Introduction

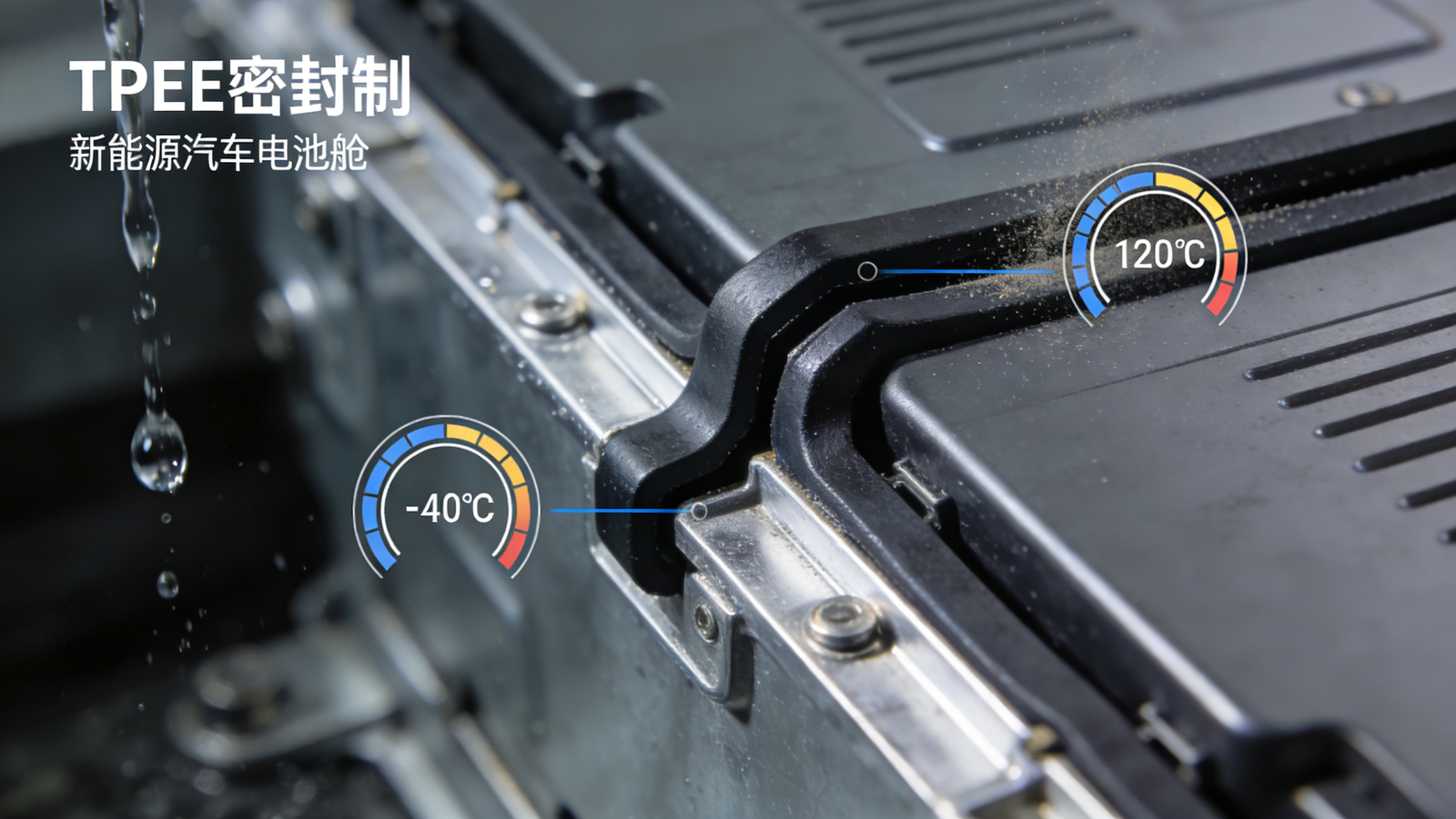

In automotive sealing systems, long-term cyclic stretching, compression, and deformation are among the primary causes of seal failure, and material selection combined with processing methods ultimately defines product lifespan. High-strength TPEE injection molded automotive seals are increasingly replacing traditional rubber solutions and becoming a strategic focus for OEMs and Tier 1 suppliers.

From Xiamen Ruicheng’s mass-production experience, seal durability is not determined by material properties alone, but by the combined effects of material formulation, injection molding processes, and structural design. Only by fully understanding TPEE fatigue behavior during injection molding can long-term sealing risks be effectively reduced.

How Does TPEE Molecular Structure Improve Tensile Fatigue Resistance in Automotive Seals?

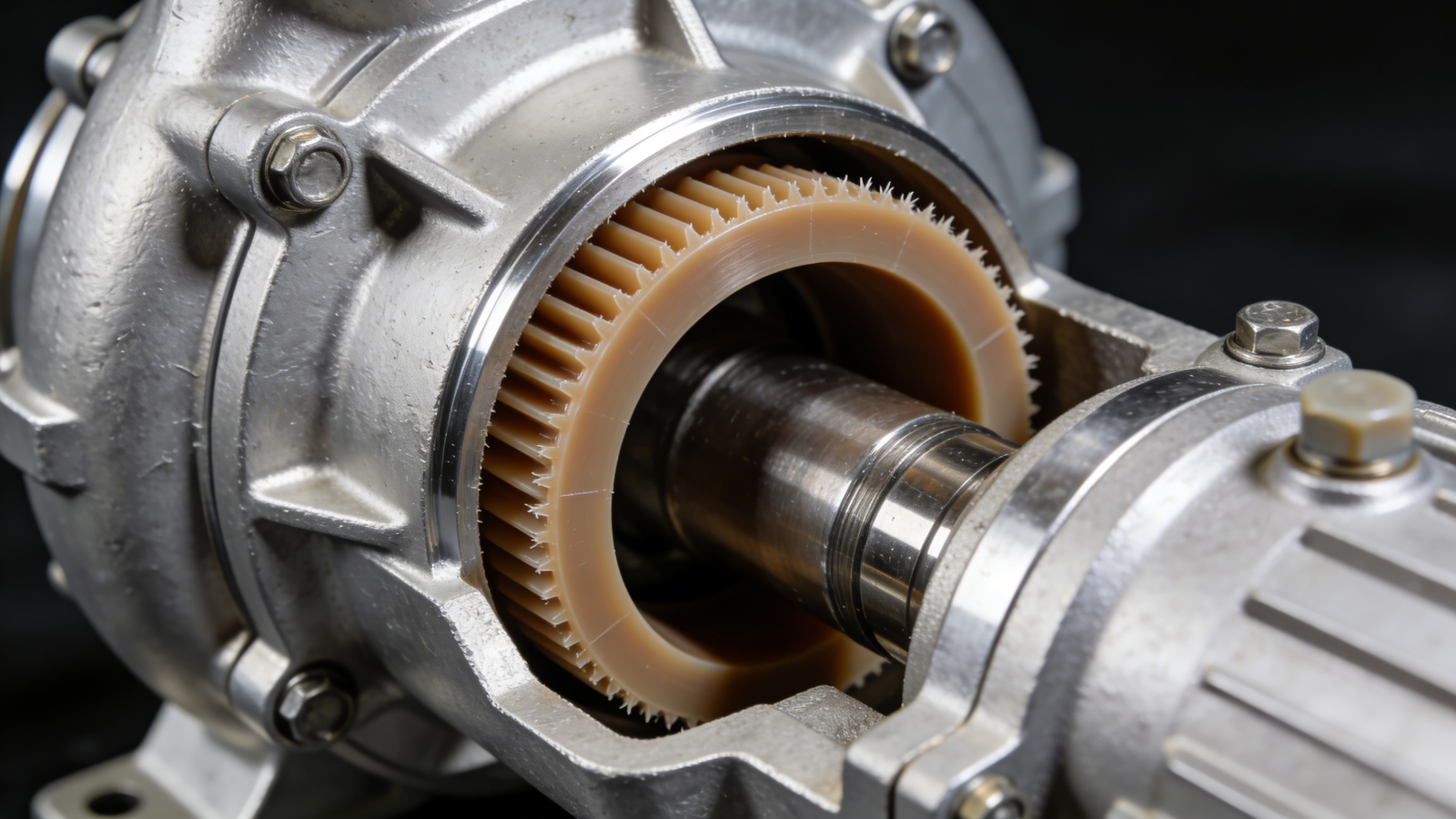

TPEE is an engineering-grade thermoplastic elastomer that integrates rigidity and elasticity, with hard and soft molecular segments working synergistically to maintain elastic recovery under repeated tensile loads. This structural advantage is further amplified through injection molding, allowing automotive seals to withstand high-frequency deformation without permanent set. In real-world applications, the combination of TPEE material properties and automotive sealing systems delivers significantly extended fatigue life in dynamic areas such as doors and sunroofs.

Segment synergy: Hard segments provide tensile strength and tear resistance under repeated stretching.

Elastic recovery: Soft segments ensure rapid rebound after unloading, minimizing stress accumulation.

Energy dissipation: Internal molecular motion disperses cyclic energy, delaying crack initiation.

Environmental stability: Mechanical performance remains consistent across temperature and humidity variations.

🔧 This molecular balance is the fundamental reason TPEE performs reliably under repeated tensile fatigue.

What Role Does Injection Molding Play in Enhancing Fatigue Resistance?

Compared with extrusion or vulcanization, injection molding enables precise control of melt flow, orientation, and cooling behavior in TPEE components. Xiamen Ruicheng has observed that optimized injection parameters significantly reduce early-stage fatigue failures in automotive seals. Through continuous refinement of injection molding control and the TPEE processing window, seal consistency and durability are maintained in high-volume production.

Melt flow balance: Controlled flow paths prevent excessive molecular orientation and stress concentration.

Cooling uniformity: Even cooling reduces residual stress, improving cyclic fatigue endurance.

Tooling precision: High-accuracy molds ensure uniform wall thickness and eliminate weak fatigue zones.

Process repeatability: Stable parameters guarantee consistent fatigue performance across production batches.

⚙️ In fatigue-sensitive applications, process stability often outweighs nominal material specifications.

How Does Structural Design Further Amplify TPEE Fatigue Performance?

In automotive sealing applications, component geometry often determines whether material properties can be fully utilized. At Xiamen Ruicheng, cross-section optimization and stress-distribution design during injection molding allow TPEE’s fatigue resistance to translate into measurable service-life gains. By integrating seal structure design with fatigue life analysis, failure risks under real operating conditions are significantly reduced.

Stress distribution: Optimized cross-sections minimize localized tensile peaks.

Dynamic compliance: Controlled flexibility allows micro-movement without rigid overextension.

Assembly tolerance: Seals maintain performance even under installation variation.

Long-term durability: Structural and material synergy extends overall vehicle service life.

🚗 Effective design ensures that material advantages are fully realized in real-world use.

Comparison of Tensile Fatigue Performance Across Automotive Seal Materials

| Comparison Factor | TPEE Injection Seal | EPDM Rubber | TPU Seal | PVC Seal |

|---|---|---|---|---|

| Tensile fatigue life | High | Medium | Medium-High | Low |

| Shape recovery | Excellent | Good | Good | Fair |

| Injection consistency | High | Low | Medium | High |

| Operating temperature range | Wide | Medium | Medium | Narrow |

If you are evaluating long-term seal reliability, this comparison is only a starting point. Selecting the right solution requires alignment with your vehicle platform and operating conditions—feel free to contact us.

Key Considerations from Material Selection to Mass Production

In automotive seal programs, procurement decisions go beyond material choice and focus on supplier capability and risk management. Xiamen Ruicheng supports customers from early sampling through process validation to full-scale production, helping reduce development uncertainty. High-strength TPEE injection solutions balance durability requirements with controlled cost and scalable manufacturing.

1.Requirement clarification: Define tensile frequency, environmental exposure, and lifetime targets.

2.Solution validation: Verify fatigue performance through prototype and testing.

3.Process locking: Fix injection parameters to ensure mass-production consistency.

4.Ongoing support: Provide continuous quality and process monitoring during production.

FAQ

Question 1: What is the core advantage of Xiamen Ruicheng’s high-strength TPEE injection molded automotive seals?

Answer: Our solution is built around stable tensile fatigue resistance, combining material selection, injection process control, and structural design to ensure long-term sealing reliability under dynamic conditions.

Question 2: What information is required to quickly receive a quotation and technical proposal?

Answer: Providing cross-section drawings, application location, expected service life, and annual volume allows Xiamen Ruicheng to deliver a production-ready injection molding solution and quotation efficiently.

Question 3: How are lead times managed for different order volumes?

Answer: Rapid prototyping supports small-batch validation, while stabilized production lines ensure reliable delivery schedules for mass production.

Question 4: How are quality or delivery issues handled after procurement?

Answer: Xiamen Ruicheng operates a clear quality evaluation and feedback mechanism, ensuring timely investigation and corrective action.

Question 5: Can seals be customized for special vehicle platforms or operating conditions?

Answer: Yes, customization is supported based on temperature range, tensile frequency, and installation requirements, provided detailed operating data is supplied.

Conclusion

The superior tensile fatigue resistance of high-strength TPEE injection molded automotive seals results from the combined optimization of material structure, injection molding processes, and component design. Based on Xiamen Ruicheng’s practical experience, early involvement in injection molding decisions is critical to minimizing long-term failure risk. For automotive programs demanding durable and predictable performance, a decision-partner approach delivers measurable value.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!