Introduction

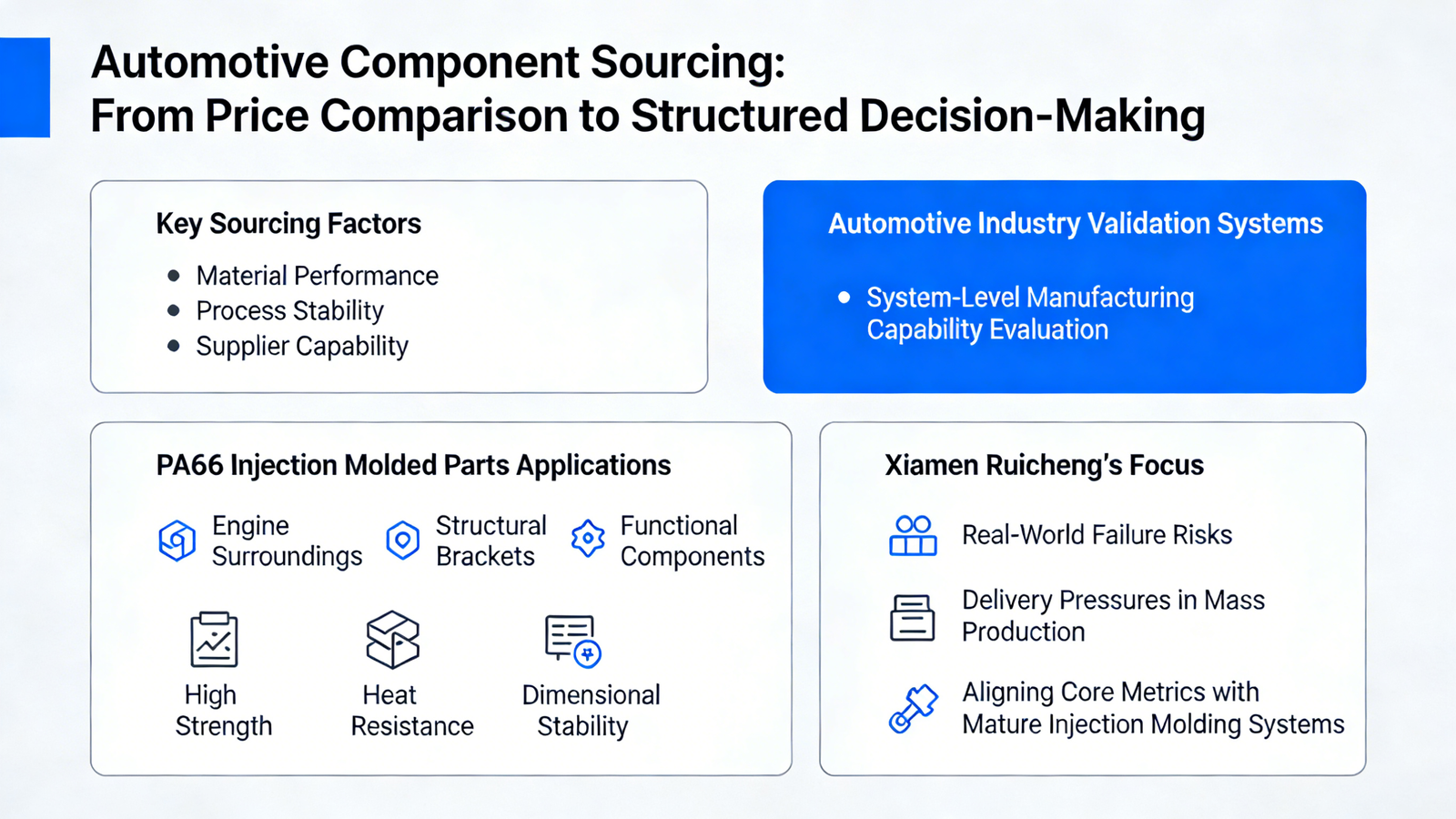

Automotive component sourcing is shifting from simple price comparison to a structured decision-making process, where material performance, process stability, and supplier capability jointly determine project success. PA66 injection molded parts are widely used in engine surroundings, structural brackets, and functional components due to their high strength, heat resistance, and dimensional stability.Under the automotive industry’s stringent validation systems, sourcing PA66 injection molded parts is no longer a material choice alone, but an evaluation of system-level manufacturing capability.

From Xiamen Ruicheng’s perspective, we focus more on real-world failure risks and delivery pressures that buyers may face during mass production. By identifying core metrics early and aligning them with mature injection molding systems, overall project uncertainty can be significantly reduced.

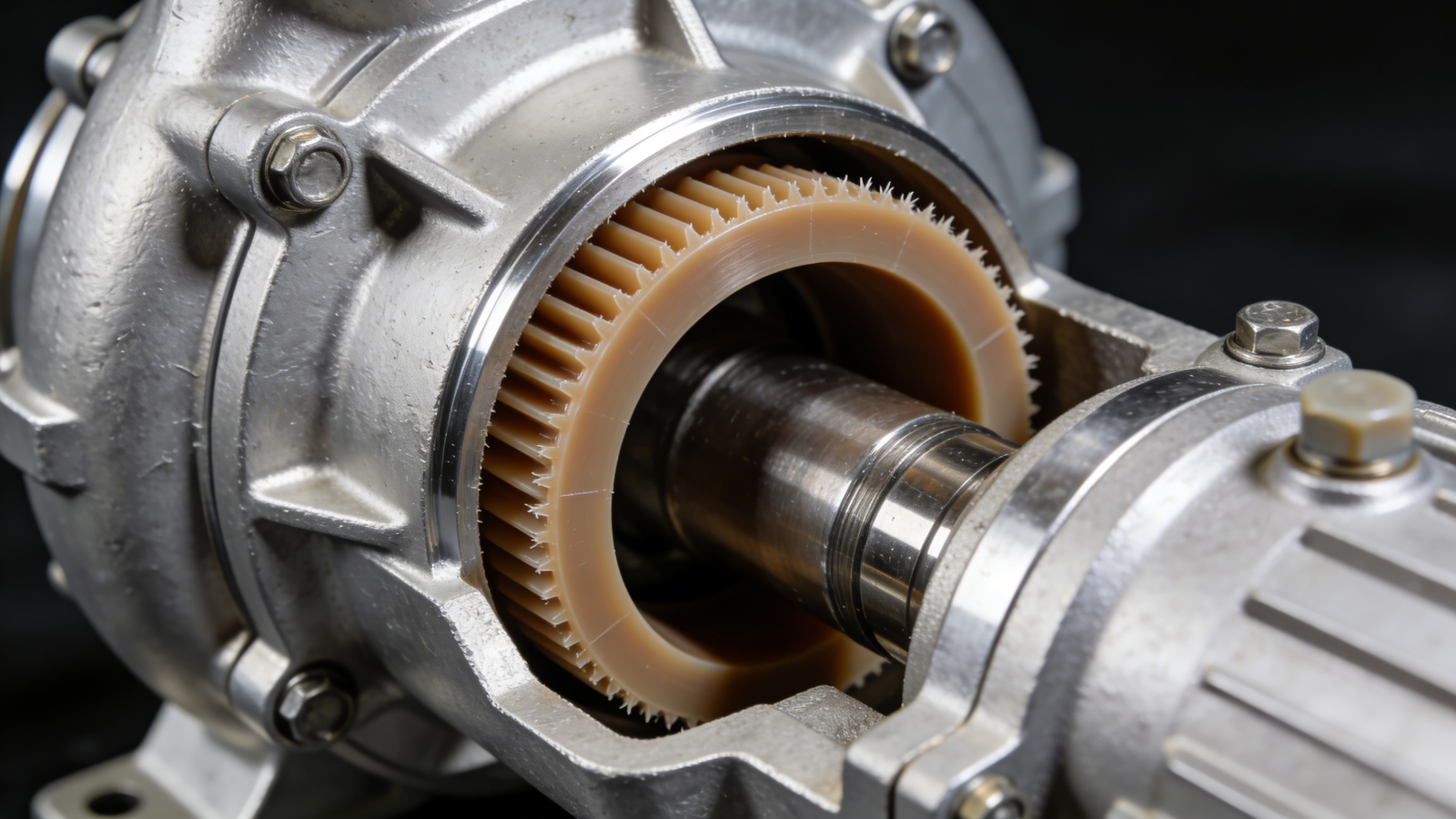

Does PA66 material performance truly match automotive operating conditions?

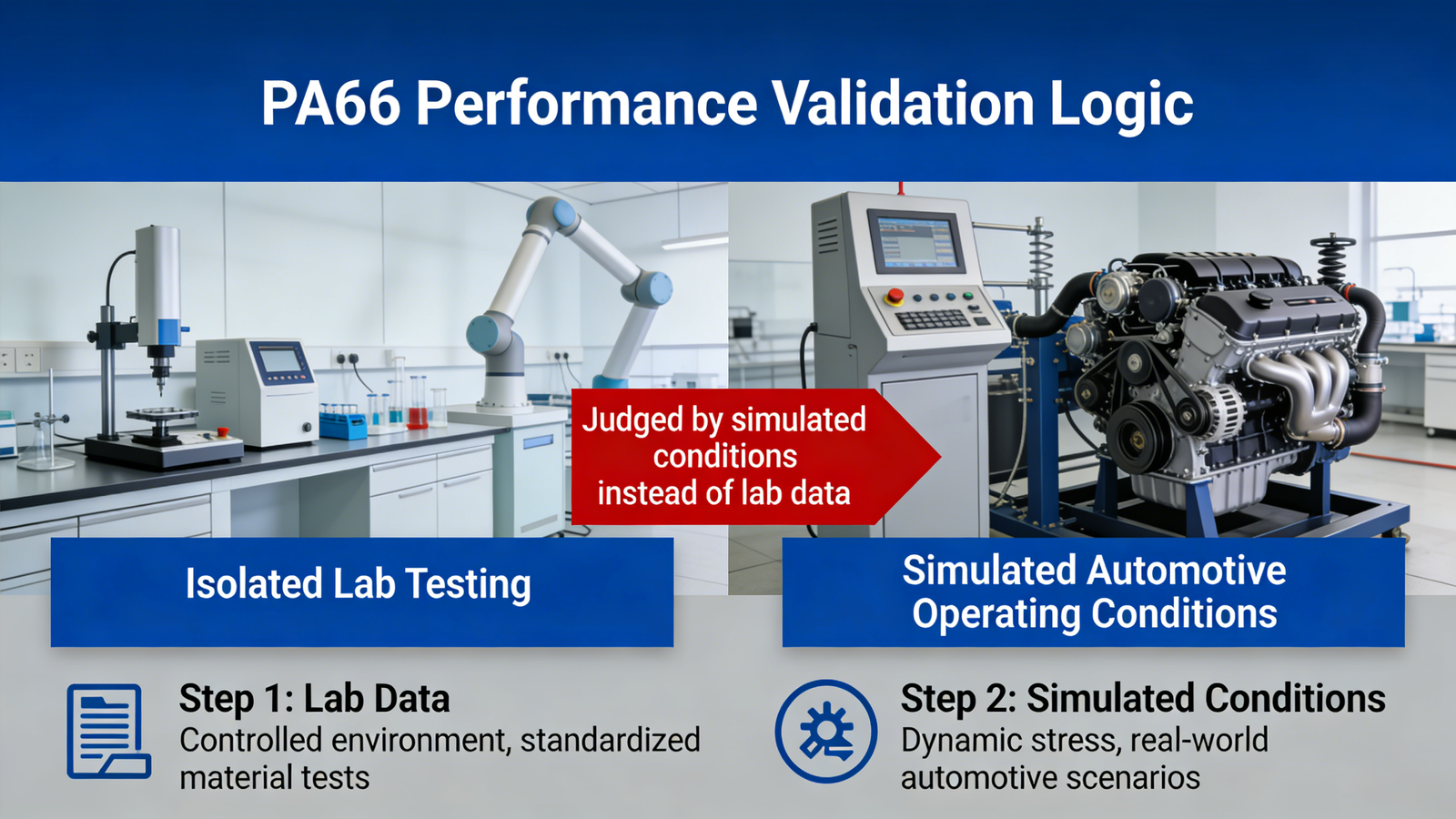

The performance of PA66 in automotive components depends not only on the resin grade itself, but also on its long-term stability under complex operating conditions, including thermal aging, mechanical retention, and fatigue resistance. Many sourcing risks stem not from insufficient datasheet values, but from a mismatch between the material system and real application conditions. At Xiamen Ruicheng, we evaluate projects based on both PA66 material properties and automotive application standards to prevent rework and recall risks caused by improper material selection.

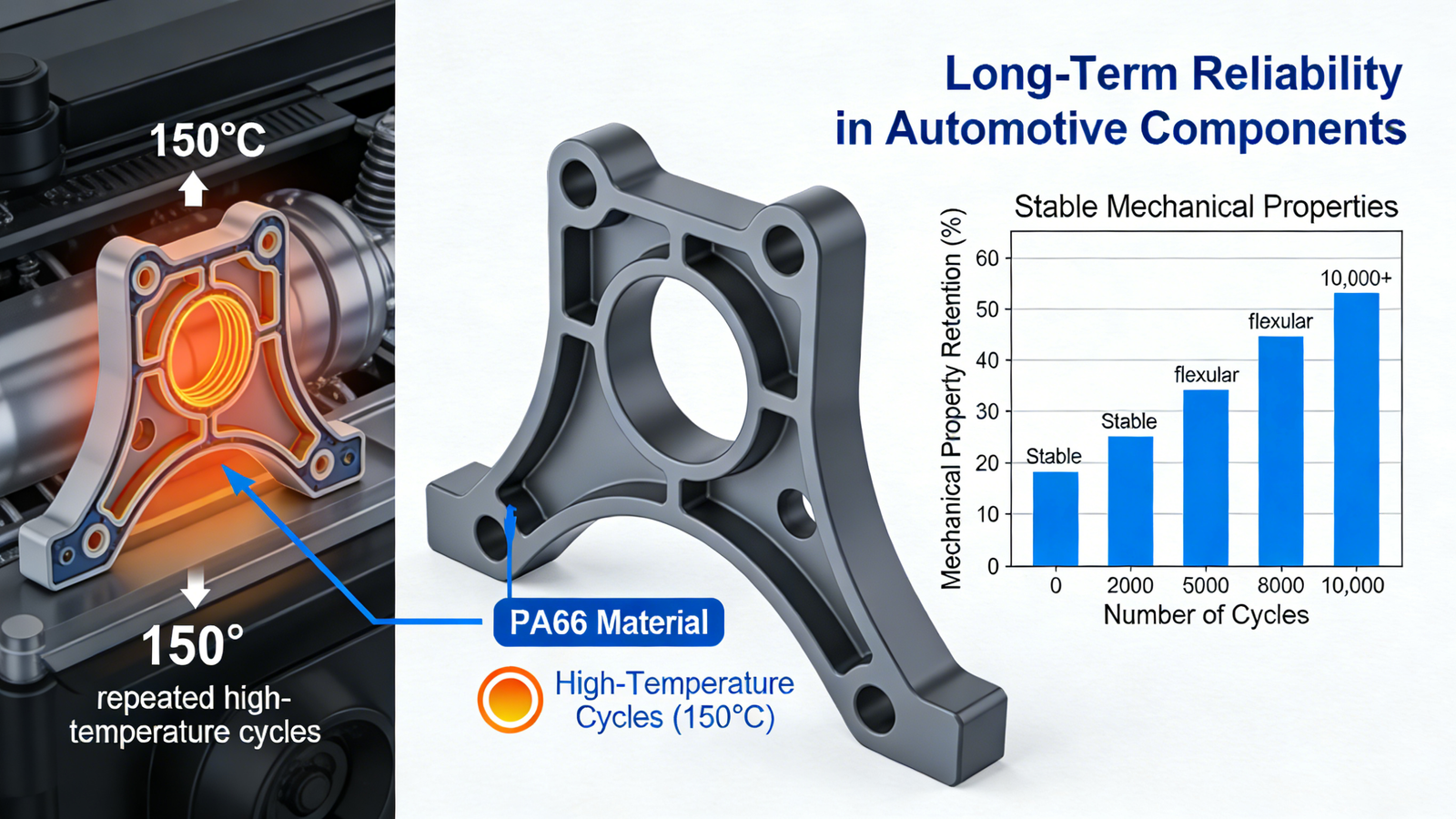

Thermal retention: Materials must maintain stable mechanical properties under repeated high-temperature cycles to ensure long-term reliability.

Mechanical strength: Actual molded strength depends on fiber content and orientation control rather than raw material data alone.

Environmental adaptability: Resistance to oil, humidity, vibration, and chemical exposure is essential in automotive environments.

Validation logic: Performance should be judged through simulated operating condition testing rather than isolated lab data.

🚗 Accurate material selection defines the real reliability boundaries of PA66 automotive injection molded parts.

How does injection process stability affect consistency of PA66 components?

In automotive mass production, consistency of PA66 injection molded parts is more critical than single-part performance, as minor variations can be amplified during assembly or durability testing. Process window control is the key differentiator between general molding and automotive-grade injection molding. Leveraging robust injection molding process control and extensive automotive manufacturing experience, Xiamen Ruicheng ensures high dimensional and performance consistency across production batches.

Processing window: Precise control of melt temperature, mold temperature, and packing pressure reduces internal stress.

Mold design: Proper runner and cooling system design directly impacts crystallinity and warpage risk.

Process monitoring: Real-time monitoring minimizes deviations caused by environmental or equipment fluctuations.

Batch consistency: Standardized operations enable smooth transition from pilot runs to mass production.

⚙️ Stable injection processes are the foundation for scalable application of PA66 automotive components.

Can the supplier’s quality system support the full automotive project lifecycle?

Automotive projects typically involve long cycles and high volumes, placing higher demands on supplier quality systems and responsiveness. Reliable PA66 injection molding supply is not just about delivering parts, but about delivering sustained quality commitment. Xiamen Ruicheng operates under the IATF 16949 framework and integrates comprehensive quality management systems to support customers from development through mass production.

System compliance: Quality systems must cover design, production, and change management.

Risk prevention: APQP and FMEA are used to identify potential failure modes in advance.

Rapid response: Clear timelines and accountability ensure efficient corrective actions.

Long-term collaboration: Support continuous improvement throughout the vehicle program lifecycle.

🛠️ Supplier system capability determines whether PA66 injection molded parts can be fully integrated into automotive supply chains.

Key Metrics Comparison for Automotive PA66 Injection Molded Parts

| Evaluation Dimension | General Supplier | Experience-Based Molder | Standardized Manufacturer | Xiamen Ruicheng |

|---|---|---|---|---|

| Material Understanding | Basic datasheet | Experience-driven | Standard selection | Application-level evaluation |

| Process Stability | High variation | Moderately controlled | Stable | High consistency |

| Quality System | Generic | Partial coverage | Complete | Automotive-grade |

| Project Support | Passive delivery | Cooperative | Proactive | Full lifecycle partnership |

Looking to determine which approach best fits your project? Reach out now via contact us

From sourcing decisions to mass production: PA66 injection molding support logic

Automotive component sourcing is a continuous process from requirement definition and sample validation to mass production delivery. In PA66 injection molding projects, Xiamen Ruicheng emphasizes early technical involvement and downstream delivery assurance. By bringing manufacturing expertise into the sourcing phase, buyers can significantly reduce trial-and-error costs and shorten project timelines.

1.Requirement analysis: Define critical metrics based on application and assembly conditions.

2.Solution co-development: Provide manufacturability-driven material and process recommendations.

3.Validation support: Assist with sample testing and data feedback.

4.Production assurance: Ensure long-term supply through stable capacity and quality systems.

Frequently Asked Questions (FAQ)

Question: What is the core quality baseline for your PA66 injection molded parts?

Answer: We benchmark against automotive-grade applications, defining critical mechanical and thermal metrics, verified through controlled processes and testing systems.

Question: What information is required to initiate a PA66 injection molding project?

Answer: Typically, drawings, application conditions, and estimated volumes are needed. Xiamen Ruicheng provides rapid evaluation and process-based quotations once received.

Question: How are lead times structured for different order volumes?

Answer: Pilot and mass production follow different scheduling strategies, with standard projects delivering initial batches within 7–10 working days and flexible support for urgent needs.

Question: How are quality issues handled after delivery?

Answer: We follow a defined corrective action process, providing rapid containment and resolution to minimize customer impact.

Question: Do you support customized PA66 injection molding solutions?

Answer: Yes, we offer application-specific material and process customization, with feasibility, timeline, and cost transparency provided upfront.

Conclusion

The core of sourcing PA66 injection molded parts for automotive components lies not in isolated parameters, but in overall system compatibility and long-term stability. By evaluating material performance, process control, and supplier quality systems holistically, buyers can effectively mitigate project risks. Choosing a manufacturing partner with proven automotive experience is critical to achieving stable mass production and continuous optimization. Xiamen Ruicheng remains committed to supporting customers from decision-making through delivery with professional injection molding expertise.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!