Introduction

In PVC injection molding, poor thermal stability, rough mold surfaces, or improper processing conditions often lead to sticking issues. This not only affects product appearance but also increases mold cleaning frequency and production downtime. If not resolved in time, it directly impacts production efficiency and yield.

For manufacturers, PVC sticking is not just a technical problem but also a hidden cost and delivery risk. With proper process optimization and material adjustments, production stability can be improved, and maintenance reduced. Mastering process details is the key to overcoming PVC sticking issues.

Why Does PVC Stick to Molds?

When PVC is exposed to excessive heat or high surface friction in molding, sticking issues can easily occur. This results in surface scratches, accelerated mold wear, and increased demolding difficulty.

- Mold temperature control: Excessive heat accelerates PVC degradation and sticking.

- Material modification: Lubricants or stabilizers reduce friction between melt and mold.

- Mold polishing: Smoother surfaces reduce sticking risks.

- Release agent usage: Proper application prevents excessive adhesion.

😊 Controlling process and mold conditions is the first step to reducing sticking issues.

How to Optimize Processing to Reduce Sticking?

Excessive shear rate, melt temperature, and injection pressure during processing are common causes of PVC sticking. By maintaining a stable process window, sticking risks can be significantly reduced.

- Injection pressure adjustment: Prevents excessive melt stress.

- Cooling system optimization: Uniform cooling enables faster demolding.

- Runner and gate design: Proper design improves melt flow and reduces stress.

- Screw speed control: Excess speed increases PVC degradation risks.

🔧 Stable process control is essential to improve yield rates.

How Can Mold Design Prevent PVC Sticking?

Poor mold design is another critical factor behind PVC sticking. Proper draft angles, surface coatings, and venting systems are effective in improving mold release.

- Surface chrome plating: Reduces friction and improves durability.

- Draft angle optimization: Larger draft angles make demolding smoother.

- Venting design: Allows trapped gases to escape, minimizing melt retention.

- Insert mold design: Replaceable sections reduce maintenance downtime.

🛠️ Smart mold design significantly reduces PVC sticking problems.

Comparison of PVC Sticking Solutions

| Solution | Cost | Stability | Application Range | Maintenance |

|---|---|---|---|---|

| Process control | Low | Medium | Universal | Medium |

| Material upgrade | Medium | High | Wide | Low |

| Mold polishing | Medium | Medium | General | Medium |

| Surface coating | High | High | High-end products | Low |

Choose the best-fit solution for your products and click here contact us to make your PVC molding more efficient!

Industry Lessons from PVC Sticking

PVC sticking highlights the interdependence of process, mold, and material in injection molding. Manufacturers should choose the most cost-effective approach depending on product positioning and production scale.

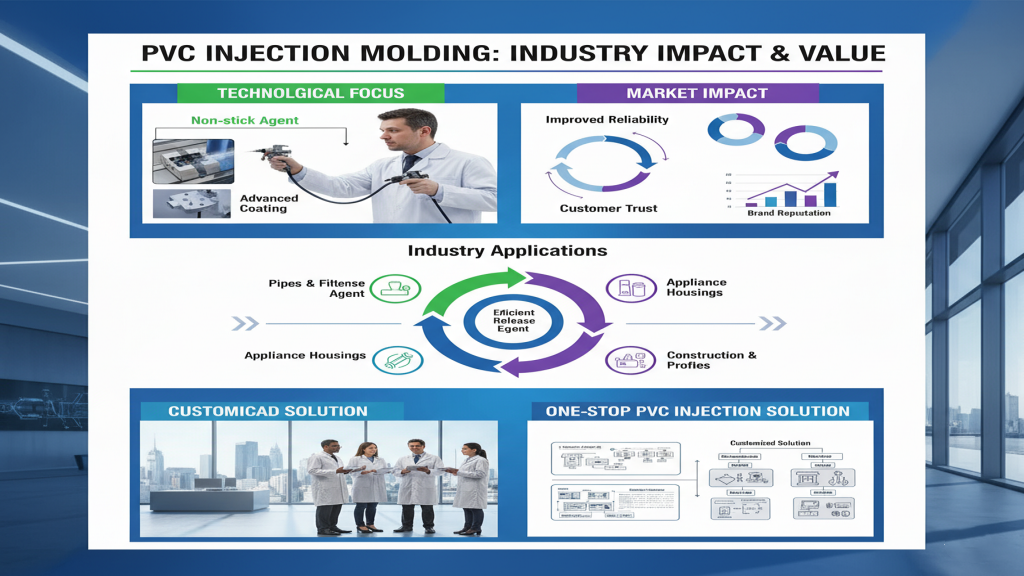

1.Industry trend: PVC is widely used in pipes, appliance housings, and construction.

2.Technology focus: Efficient release agents and advanced coatings are key innovations.

3.Market impact: Solving sticking issues enhances delivery reliability and customer trust.

4.Business value: We provide one-stop PVC injection molding solutions.

Conclusion

PVC sticking is a multidimensional challenge involving material, process, and mold factors. With proper optimization and professional solutions, manufacturers can strike the best balance between cost and efficiency. Choosing an experienced partner means higher yield and lower maintenance for your production. Our technical expertise and custom solutions are designed to keep your production stable.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!