Polyoxymethylene (POM), commonly known as Delrin, is widely used in engineering fields for its excellent mechanical properties. However, its vibration damping performance in dynamic environments is a significant concern. This article will explore the vibration damping characteristics of Delrin from a professional perspective, analyze its performance under different operating conditions, and provide a reference for material selection.

The preceding text briefly described the importance of Delrin and the significance of research on its vibration damping performance. Understanding the viscoelasticity of Delrin is key to understanding its vibration damping mechanism. Next, we will analyze its dynamic mechanical properties and compare them with other materials to evaluate its potential in vibration damping applications.

How does the viscoelasticity of Delrin affect vibration damping?

As a polymeric material, Delrin exhibits significant viscoelastic characteristics due to its internal structure. This unique property enables Delrin to dissipate a portion of the mechanical energy into heat through the movement and friction of internal molecular chains when subjected to mechanical vibrations, thereby achieving vibration damping.

- Viscoelastic Nature: Delrin possesses both viscosity and elasticity, which is the foundation of its vibration damping performance.

- Energy Dissipation Mechanism: During vibration, internal friction within Delrin converts mechanical energy into heat for dissipation, achieving vibration damping.

- Deformation Hysteresis Phenomenon: Stress lagging behind strain leads to energy loss, and the area of the hysteresis loop reflects the vibration damping capacity.

- Temperature and Frequency Dependence: The vibration damping performance of Delrin is significantly affected by temperature and vibration frequency.

Changes in mechanical properties of Delrin?

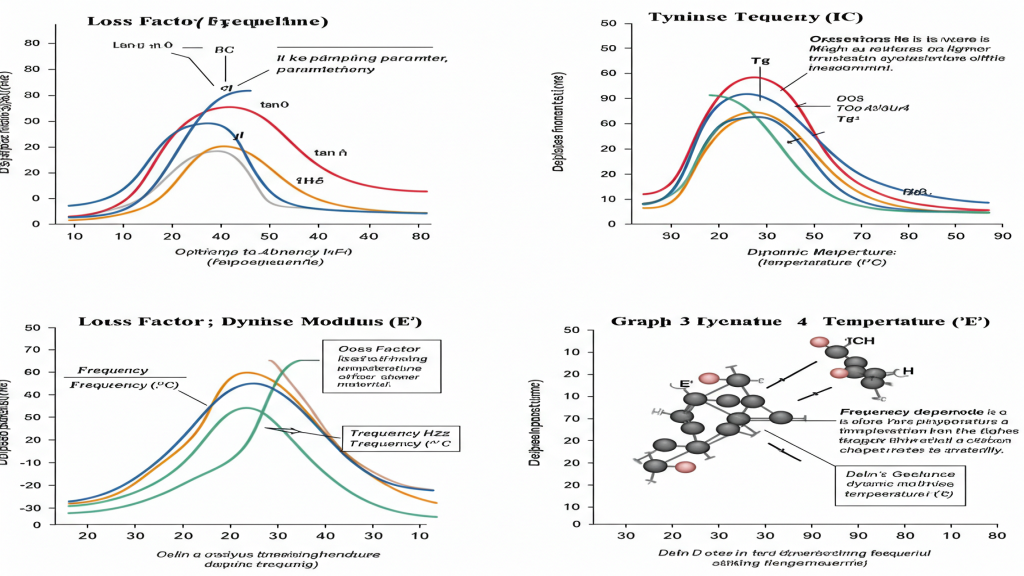

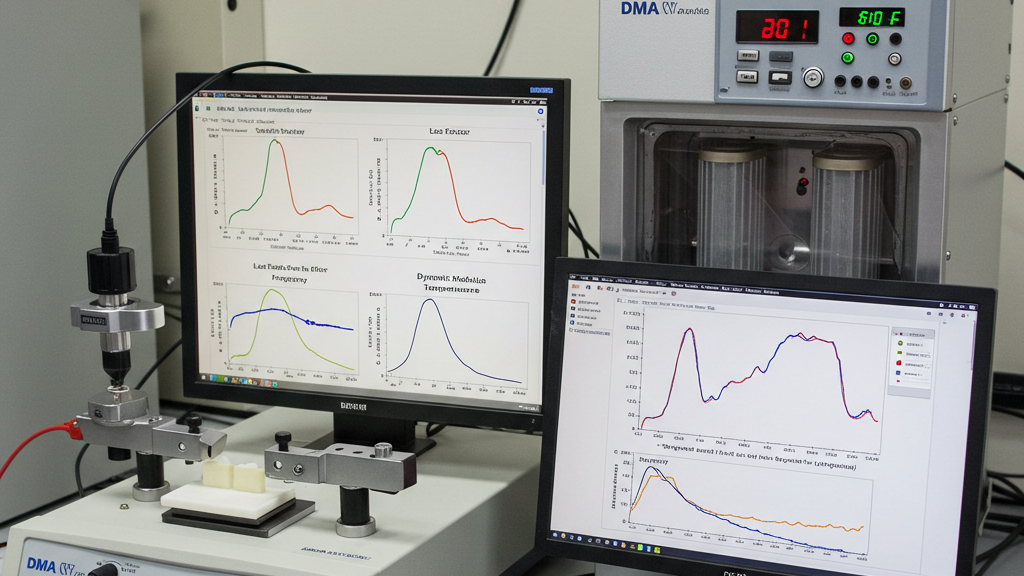

The dynamic mechanical properties of Delrin, especially the loss factor and dynamic modulus, are key indicators for evaluating its vibration damping effect in different application scenarios. These parameters are not fixed but exhibit complex response behaviors with changes in external environmental conditions (such as vibration frequency and operating temperature). Understanding these dynamic characteristics is crucial for engineers to select appropriate Delrin materials when designing components that need to withstand vibrations.

- Loss Factor vs. Frequency: The loss factor of Delrin may exhibit a peak with increasing frequency, corresponding to the optimal vibration damping frequency.

- Loss Factor vs. Temperature: Increasing the temperature increases the loss factor of Delrin, reaching a peak near the glass transition temperature.

- Dynamic Modulus vs. Frequency: The dynamic modulus of Delrin typically increases with increasing frequency, especially in the transition region.

- Dynamic Modulus vs. Temperature: Increasing the temperature usually decreases the dynamic modulus of Delrin, with a significant drop near the glass transition temperature.

How is the vibration damping performance of Delrin?

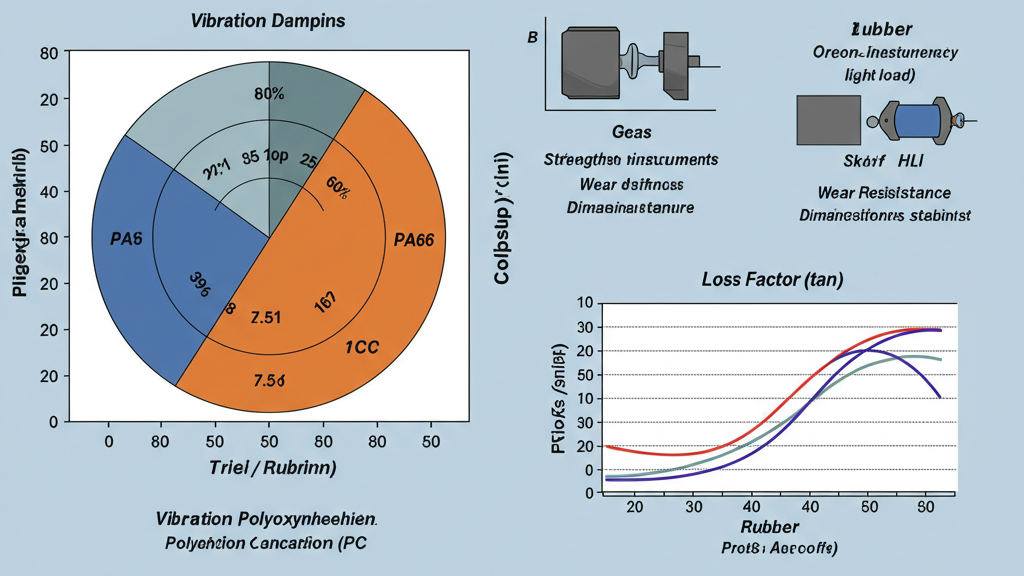

In engineering applications, material selection often requires trade-offs between various properties. Comparing the vibration damping performance of Delrin within a broader material system helps us clearly understand its positioning. By comparing Delrin with other common engineering plastics and vibration damping materials, we can more accurately assess its suitability in specific vibration environments and understand its inherent advantages and disadvantages.

- Positioning of Vibration Damping Performance: Delrin is not the best in vibration damping, but its high mechanical properties make it a compromise solution for applications requiring strength and some vibration damping.

- Comparison with Common Engineering Plastics: Compared to some tough plastics, Delrin's vibration damping may be slightly inferior, but it is superior in dimensional stability and wear resistance.

- Vibration Damping Advantages of Delrin: Delrin has a certain vibration damping capability under medium-to-high frequency vibrations, and its high rigidity helps reduce resonance, making it suitable for light-load vibration damping.

- Vibration Damping Disadvantages of Delrin: Delrin is limited in efficiently absorbing low-frequency, large-amplitude vibrations, making it inferior to professional vibration damping materials.

Performance comparison between Delrin and other plastics

| Material Name | Key Characteristics | Loss Factor (tan δ) Range | Dynamic Modulus (MPa) Range | Relative Damping Performance | Example Applications |

|---|---|---|---|---|---|

| Delrin (POM) | High Strength, High Rigidity, Wear-Resistant, Low Friction | 0.02 - 0.10 | 2500 - 3500 | Medium-Low | Precision Parts, Gears, Light Vibration Environments |

| Nylon (PA) | Good Toughness, Wear-Resistant, Self-Lubricating | 0.03 - 0.15 | 500 - 3000 | Medium | Gears, Bearings, Structures with Some Shock/Vibration Absorption |

| Polyurethane Elastomer (TPU) | High Elasticity, High Strength, Wear-Resistant, Excellent Damping | 0.10 - 0.50+ | 10 - 500+ | High | Buffer Pads, Vibration Dampers, High Damping Applications |

| Butyl Rubber (IIR) | Good Air Tightness, Good Chemical Resistance, Excellent Damping | 0.05 - 0.30+ | 1 - 100+ | High | Automotive Engine Mounts, Vibration Isolation Pads, Applications Requiring Good Damping |

Factors Affecting the Vibration Damping Effect of Delrin

The vibration damping performance of Delrin is not its inherent advantage, but it can be optimized through various means to meet specific application requirements. Modification is an effective way to improve the vibration damping effect of Delrin. In practical applications, engineers need to comprehensively consider operating conditions, performance requirements, and cost factors, and choose the appropriate optimization strategy to fully utilize the potential of Delrin in specific vibration environments.

1.Material Modification: Modifying Delrin by adding high damping components can effectively enhance its vibration damping performance.

2.Type and Content of Fillers: Selecting appropriate fillers and dosages can regulate the vibration damping effect of Delrin.

3.Structural Design: Clever structural design can significantly enhance the overall vibration damping capability of Delrin components.

4.Operating Temperature and Vibration Frequency: The actual operating temperature and frequency affect the vibration damping performance of Delrin and need to be considered.

Conclusion

As a high-performance engineering plastic, although the inherent vibration damping performance of Delrin is not outstanding, its vibration damping effect can be significantly improved through material modification (such as adding elastomers or viscoelastic resins), selecting appropriate filler types and contents, and employing clever structural designs (such as composite lamination or special geometric shapes).

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!