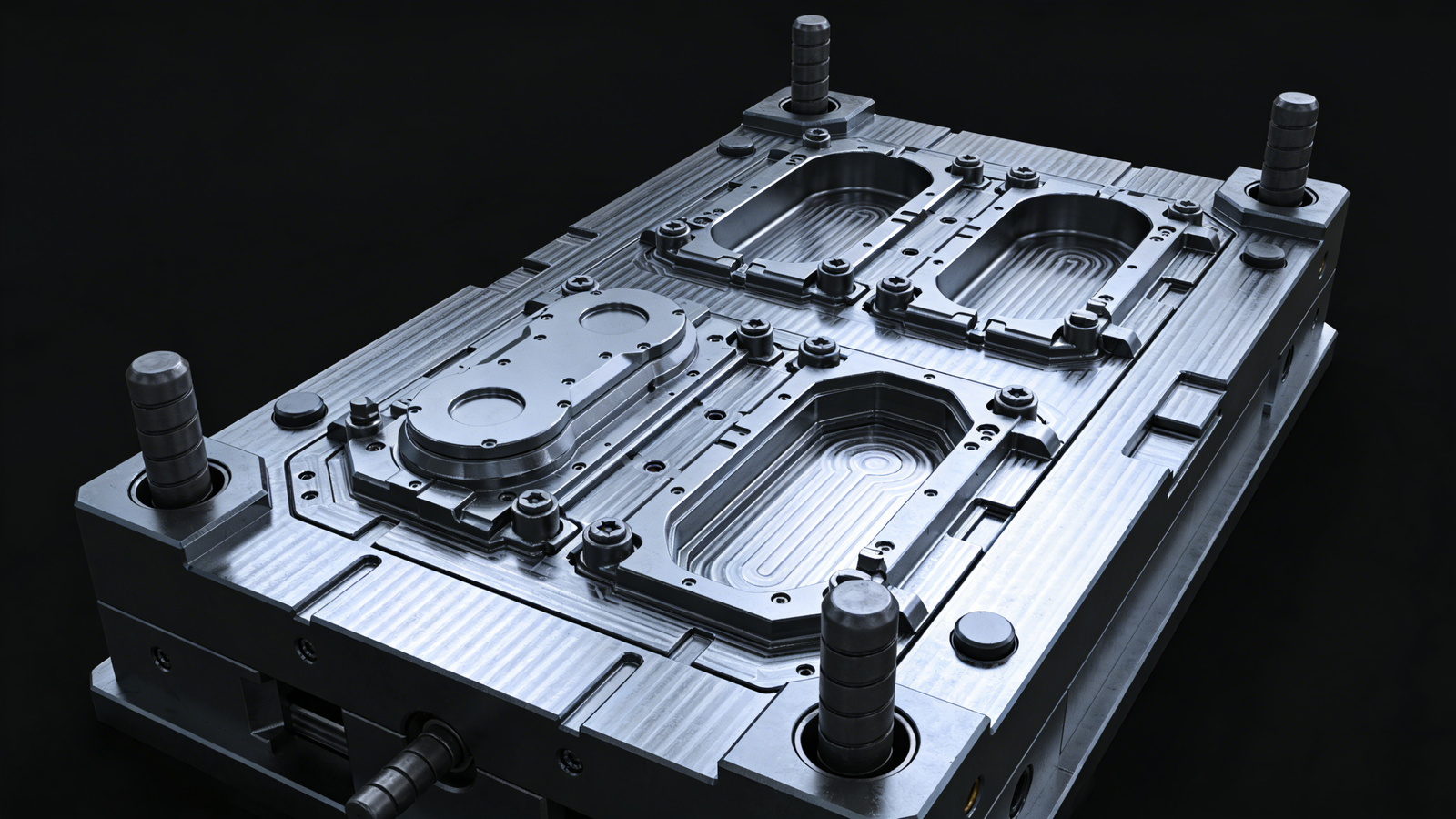

How Does PMMA Perform in Injection Molding?

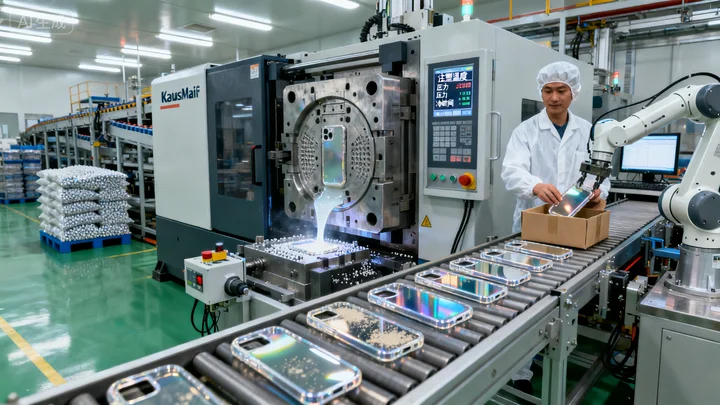

PMMA has excellent flowability, enabling it to form complex part geometries with ease. Its low shrinkage and dimensional stability ensure higher accuracy in mass production. This makes PMMA a standout material for automotive lamp covers, electronic housings, and other high-demand parts.

- Strong Flowability: Suitable for intricate injection mold designs.

- Low Shrinkage: Ensures precise geometries and reduces scrap rates.

- Superior Surface Finish: Provides gloss without additional coatings.

- Heat Stability: Minimizes deformation during molding.

⚙️ PMMA demonstrates stable and efficient molding performance.

What Value Does PMMA Bring to Applications?

PMMA is widely used in automotive, construction, medical, and consumer product fields. It delivers not only an appealing transparent look but also combines safety and durability. Its lightweight nature offers a more economical and efficient alternative to traditional glass.

- Automotive Headlamps: High transparency ensures clear nighttime illumination.

- Architectural Skylights: Provides safe and lightweight daylighting solutions.

- Medical Device Housings: Combines non-toxicity with visibility.

- Consumer Product Surfaces: Enhances premium appearance.

🚗 PMMA applications not only meet functional needs but also add market value.

Comparative Advantages of PMMA in Injection Molding

| Property | PMMA | PC | ABS | PS |

|---|---|---|---|---|

| Transparency | Excellent | High | Moderate | High |

| Weatherability | Outstanding | Good | Average | Poor |

| Dimensional Accuracy | High | Moderate | High | Average |

| Surface Gloss | Superior | Good | Moderate | Superior |

Want to explore more about PMMA’s commercial potential in injection molding? Reach out today via contact us for customized solutions!

Expansion

PMMA is not only the “Queen of Plastics” but also a key material driving industry upgrades. Its lightweight, clarity, and durability are gaining increasing attention across manufacturing. From next-generation smart lighting to high-end consumer housings, PMMA offers vast potential.

1.Automotive Industry: Meets lightweight and safety needs.

2.Construction Sector: Enhances aesthetics and daylighting.

3.Medical Devices: Ensures reliability and non-toxicity.

4.Consumer Products: Creates greater added market value.

Conclusion

In summary, PMMA has become the industry’s recognized “Queen of Plastics” due to its optical advantages, injection molding performance, and versatile applications. It not only represents the peak of material performance but also the trend of future manufacturing. With commercial demand driving growth, PMMA will continue to empower enterprises with value and competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!