LDPE is widely used in injection molded products due to its flexibility and chemical resistance, but some finished parts may have an unpleasant oily touch. Manufacturers often treat this as a quality concern, as it may indicate formulation or process deficiencies. In competitive markets, surface feel directly impacts brand perception and customer retention.

Oil film formation is typically caused by the migration of low-molecular-weight components or slip agents to the surface, highly influenced by resin purity, processing temperature, and storage conditions. When these factors are precisely managed, what was a problem can become a competitive advantage. With systematic optimization of formulation and processing, businesses can not only improve tactile feel but expand product value.

What causes the greasy feel on some LDPE surfaces?

During injection molding, shear heat activates low-molecular-weight fractions in LDPE, which are more likely to migrate to the surface. Excess use of slip or anti-block agents in the formula can create a visible oil film. If mold temperature is high and cooling insufficient, the migration is intensified, deteriorating surface quality. Environmental factors like heat and humidity further accelerate the oily effect.

- Resin Purity: High LMW content leads to faster surface bloom.

- Mold Temperature Management: Elevated mold temp drives additives to the surface.

- Formulation Balance: Excess slip agent often results in residual film.

- Storage Aging: Prolonged stacking allows more LMW components to accumulate on surface.

How can process optimization reduce surface oiliness?

Reducing melt residence time at high temperatures minimizes the activation of low-molecular fractions. Optimizing screw shear and back pressure enhances dispersion and suppresses additive clustering. Fast and uniform cooling freezes molecular movement, preventing oil film at the source. Real-time monitoring also allows for immediate adjustments in the process window.

- Screw Shear: Improves mixing and lowers unbound molecules.

- Cooling Design: Stronger cooling flow reduces additive migration.

- Surface Texture: Matte textures can mask any slight oil residue.

- In-line Monitoring: Infrared sensors detect film thickness and adjust parameters.

How to leverage LDPE's oiliness for commercial value?

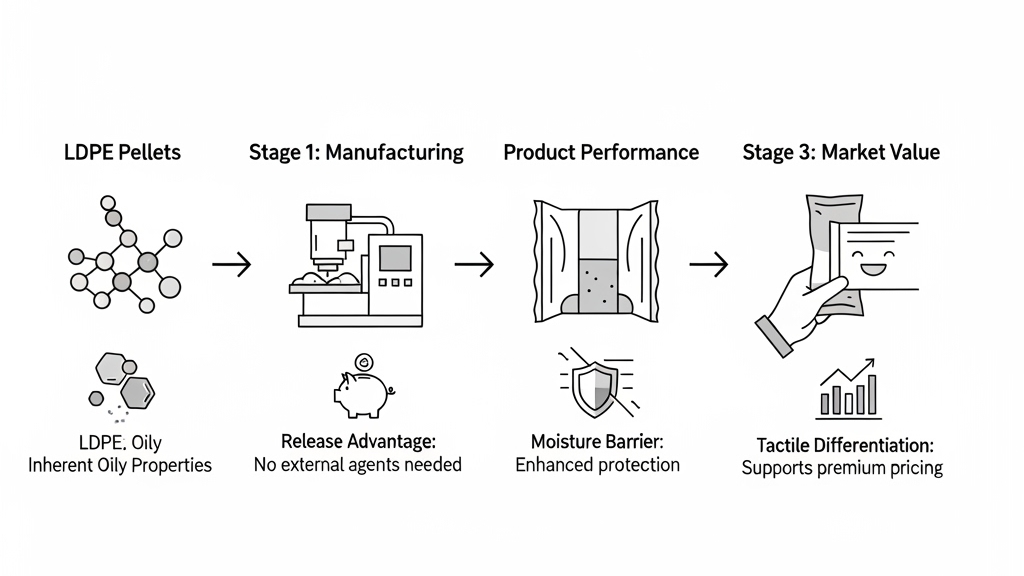

While oiliness is typically undesired, in some functional applications, surface oil films act as natural release layers or moisture barriers. Packaging manufacturers often use this feature to reduce coating steps and improve production efficiency. With controlled oil layer thickness, companies can craft premium tactile experiences and capture niche high-end markets. Partnering with additive suppliers enhances customization and strengthens market positioning.

- Release Advantage: Built-in oil film can eliminate mold release agents.

- Moisture Barrier: Oiliness enhances humidity resistance in packaging.

- Tactile Differentiation: Unique feel supports premium pricing strategies.

- Additive Co-development: Joint R&D expands application boundaries.

Comparison Table: LDPE Oiliness Causes & Solutions

| Factor | Resin Purity | Excess Additives | High Mold Temp | Long-Term Storage |

|---|---|---|---|---|

| Root Cause | LMW migration | Slip agent surface bloom | Additive activation | LMW accumulation |

| Fix Strategy | Lower LMW | Optimize additive ratio | Lower temp | Vacuum packaging |

| Business Impact | Slight cost rise | Better stability | Longer cycle | Inventory pressure |

| Application Fit | Food wrap | Industrial film | Appliance housing | Warehouse logistics |

Highlights

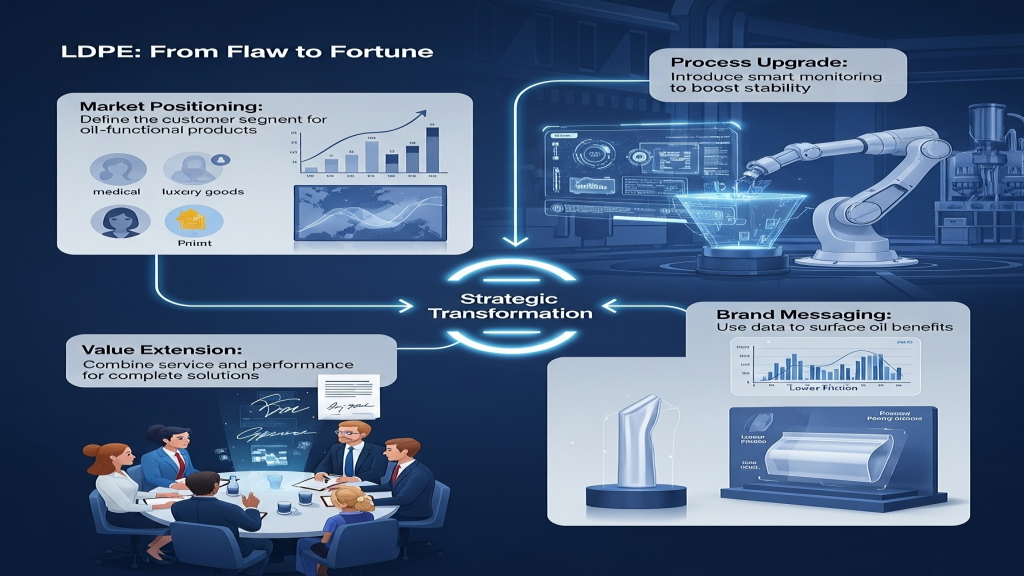

In a competitive materials landscape, mastering oil control in LDPE can increase value per unit. Through digital process monitoring, manufacturers can turn downsides into marketable features. Once surface oiliness is seen as functional, it becomes a strategic differentiation point. By aligning quality management with market trends, companies can set higher entry thresholds.

1.Market Positioning: Define oil-functional product’s customer segment.

2.Process Upgrade: Introduce smart monitoring to boost stability.

3.Brand Messaging: Use data to prove surface oil benefits.

4.Value Extension: Combine service and performance for complete solutions.

Conclusion

Oiliness is not inherently a defect but a controllable and usable trait. By refining formulation, process, and storage, businesses can improve surface quality while increasing product value. Transforming pain points into product features opens up new profit paths. Data-driven injection molding strategies will continue to align LDPE properties with evolving market demands.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!