Introduction

Vacuum casting plays a critical role in low-volume functional part development, especially as an essential tool for pre-injection molding verification. Xiamen Ruicheng assists manufacturing teams in identifying potential risks before design freeze, providing reliable data for subsequent mold investment. For procurement teams needing accelerated decisions, the quality standards of vacuum casting directly impact product fit, strength performance, and injection molding feasibility. Suppliers not only control material properties but also enforce process quality assurance to maintain consistency across batches, reducing mold trial iterations.

As product displays no longer allow customers to quickly assess supplier capabilities, vacuum casting must rely on verifiable data, stable delivery, and transparent quality processes to support decisions. For teams seeking alternatives to CNC prototypes or injection molding trials, a set of understandable, trusted, and traceable vacuum casting quality standards is key to lowering overall development risks.

How is Material Consistency Ensured?

At Xiamen Ruicheng, material consistency in vacuum casting is achieved through strict resin ratio recording, curing curve monitoring, and vacuum level control, while benchmarking against common injection molding materials to predict future production performance. Stable material consistency ensures predictability in small-batch parts’ strength and durability. Suppliers log batch numbers, curing systems, and resin data into a traceable system, referencing ISO 9001 and Material Data Sheets for validation, reducing assembly deviations caused by material fluctuation.

Data Logging: All material batches are recorded for cross-comparison.

Curing Monitoring: Temperature windows are calibrated in real time.

Resin Verification: Ensures formula matches expected mechanical properties.

Injection Material Simulation: Targeting properties close to future production parts.

🙂 Material consistency is the core metric for predicting injection molding risks.

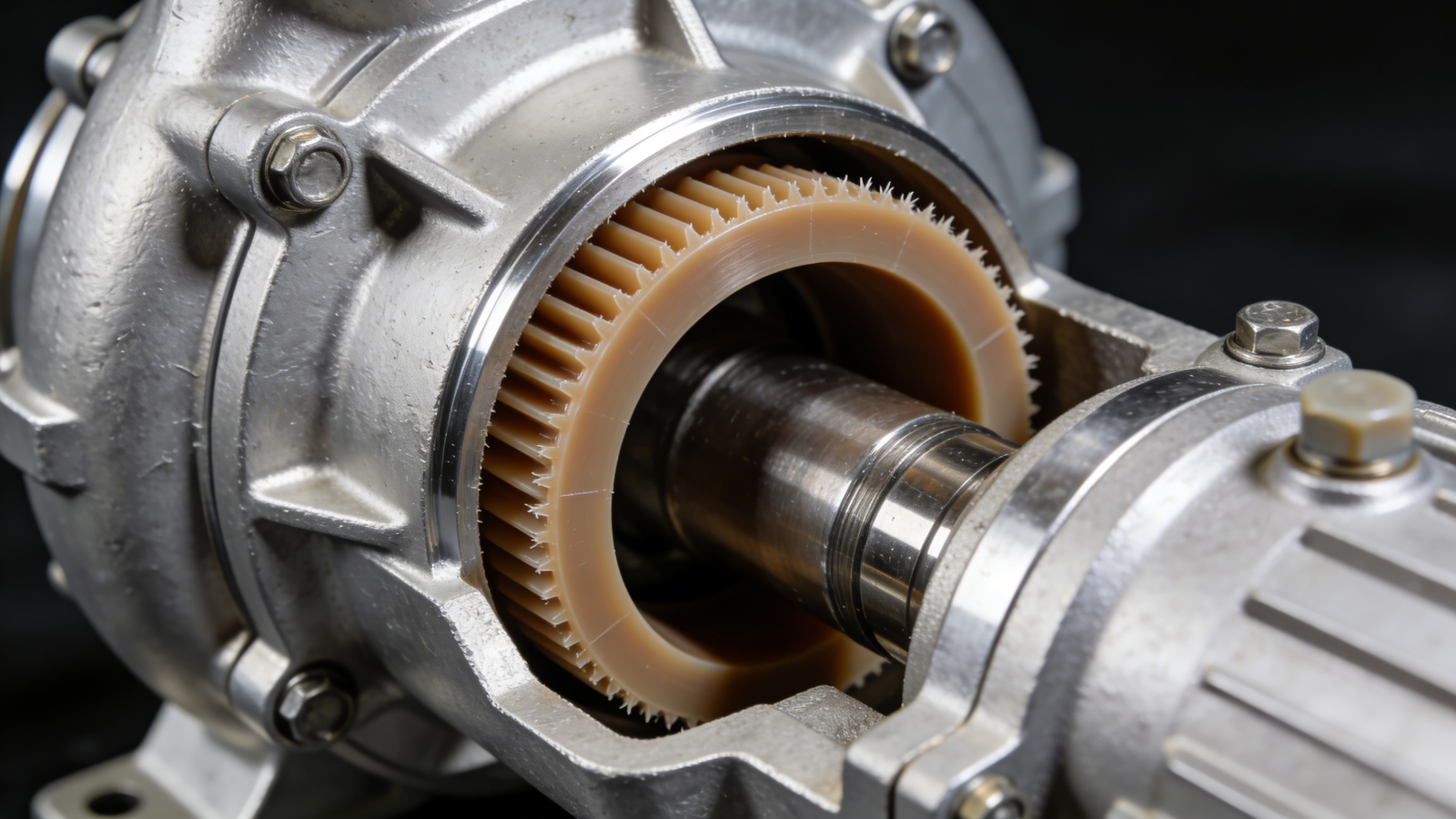

How Does the Vacuum Environment Affect Part Strength?

In vacuum casting, the cavity vacuum level determines bubble suppression and directly affects part density and structural strength, serving as a key metric of supplier capability. Xiamen Ruicheng monitors vacuum curves, mold temperature stability, and dispensing speed to achieve castings close to injection-molded density. Stable vacuum environment significantly reduces functional test failures caused by micro-voids. Engineers cross-check vacuum monitoring records with curing parameters to provide clients with realistic, reliable sample performance.

Density Enhancement: Forms the basis for improved mechanical strength.

Bubble Suppression: Reduces functional test failure rates.

Temperature Control: Prevents internal stress from local temperature differences.

Injection Equivalence Validation: Allows risk prediction before mold trials.

🚀 Vacuum stability is key to structural verification reliability.

What Standards Ensure Dimensional Stability?

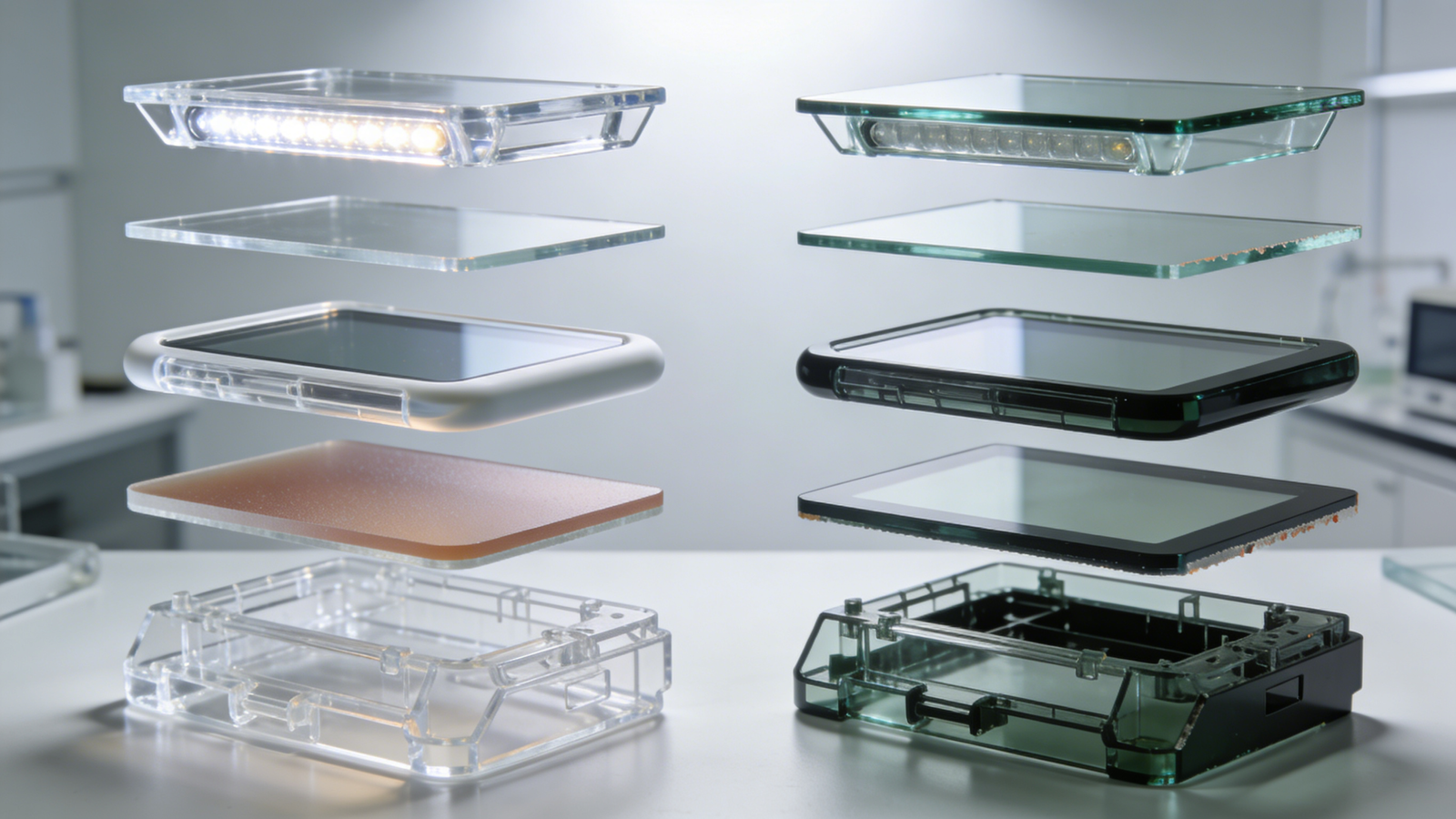

Dimensional stability is a critical indicator of whether a vacuum casting supplier has rigorous manufacturing capability, particularly for fit verification with injection parts. Xiamen Ruicheng controls dimensional deviation via standardized silicone mold processes, mold alignment structures, demolding compensation, and curing rate calibration, with CMM inspection providing clients with trustworthy small-batch data. Stable dimensions make it easier for engineering teams to predict future injection mold corrections. Suppliers follow geometric accuracy standards and CMM measurement protocols for dimension analysis, providing traceable, consistent samples.

Mold Life Management: Minimizes deviation growth over cycles.

Curing Rate Calibration: Compensates for material shrinkage.

Assembly Reference Alignment: Ensures system-level part compatibility.

Pre-trial Risk Reduction: Helps clients lower first-mold adjustment costs.

📐 Dimensional stability determines the reliability of pre-production verification.

Vacuum Casting vs Injection Verification

| Metric | Vacuum Casting | Injection Trial | Material Consistency | Delivery Time |

|---|---|---|---|---|

| Consistency | Medium | High | Controllable | Fast |

| Cost | Low | High | Stable | Medium |

| Strength | Medium-High | High | High | Stable |

| Geometric Accuracy | Medium | High | Medium-High | Medium |

Looking to identify the best process route for your project? Contact us contact us

How Vacuum Casting Reduces Decision Risks?

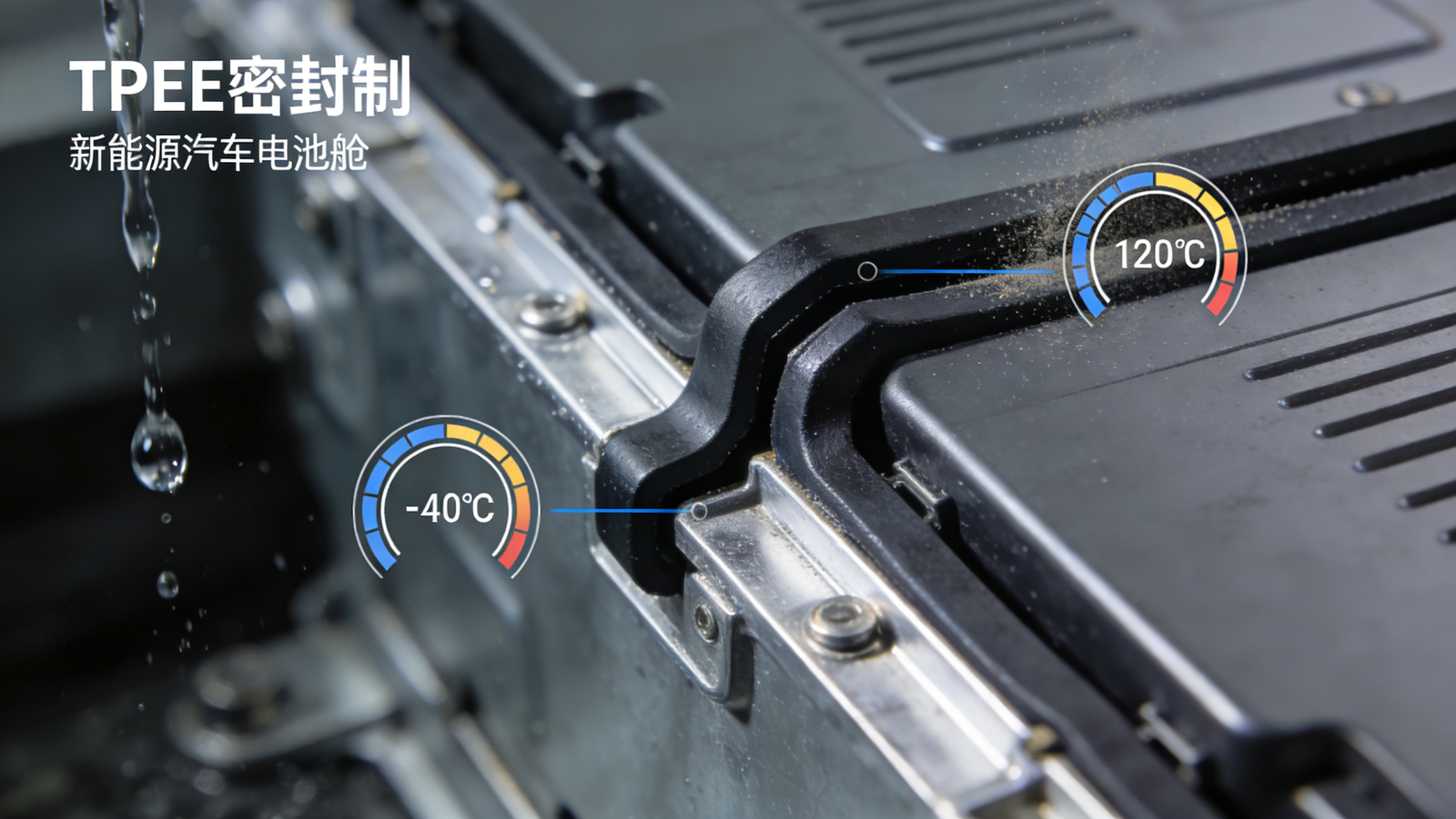

In strategic product development, vacuum casting not only serves for visual inspection but also supports system assembly, functional verification, and thermal testing, guiding mold investment decisions. It helps engineering teams filter high-risk structures, providing a controllable decision environment before mold opening. Xiamen Ruicheng offers appearance texture simulation, mechanical test parts, assembly interface validation, and batch stability records, providing customers with a fully traceable decision support system.

1.Functional Prototype Research: Confirms structural strength in real-use scenarios.

2.System Assembly Verification: Shortens cross-department confirmation cycles.

3.Injection Predictive Testing: Detects potential shrinkage or deformation issues.

4.Preemptive Risk Assessment: Reduces first-mold corrections.

FAQ

Q1: What are the core quality standards for vacuum casting?

A: Must meet controllable dimensional deviation, stable material performance, and high curing consistency with full process quality records to support functional verification.

Q2: How to connect with a vacuum casting supplier and get a quote?

A: Submit CAD/STEP files, engineers will provide manufacturability analysis and quotation within 12 hours, including free sample confirmation if needed.

Q3: What is the MOQ and delivery cycle for vacuum casting?

A: Small batch MOQ starts at 1 set, no upper limit for larger orders; typical delivery 3–7 days, complex parts expedited as needed.

Q4: What solutions do you offer if the vacuum casting parts we purchase have dimensional deviations or insufficient strength?

A: You can apply for quality verification with a CMM inspection report or functional test records within 10 working days after delivery, and you need to provide product batch information and problem details at the same time. After review and confirmation by our technical team, a solution will be given within 48 hours: free rework and recasting for dimensional deviations beyond tolerance, and full refund or replacement for insufficient strength. Meanwhile, a problem analysis report will be issued to optimize subsequent production. All vacuum casting parts come with a 3-month warranty, and free after-sales service is provided for performance issues caused by non-human factors during the warranty period.

Q5: Our products need to simulate the appearance and feel of specific materials. Can you provide customized vacuum casting services for this?

A: We fully support this. You need to provide samples or detailed parameters of the target material (such as hardness, texture, color number), as well as the CAD model of the product and description of the application scenario. We will output a material matching scheme and sample effect prediction within 3 working days, and can provide 2 free sample adjustments during the customization process before mass production. The customization cost will increase by 10%-20% according to material complexity and process difficulty, which can be confirmed during scheme communication.

Conclusion

Vacuum casting plays a vital role in early-stage product verification, lowering injection molding trial costs, and supporting engineering decisions with fast, controllable quality. Xiamen Ruicheng ensures a standardized process covering material consistency, vacuum stability, and dimensional precision, providing a robust development path. When balancing speed and risk, a standardized vacuum casting process delivers valuable insights across the entire development phase. It is not just prototyping, but a comprehensive quality assurance system for the entire product development lifecycle.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!