Introduction

HDPE industrial sensor housings offer strong impact resistance, chemical durability, and outdoor stability, making them one of the most popular choices in industrial product development. They maintain reliability in harsh environments while supporting high production efficiency, helping companies better manage manufacturing costs. As industries prioritize supply-chain stability, the overall value of HDPE housings becomes increasingly important.

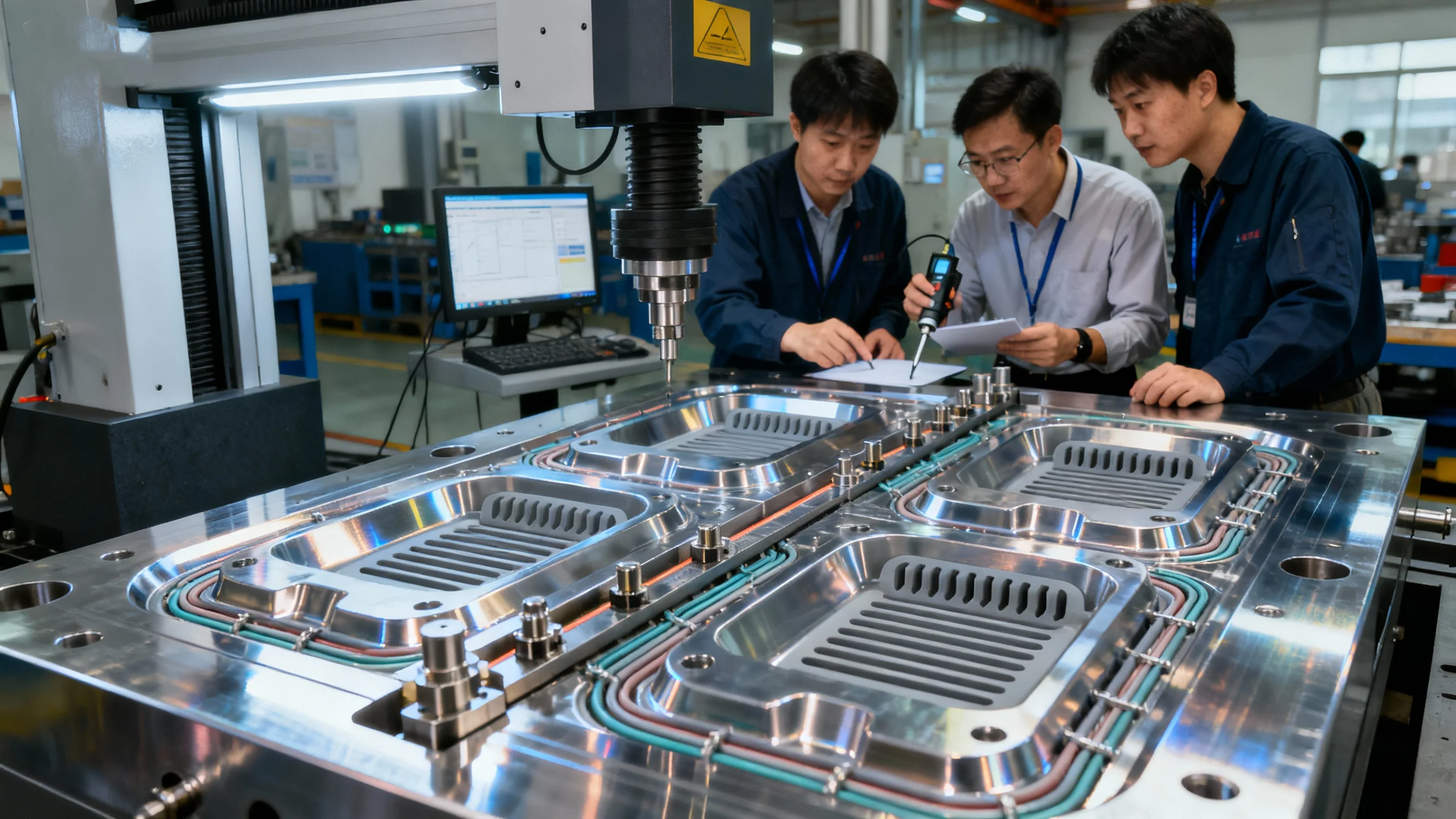

Xiamen Ruicheng has extensive experience producing industrial housings, utilizing optimized materials, mold design, and mass-production systems to reduce unit cost for clients. Stable processes and precision equipment ensure dimensional consistency, while customized reinforcement or cost-down solutions are available based on application needs. When a project transitions from R&D to mass production, a solid cost framework becomes the true foundation of competitiveness.

What factors determine the price of HDPE industrial sensor housings?

The pricing of HDPE housings depends on material selection, structural complexity, mold requirements, and production cycle efficiency, with batch size creating additional cost differences. In most cases, mold complexity and precision represent the highest initial cost, while production cycle time influences long-term unit pricing. Xiamen Ruicheng optimizes structure and process flow to maintain stable pricing. In mass production, design rationality often influences cost more than the material itself.

- Material Grade Selection: Different HDPE grades lead to varied material cost.

- Structural Complexity: More ribs, snaps, or waterproofing features increase mold investment.

- Mold Manufacturing Cost: Determines upfront investment and molding stability.

- Batch Size & Cycle Time: Affects unit cost and overall delivery efficiency.

😊 Multiple factors jointly determine the final cost of an HDPE housing.

How can you evaluate whether the mold cost for HDPE housings is reasonable?

Mold pricing is influenced by cavity count, parting design, venting quality, and expected mold life, along with differences in steel grade and machining requirements. Due to HDPE’s higher shrinkage, mold design accuracy is crucial to ensure stable production, making reasonable mold pricing a balance of durability and precision. Xiamen Ruicheng provides DFM optimization during the mold stage to avoid unnecessary spending. The true measure of mold cost is whether it supports reliable long-term production.

- Steel Grade Comparison: Higher-grade steels offer longer mold life.

- Parting & Split Design: Avoids excessive segmentation and unnecessary cost.

- Cavity Planning: Directly impacts output and unit cost.

- Cooling Layout Quality: Influences cycle time and product consistency.

🔍 A reasonable mold quote reflects the balance of lifespan, precision, and output.

How can the unit cost of HDPE housings be controlled during mass production?

Unit pricing in mass production is shaped by material use, cycle efficiency, labor allocation, and quality consistency, making process optimization the key to cost reduction. Proper wall-thickness design, rib layout, and gate configuration can significantly enhance production efficiency for HDPE housings. Xiamen Ruicheng ensures stable quality through controlled automation and process monitoring. Stable mass-production capability directly determines the final unit price.

- Cycle Optimization: Boosts efficiency and reduces cost.

- Material Utilization: Proper gate/runner layout minimizes waste.

- Automated Part Handling: Reduces labor requirements.

- Defect-Rate Control: Ensures stable cost by improving yield.

📦 Cost control in mass production depends on planning and process efficiency.

Cost Drivers for HDPE Sensor Housing Pricing

| Category | Material Grade | Structural Complexity | Mold Investment | Production Cycle |

|---|---|---|---|---|

| Cost Impact | Medium | High | High | Medium-High |

| Typical Variation | ±10% | ±30% | Largest initial cost | Key driver of unit price |

| Control Method | Choose proper HDPE grade | Optimize structure | Configure mold properly | Improve automation |

| Applicable Stage | All stages | Design phase | Early investment | Mass production |

Choosing the correct cost structure is the first step to achieving predictable pricing—[contact us](https://www.plasticxperts.com/contact) for a tailored evaluation for your project.

Expansion

HDPE sensor housings deliver strong environmental resistance, impact durability, and low moisture absorption, making them suitable for industrial, outdoor, and energy-sector applications. Xiamen Ruicheng provides fully customized production flexibility, including material formulation, mold design, and structural optimization. For demanding applications, reinforced structures and upgraded materials can significantly extend the housing’s service life.To ensure reasonable unit pricing, optimizing wall-thickness transitions, enhancing mold cooling performance, and designing efficient gate locations are effective strategies. Early-stage prototyping can also reduce risk and help achieve a stable mass-production plan.

1.Material Upgrades: Improve long-term durability.

2.Structural Optimization: Remove unnecessary cost.

3.Process Enhancement: Strengthen mass-production capability.

4.Pilot Validation: Reduce risk before scaling.

FAQ (HDPE Industrial Sensor Housing)

Q1: What are the core quality standards for HDPE industrial sensor housings?

Dimensional tolerance within ±0.1mm, stable molding processes, and full material traceability to ensure durability and environmental resistance.

Q2: How do I contact suppliers and obtain a quotation for HDPE sensor housings?

Send your CAD/STEP drawings; Xiamen Ruicheng provides DFM review and quotation within 12 hours, with sample-making support available.

Q3: What are the MOQ and delivery cycle for HDPE industrial sensor housings?

MOQ starts at 100 pcs; prototyping takes 3–5 days, mass production 7–15 days, and urgent orders can be expedited.

Conclusion

The reasonable pricing of HDPE industrial sensor housings depends on balancing materials, mold cost, and mass-production efficiency, while differences in process capability

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!