Short shots in injection molding occur when the mold cavity is not completely filled with molten plastic. This defect can lead to incomplete parts, weak structural integrity, and ultimately, production delays. To prevent short shots in injection molding, optimize mold design, adjust processing parameters, and ensure proper material handling. By addressing these factors, you can achieve consistent, high-quality molded parts.

Let’s explore what causes short shots and how to eliminate them.

What Causes Short Shots in Injection Molding?

Short shots happen when there’s insufficient molten plastic to completely fill the mold cavity. This can be caused by inadequate material flow, improper venting, low injection pressure, or inconsistent material temperatures. These issues prevent the molten plastic from reaching all areas of the mold, especially in thin or complex sections.

Imagine trying to pour syrup into a mold but stopping halfway—it won’t fill all the corners or edges, leaving gaps. In injection molding, similar gaps appear when conditions aren’t optimized.

How to Prevent Short Shots?

Optimize Mold Design

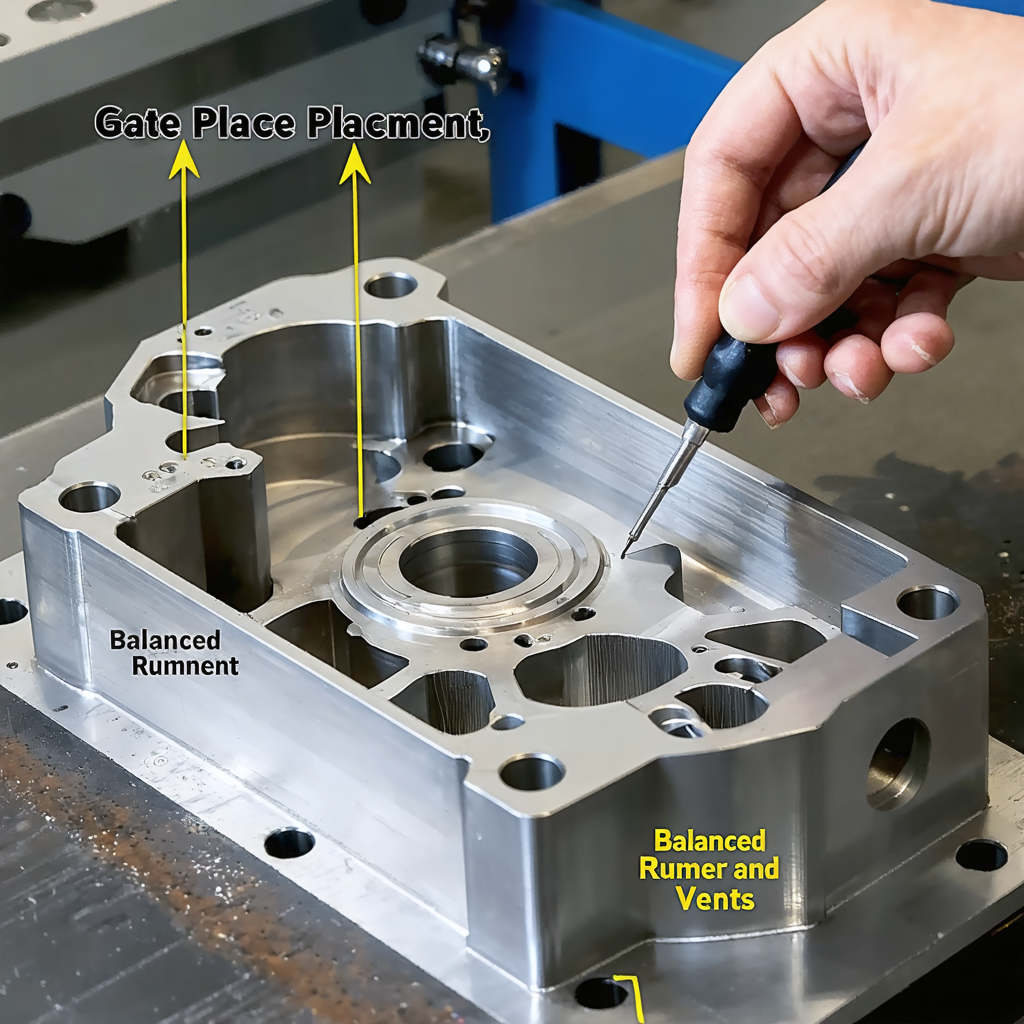

A well-designed mold ensures uniform material flow and minimizes the risk of short shots.

- Proper Gate Placement: Position gates close to thick or hard-to-fill sections to improve flow distribution.

- Use Balanced Runners: Balanced runner systems ensure equal flow to all mold cavities.

- Add Venting: Include vents to release trapped air, allowing the molten plastic to fill the entire cavity.

Adjust Processing Parameters

Fine-tuning processing conditions can significantly reduce short shots.

- Increase Injection Pressure: Higher pressure helps push the molten plastic into all areas of the mold.

- Raise Injection Speed: Faster injection speeds ensure that the material fills the cavity before it starts to cool.

- Adjust Melt Temperature: Maintain an optimal melt temperature to improve the flowability of the plastic.

| Parameter | Effect on Short Shots | Suggested Adjustment |

|---|---|---|

| Injection Pressure | Fills hard-to-reach areas | Increase gradually |

| Injection Speed | Reduces premature cooling | Increase slightly |

| Melt Temperature | Improves material flow | Raise within safe limits |

Use the Right Material

Material properties, such as viscosity and flowability, play a critical role in preventing short shots.

- Low-Viscosity Resins: These materials flow more easily into tight or thin sections of the mold.

- Dry Materials Thoroughly: Excess moisture can cause poor flow and uneven filling, increasing the risk of short shots.

- Reinforced Materials: For structural parts, use materials with consistent flow properties, such as glass-filled plastics.

Maintain Proper Machine Setup

Ensuring the injection molding machine is correctly set up prevents short shots caused by equipment issues.

- Check Screw and Barrel: Wear and tear on the screw and barrel can reduce material flow efficiency.

- Use a Larger Shot Size: If the shot size is too small for the mold cavity, adjust to avoid incomplete filling.

- Calibrate Clamping Force: Incorrect clamping force can cause material leakage and incomplete filling.

Common Mistakes to Avoid

- Poor Venting: Without proper vents, trapped air can block material flow.

- Low Melt Temperature: Plastic that’s too cool won’t flow well, leading to short shots.

- Insufficient Injection Pressure: Low pressure prevents the material from filling complex mold geometries.

Conclusion

To prevent short shots in injection molding, focus on optimizing mold design, adjusting processing parameters, using the right materials, and maintaining proper machine setup. These strategies will help ensure complete, defect-free parts and improve production efficiency.

For expert guidance on overcoming injection molding challenges, check out our resource center or contact us. Let’s work together to create flawless, high-quality parts for your next project.