Introduction

The stable performance of ABS pipe fittings is not a coincidence but the result of strict material selection and process control. Every production stage ensures long-term reliability of the product. By focusing on material purity and formula design, we achieve a balance between strength, toughness, and durability.

During production, we apply precise process monitoring and quality inspection to avoid common defects. This ensures our ABS pipe fittings maintain consistency and reliability in applications. As a result, stability has become a key reason customers choose our solutions.

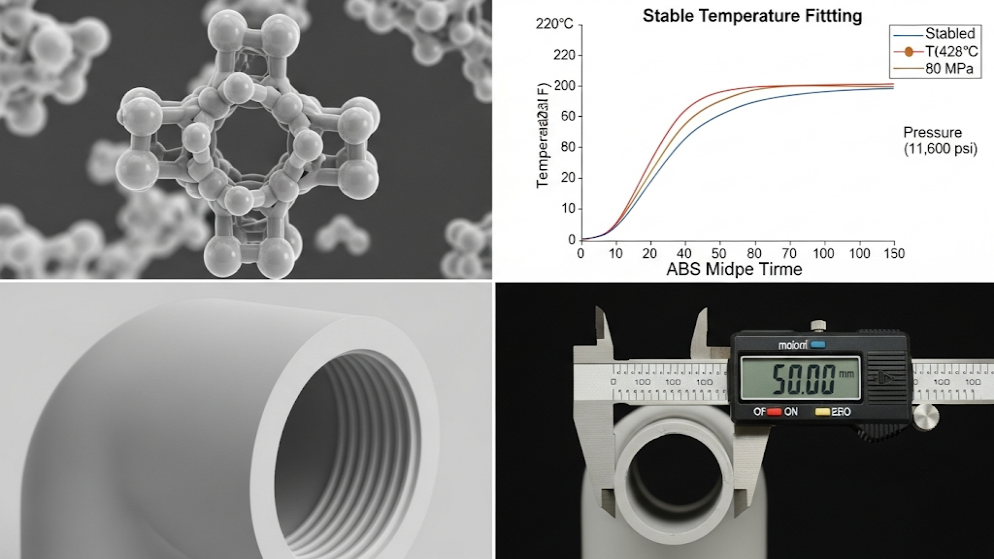

Why can ABS pipe fittings remain stable over time?

The long-term stability of ABS pipe fittings relies on both optimized formulation and controlled molding processes. By implementing strict injection temperature and parameter control, internal stress is significantly reduced. This ensures the fittings do not easily crack or deform during long-term use, enhancing product lifespan.

- Material Uniformity: Optimized formula ensures balanced molecular distribution.

- Process Precision: Accurate temperature control minimizes internal stress.

- Surface Smoothness: Smooth finish reduces friction and wear.

- Structural Stability: Uniform molding provides dimensional integrity.

😊 This section emphasizes how we ensure the long-term stability of ABS pipe fittings through formula and process control.

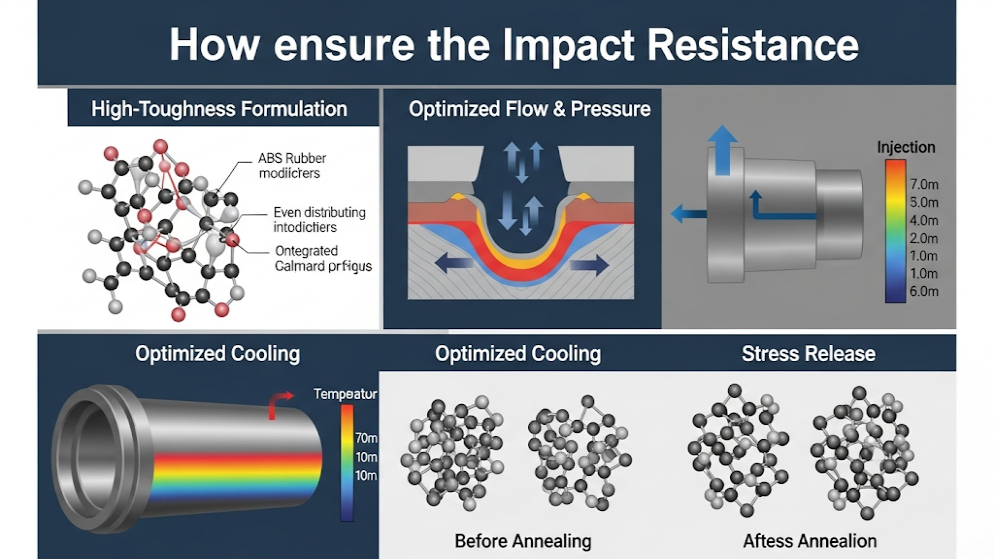

How do we ensure the impact resistance of ABS pipe fittings?

The impact resistance of ABS fittings is not only based on material properties but also relies on process synergy. By optimizing flow channel design and injection pressure control, material distribution becomes more uniform. This ensures the fittings resist fracture or deformation under stress.

- High Toughness Formula: Additives improve impact resistance.

- Optimized Cooling: Scientific cooling avoids local brittleness.

- Pressure Balance: Balanced injection prevents weak points.

- Stress Release: Minimizes risks from molecular orientation.

💡 This section highlights how we achieve strong impact resistance for ABS pipe fittings through formulation and process optimization.

How do our ABS pipe fittings avoid deformation?

During injection molding, shape retention depends on precise flow and cooling control. Through mold design and balanced cooling, ABS fittings effectively reduce warpage and shrinkage. This ensures dimensional accuracy and assembly compatibility.

- Mold Optimization: Well-designed flow channels ensure uniform material flow.

- Balanced Cooling: Even temperature distribution prevents warpage.

- Material Control: Stable molecular chain arrangement is maintained.

- Structural Reinforcement: Consistent wall thickness minimizes stress.

🔧 This section explains how mold and process control help our ABS pipe fittings avoid deformation.

Comparative Advantages of ABS Pipe Fittings

| Performance Index | Our ABS Fittings | Standard ABS Fittings | Low-End ABS Fittings | Metal Alternatives |

|---|---|---|---|---|

| Impact Resistance | High | Medium | Low | High |

| Dimensional Stability | Excellent | Medium | Poor | Excellent |

| Cost Efficiency | High | Medium | High | Low |

| Service Life | Long | Medium | Short | Long |

Extended Applications

ABS pipe fittings are not only suitable for residential and industrial water systems but also extend to chemical, HVAC, and construction projects. Their proven stability ensures reliable performance across multiple environments. By offering customized solutions, we help customers meet demanding engineering requirements.Our ABS fittings can also replace certain metal parts, reducing weight and lowering maintenance costs. This advantage enhances the overall efficiency of customer projects.

1.Engineering Adaptability: Supports applications across industries.

2.Customer Customization: Tailored solutions for specific needs.

3.Cost Reduction: Lightweight alternatives save resources.

4.Durability Validation: Proven through long-term applications.

Conclusion

Through material optimization, precise process control, and mold design, we ensure superior stability, impact resistance, and deformation prevention for our ABS pipe fittings. This end-to-end quality assurance makes our products exceptionally reliable in the market. With these advantages, we not only earn customer trust but also expand into broader application fields.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!