Introduction

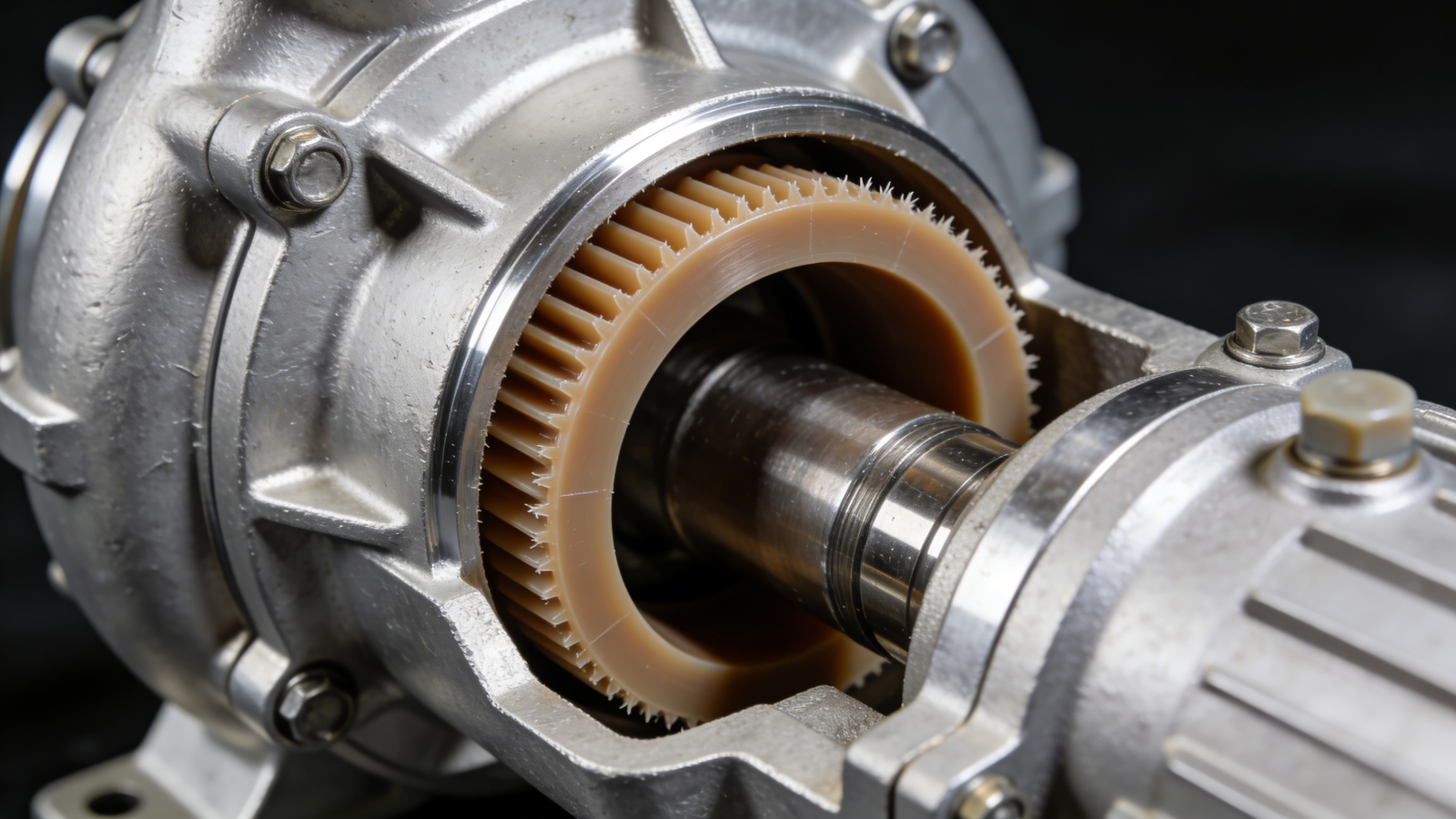

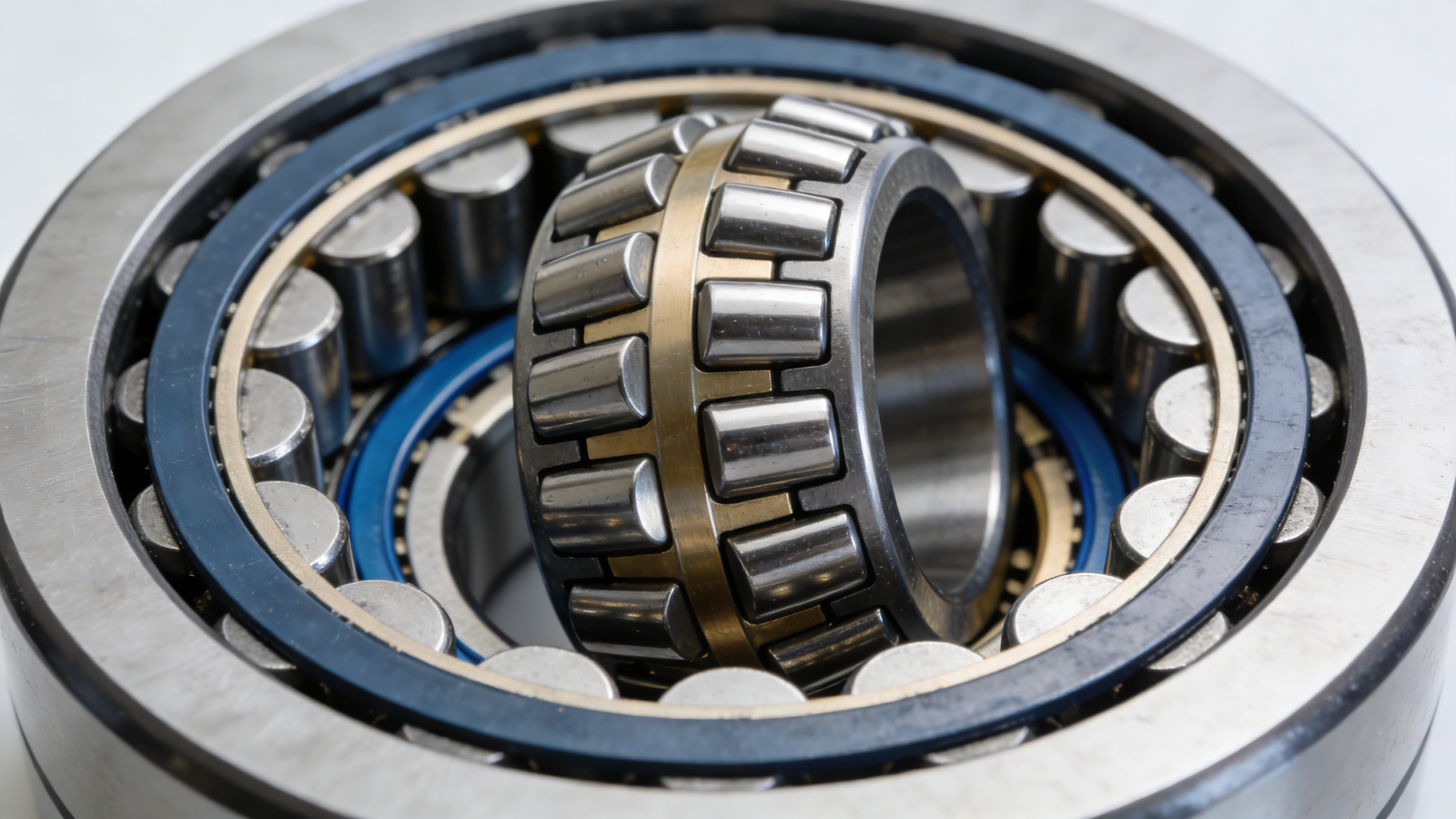

In the precise world of high-end bearings, the failure of any single component can lead to a complete shutdown of the entire transmission system. As the core of bearing cages, sealing rings, or sliding bushings, the performance of PEEK (Polyetheretherketone) wear-resistant injection molded parts directly determines the lifespan and reliability of bearings under extreme conditions such as high speed, high temperature, and heavy load. However, focusing solely on material grades is far from sufficient to address the challenges of complex real-world applications. Many procurement decisions fall into the trap of parameter comparison in the early stages, overlooking the systemic connection from material science to molding processes.

The real risks often hide beyond the data sheet—for instance, internal residual stress caused by inappropriate injection molding processes can lead to dimensional creep and premature cracking during long-term use. Xiamen Ruicheng believes that a successful procurement is a systems engineering task that shifts from "performance parameters" to "application-specific solutions." This means you need not just a parts supplier, but a partner capable of reverse-engineering design, manufacturing, and validation from the application end.

With Excellent Wear Resistance, Why Does Bearing Life Still Fall Short?

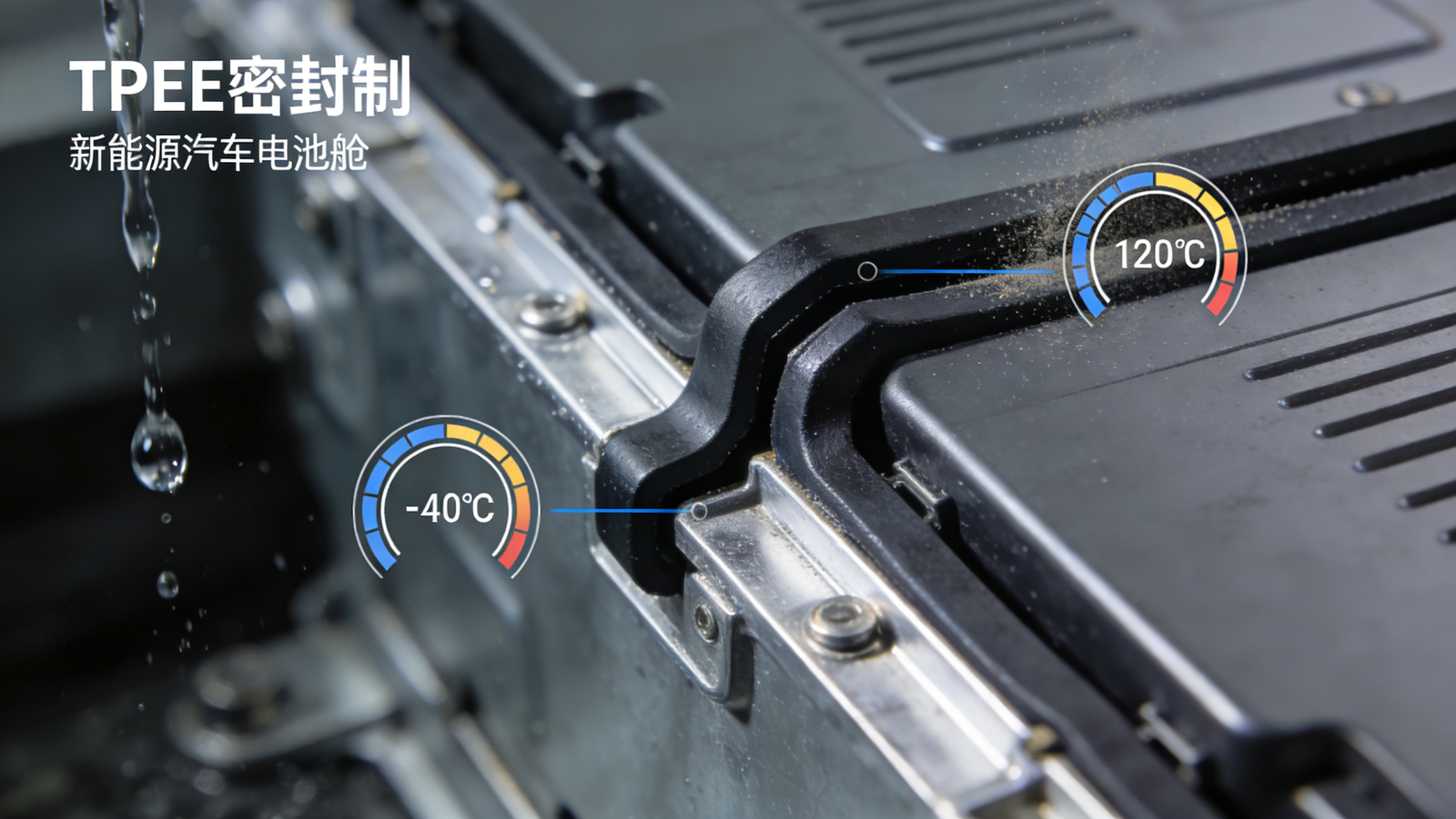

When you select a PEEK material with a high wear resistance grade for your bearing but find its actual service life falls far short of theoretical calculations, the problem often lies not in the material itself. A single wear factor (like the K-value) cannot fully reflect the part's true behavior under complex dynamic loading. Friction within a bearing is a complex, multi-factor coupling result, involving the counterface material, lubrication conditions, and most critically—the PV Limit (Pressure x Velocity). Under high-speed conditions, if the heat generated by friction cannot dissipate promptly, it can cause localized PEEK temperatures to exceed its glass transition temperature, leading to instant softening and Rapidly accelerated wear. Furthermore, internal stresses generated during the injection molding process can become potential crack initiation sites.Wear resistance is a system property that requires reverse definition and validation from the application side.

Matched Tribo-Pair Design: We assist in recommending surface treatments or modified PEEK compounds based on your bearing steel grade or ceramic type to form an optimal friction pair.

Dynamic PV Value Verification: We help analyze the instantaneous PV values during bearing start-stop, speed variation, and shock loads to ensure the selected PEEK grade operates within its safe window.

Thermal Management Consideration: Through simulation and structural design, we optimize the part's heat dissipation path to prevent performance degradation due to heat buildup.

Process-Induced Stress Mitigation: Employing scientific mold design and precise temperature control minimizes internal stress from the manufacturing source.

💡 Therefore, assessing wear resistance must go beyond the data sheet to involve systematic verification based on real operating conditions.

Parameters Are Met, But How Do You Verify a Supplier's True Molding Capability?

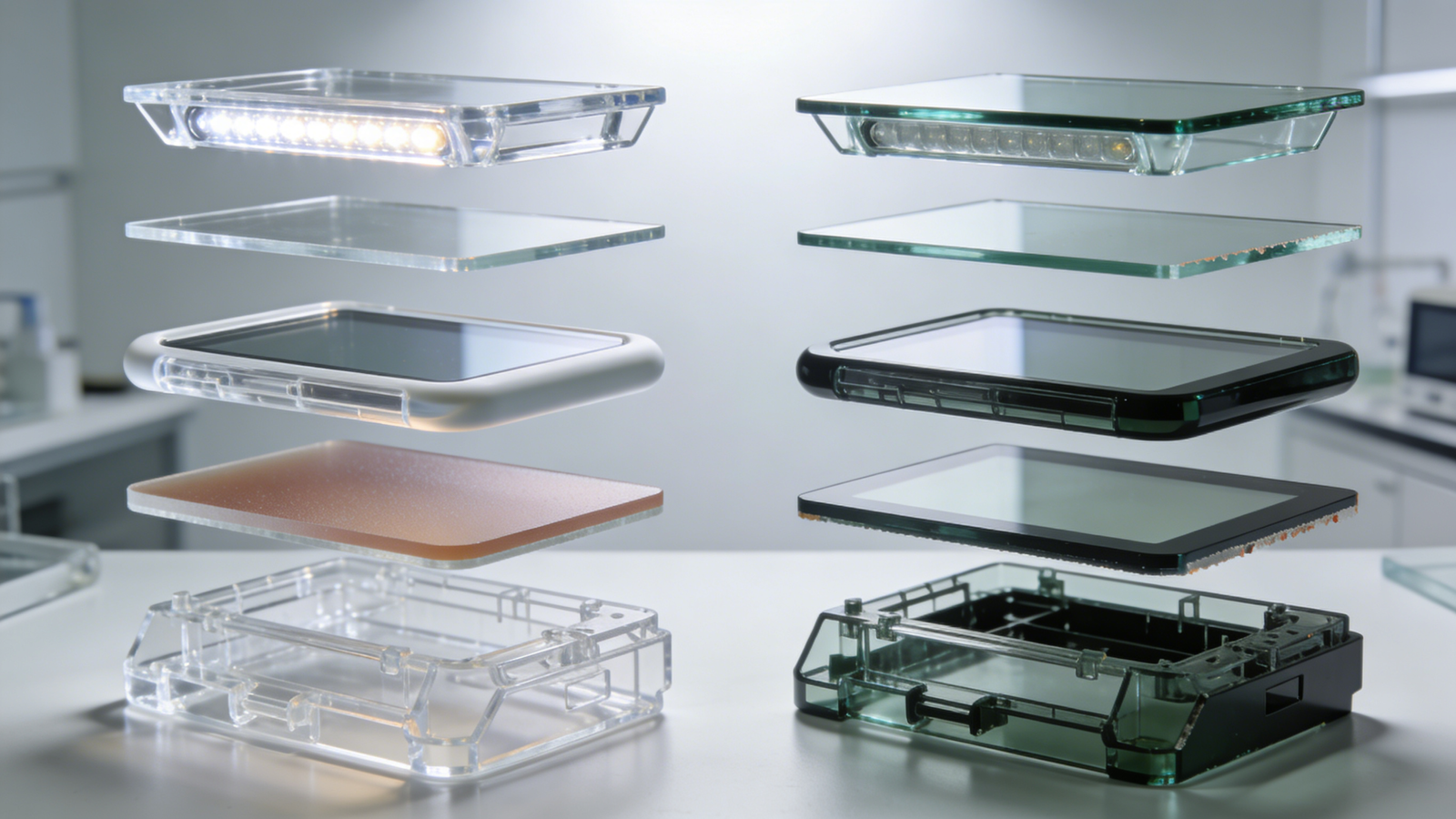

Material certification reports and physical property data provided by a supplier are merely entry tickets. For high-performance polymers like PEEK, 90% of their final performance is determined by the injection molding process. How can you be sure a supplier's process capability consistently translates the potential of premium pellets into the precision part in your hand? PEEK's high melting point, high viscosity, and hygroscopic nature impose stringent demands on every aspect of precision molding and the accuracy of the mold temperature control system.True capability is demonstrated through absolute control of the process, not just promises about the outcome.

Material Handling Process: We employ dedicated dehumidifying drying systems to ensure PEEK pellet moisture content is below 0.02% before molding.

High-Precision Molding Equipment: We use fully electric or hybrid machines with dedicated screws/barrels, ensuring homogeneous plasticization of PEEK melt.

Precision Mold Temperature Control: Oil temperature controllers with ±1°C accuracy enable zone-specific mold temperature control for consistent properties.

Full-Process Quality Control: From first-article inspection using CMMs to regular SPC on critical characteristics, ensuring batch-to-batch stability.

🔬 Verifying a supplier means verifying the scientific rigor and stability of their process control.

The Drawing Is Perfect, So Why Do Production Parts Have Assembly or Noise Issues?

Tolerance callouts on an engineering drawing are static, but PEEK parts within a bearing system operate under dynamic temperature changes and loads. The root cause of many assembly interferences lies in the design phase's failure to fully account for material property differences between PEEK and metal. PEEK's Coefficient of Thermal Expansion (CTE) is significantly higher than that of bearing steel, and its characteristic creep behavior can cause fit issues and noise after temperature rise or under sustained load.Successful design involves simulating and compensating for the material's behavior in the actual working environment beforehand.

Application-Based Tolerance Design: We help calculate the thermal expansion difference to adjust tolerance bands for a "precision fit at operating temperature."

Creep-Resistant Structural Optimization: We enhance long-term dimensional stability through strategic design or the use of reinforced PEEK grades.

Pre-Assembly and Testing: We provide prototype samples for pre-assembly and testing on your rigs, identifying issues early.

Material Modification Support: We offer customization options to optimize CTE or creep performance for extreme conditions.

📐 Incorporating material dynamics into front-end design is crucial, requiring reverse input from molding experts.

PEEK Material Comparison Matrix for High-End Bearing Applications

| Performance Dimension | Unfilled PEEK | 30% Glass-Filled | 30% Carbon-Filled | PTFE/Graphite Modified |

|---|---|---|---|---|

| Key Characteristics | High toughness, Chem resistance | High stiffness, Low warpage | Very high stiffness, Excellent wear | Very low friction, Self-lubrication |

| Typical Wear Resistance | Good | Very Good | Excellent | Best (for friction) |

| Continuous Service Temp. | ~250°C | ~250°C | ~250°C | ~250°C |

| Coeff. of Thermal Expansion | High | Lower | Very Low | Moderate |

| Creep Resistance | Fair | Good | Excellent | Good |

| Typical Bearing Application | Corrosive environment seals | General structural parts, Cages | High-speed/Heavy-load components | Dry/starved lubrication bushings |

Contact Us for a customized material selection analysis based on your exact operating conditions.

The Four Pillars of a Reliable Supply Partnership

Selecting a supplier for PEEK wear parts begins with technical dialogue on parameters, but it doesn't end there. Xiamen Ruicheng is convinced that lasting cooperation is built on four pillars: "Technical Collaboration, Manufacturing Reliability, Agile Response, and Shared Risk." This means we position ourselves as an extension of your R&D and supply chain, from collaborative simulation to traceability management and rapid response.

1.Depth of Technical Collaboration: Our application engineers provide support from material selection to process validation.

2.System of Manufacturing Reliability: Certified under IATF 16949 with digital MES for stable, controlled processes.

3.Network for Agile Response: Safety stock and flexible scheduling ensure seamless transition between prototyping and volume.

4.Commitment to Shared Risk: We provide complete test reports and warranties, with swift resolution for any attributable issues.

Frequently Asked Questions (FAQ)

Q1: What are the core advantages and key quality assurances for your PEEK parts?

A: Our core advantage is the integration of material application technology and precision molding. We use top-tier materials, possess specialized PEEK process packages for critical tolerance control, and conduct 100% inspection with optional third-party reports.

Q2: What information is needed for a quick quote and proposal?

A: Please provide part drawings, operating conditions (speed, load, temperature, lubrication), counterface material, and preliminary demand. We acknowledge within 2 hours and deliver a proposal in 1-3 business days with free samples.

Q3: What are the MOQ, lead time, and payment terms?

A: Trial MOQ: 50-100 pcs. Batch MOQ: 1000-5000 pcs. Lead times: prototypes 5-10 days, small batches 2-3 weeks, large batches 4-6 weeks. Rush orders: 7-10 days. Payment: T/T, negotiable for partners.

Q4: How do you handle dimensional deviations or underperformance?

A: Notify us within 7 business days. We initiate a root cause analysis and, if our responsibility, commit to corrective action within 48 hours. Core parts have a 12-month warranty.

Q5: Can you provide material customization for special conditions?

A: Yes. We modify PEEK compounds for specific needs (e.g., outgassing, chemical resistance). We also offer machining and surface treatments. Provide detailed parameters for a feasibility assessment and proposal within 5 business days.

Conclusion

Procuring PEEK wear-resistant injection parts has evolved into a strategic technical investment. The success of this investment depends on transforming isolated performance parameters into a full-spectrum technical dialogue spanning design, material, manufacturing, and validation. Xiamen Ruicheng looks forward to becoming your trusted partner on this value chain.

For expert assistance, visit our resource center or contact us.