Introduction

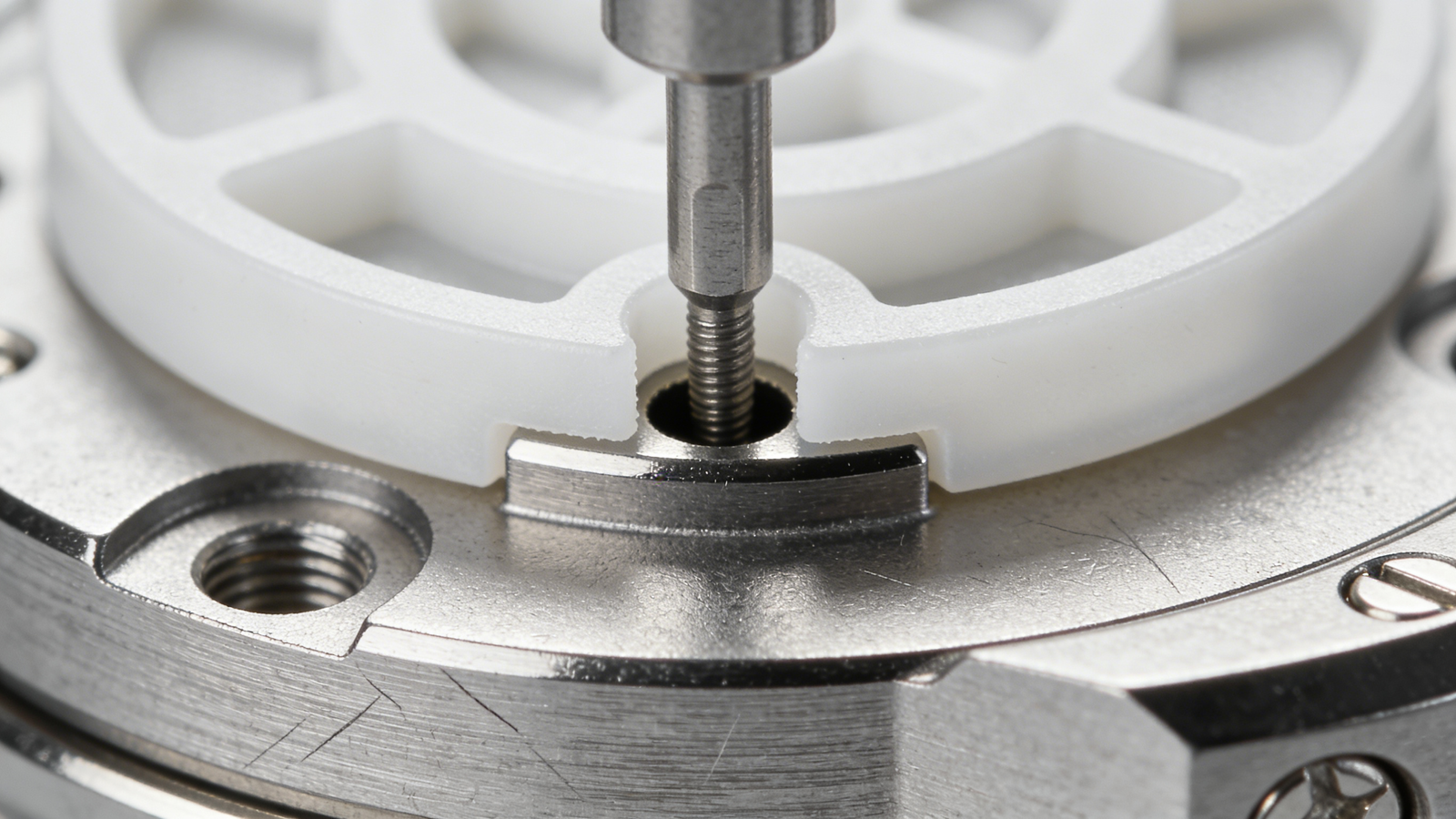

Watch components demand extremely high standards for dimensional accuracy, tolerance control, and assembly stability, far beyond those of conventional industrial parts. From Xiamen Ruicheng’s long-term experience serving watch and precision structural component manufacturers, precision deviation is rarely caused by a single molding step but by the compounded effects of material behavior, mold design, and metal machining quality.

In high-end and functional watches, plastic injection parts are frequently assembled together with metal components, which significantly amplifies even minor dimensional deviations. Only by tracing injection issues back to metal processing and mold manufacturing can long-term precision stability be truly achieved.

Why Do Watch Injection Parts Easily Lose Dimensional Control?

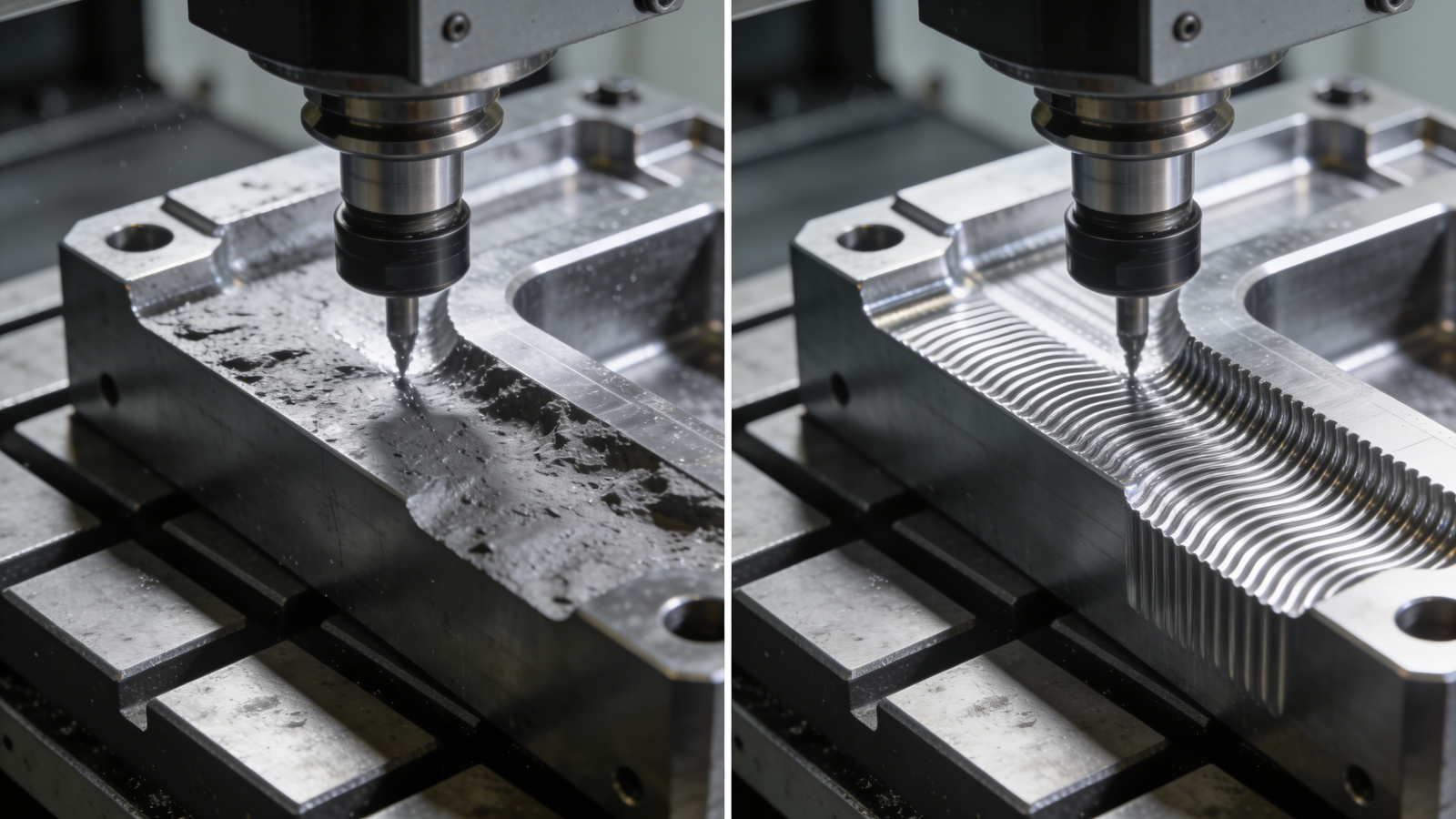

Dimensional instability in watch injection parts is most often caused by mismatches between mold structure design and metal machining accuracy, a problem that becomes more severe in micro-sized components. Based on Xiamen Ruicheng’s project audits, when cavities are produced using conventional CNC machining without precision-oriented mold manufacturing strategies, microscopic errors are continuously amplified by material shrinkage. Dimensional deviation is not primarily an injection parameter issue, but a consequence of metal machining precision failing to align with the final tolerance target.

Cavity consistency: Multi-cavity molds processed with inconsistent machining paths introduce systematic size variations.

Thermal deformation: Localized heat from high-speed cutting leaves irreversible micro-deformation in mold cores.

Lack of compensation logic: Without shrinkage compensation embedded in CNC programming, deviations directly transfer to molded parts.

Broken inspection loop: Absence of in-process measurement prevents early correction of machining errors.

🔎 Precision issues often originate from the very first metal cutting operation.

How Does Mold Metal Processing Affect Assembly Accuracy?

In watch components, injection-molded parts must precisely interface with cases, shafts, and metal brackets, imposing strict requirements on mold metal processing. Xiamen Ruicheng’s comparative studies show that assembly pass rates differ significantly between precision metal cutting solutions and conventional approaches, especially in micro-holes and thin-wall areas. Unstable assembly accuracy is fundamentally caused by machining tolerances that are not aligned with the assembly system.

Mating surface refinement: Critical assembly areas require secondary precision finishing to ensure surface uniformity.

Toolpath optimization: Different cutting tools and feed strategies for different regions reduce geometric deviation.

Unified datum principle: Mold machining and inspection must reference the same datum system.

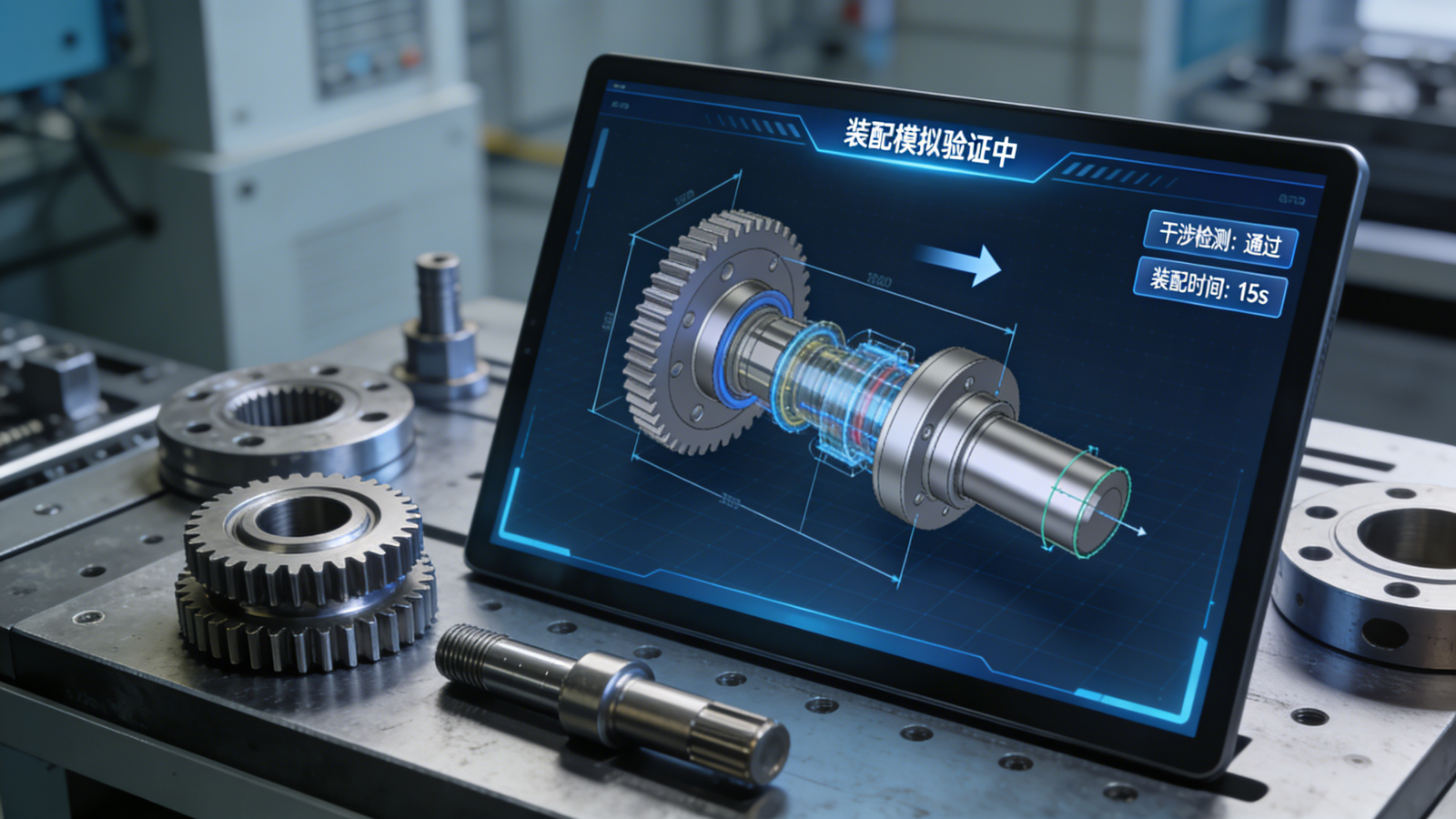

Collaborative validation: Assembly simulation immediately after metal processing reveals risks early.

⚙️ Assembly problems are often already written into the mold’s metal cutting path.

How Can Injection Stability Be Improved Through Metal Processing Systems?

Improving injection stability is not about endlessly adjusting molding parameters but about restructuring control logic from the metal processing system. In watch-related projects, Xiamen Ruicheng implemented a precision-engineering-centered workflow based on precision engineering principles, combined with forward-shifted quality control checkpoints, achieving significant improvements in batch consistency. Once metal processing becomes stable, injection molding outcomes become predictable.

Machining rhythm control: Standardized processing cycles reduce operator-induced variability.

Embedded in-process inspection: Measurement steps are integrated into machining rather than left to final inspection.

Material batch management: Different steel batches are matched with dedicated parameter libraries.

Process data accumulation: Historical machining data becomes a reliable reference for new projects.

📈 Stable injection results are built on a stable metal processing foundation.

Key Comparison Dimensions for Watch Injection Precision

| Dimension | Conventional Approach | Precision Processing Approach | Risk Difference | Cost Impact |

|---|---|---|---|---|

| Cavity machining | Standard CNC | High-precision CNC + finishing | Dimensional drift | Medium |

| Datum control | Multiple datums | Unified datum | Assembly deviation | Low |

| Inspection method | Final inspection | In-process inspection | Batch instability | Medium |

| Data traceability | None | Full-process records | Hard to trace issues | Low |

To explore how Xiamen Ruicheng builds long-term precision control models for watch injection components through metal processing systems, feel free to contact us

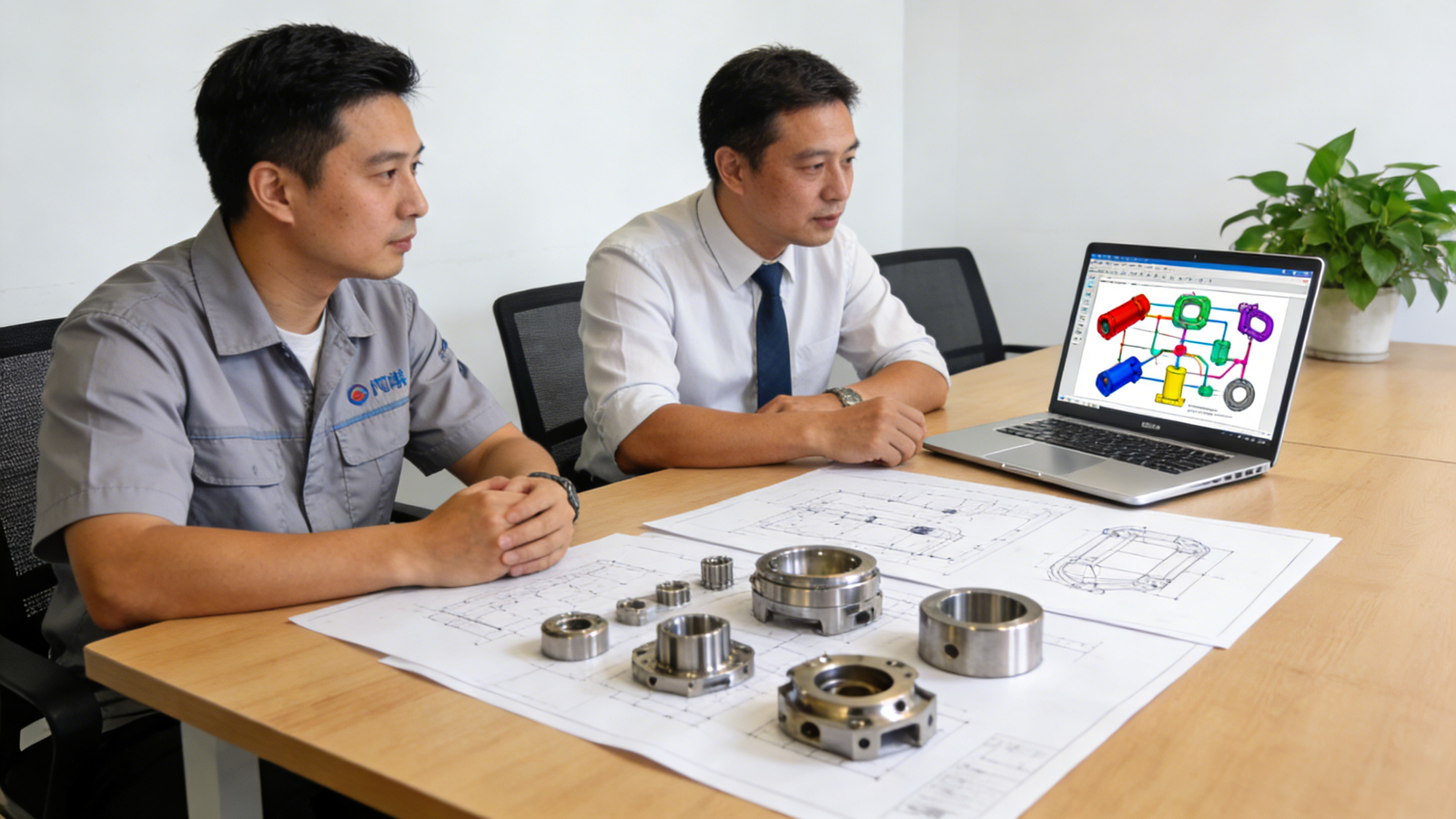

From Processing to Decision-Oriented Precision Partnership

Xiamen Ruicheng does not position itself merely as a machining supplier, but as a long-term precision decision partner. During the early development stage of watch components, we simultaneously evaluate injection structures and metal processing feasibility to avoid repeated corrections later. This forward-involvement model allows customers to clearly understand precision boundaries and risks before mass production.

1.Requirement translation: Converting assembly goals into executable machining metrics.

2.Process co-development: Joint confirmation of metal processing and injection strategies.

3.Prototype validation: Small-batch trials to verify stability assumptions.

4.Mass production accompaniment: Continuous optimization rather than one-time delivery.

FAQ – Procurement-Oriented Decision Questions

Question 1: What are the core advantages of Xiamen Ruicheng’s watch precision injection and metal processing services?

Answer: Xiamen Ruicheng focuses on mold metal processing as the primary control point, defines critical dimensional zones, and ensures precision stability through in-process inspection and data traceability, directly supporting buyers’ long-term consistency requirements.

Question 2: What information should we provide to quickly initiate evaluation and quotation?

Answer: We recommend submitting complete structural drawings, assembly relationships, and target tolerance requirements through our designated channels. Xiamen Ruicheng typically provides an initial feasibility analysis within 12 hours.

Question 3: How are MOQ and lead time managed for different order volumes?

Answer: Small-batch trials are supported during validation stages, while mass production orders are assigned dedicated machining capacity with flexible scheduling to handle demand fluctuations.

Question 4: How are quality or assembly issues handled after delivery?

Answer: Xiamen Ruicheng operates a rapid issue evaluation mechanism, completing root-cause analysis within 48 hours and implementing corrective or replacement solutions when necessary.

Question 5: Can customized solutions be provided for special structures or applications?

Answer: Yes, customized processing and inspection strategies are developed based on specific structures and usage conditions, with transparent timelines and cost implications defined during the proposal stage.

Conclusion

Insufficient injection precision in watch components is not an isolated molding issue, but the combined result of metal processing quality, mold manufacturing discipline, and decision logic. By shifting precision control upstream to the metal processing stage, Xiamen Ruicheng helps customers establish predictable and controllable quality systems before mass production. When the processing system is stable, injection precision becomes a natural outcome rather than a risk. This is the true value of moving from product display to decision partnership.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!