Lightweighting has become a key trend in industrial upgrading, and polypropylene (PP) sheets are emerging due to their low density and excellent performance. This article focuses on their potential in lightweight design, providing a professional analysis from the perspectives of material properties, technical advantages, and application prospects. It aims to provide guiding references for related industries.

The low density of polypropylene sheets is an inherent advantage for lightweighting. However, to fully realize its potential, it also relies on advanced modification technologies and innovative processes. In the next stage, we will explore how to improve the comprehensive performance of polypropylene sheets through technical means, so that they can meet the requirements of strength and durability while being lightweight, thereby expanding application areas.

What are the potentials of polypropylene sheet in lightweight design?

Polypropylene sheets, with their significant low-density characteristics, exhibit an inherent advantage in the trend of seeking product lightweighting. Compared to commonly used metals and some engineering plastics, the lightweight nature of polypropylene can directly reduce the overall weight of products, providing downstream industries with solutions in terms of energy conservation, emission reduction, and improved product performance.

- Significant Low Density: The low density of polypropylene sheets makes their weight far lighter than traditional materials at the same volume, laying the foundation for lightweighting.

- Higher Potential for Specific Strength and Specific Stiffness: Through modification and design optimization, polypropylene sheets can achieve excellent specific strength and specific stiffness, meeting performance requirements under lightweighting.

- Reduced Transportation and Installation Costs: Lightweight polypropylene sheets can effectively reduce the transportation and installation costs of products.

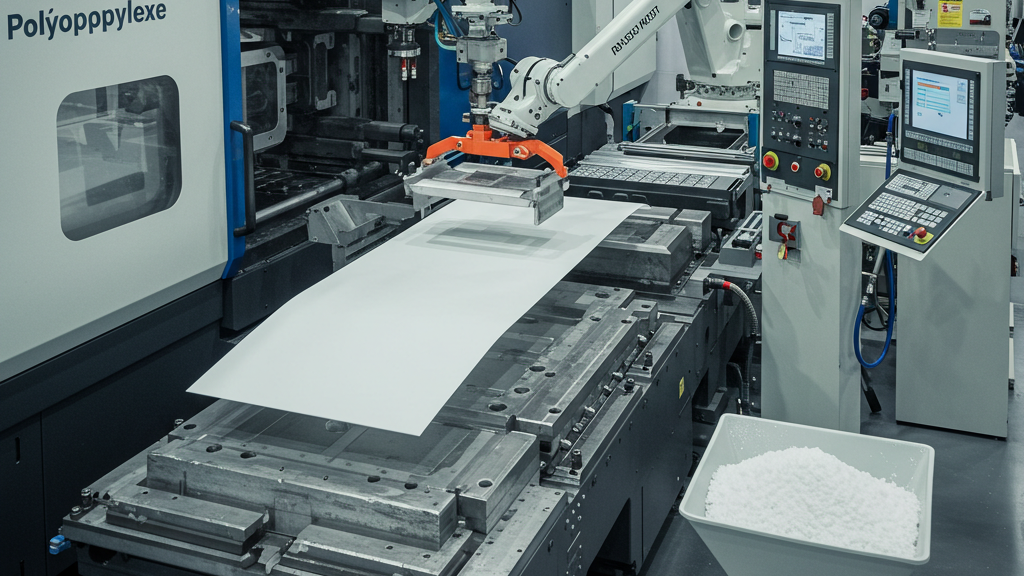

- Design Flexibility and Integrated Molding: Polypropylene sheets are easy to process into complex structures and achieve integrated molding, further optimizing lightweight design.

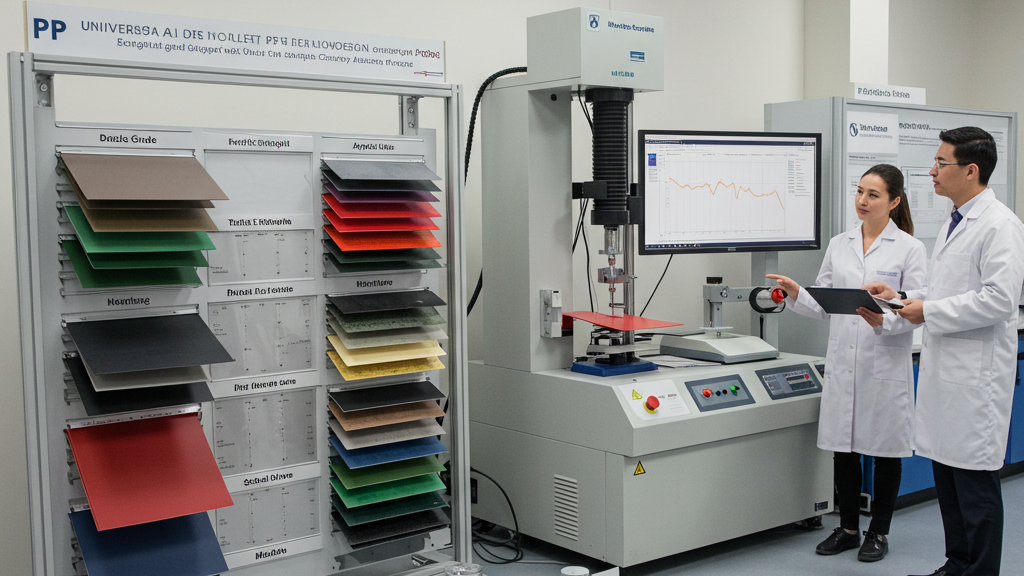

What technologies strengthen polypropylene sheets to adapt to lightweight?

Relying solely on the inherent lightweight characteristics of polypropylene sheets is not sufficient to fully meet the lightweighting design needs under complex working conditions. By introducing advanced modification technologies and precise processing techniques, the strength, rigidity, and other key properties of polypropylene sheets can be significantly improved, enabling them to achieve efficient lightweighting in a wider range of applications.

- Glass Fiber or Carbon Fiber Reinforced Modification: Adding high-strength fibers can significantly improve the strength and rigidity of polypropylene sheets, achieving high performance under lightweighting.

- Mineral-Filled Modification: By adding mineral fillers, the rigidity and dimensional stability of polypropylene sheets can be improved while controlling costs.

- Polymer Blending Modification: Blending with other high-performance polymers can customize and improve the comprehensive performance of polypropylene sheets to suit lightweighting needs.

- Structural Foaming or Microcellular Foaming Technology: Introducing air bubbles reduces the density of polypropylene sheets, achieving better lightweighting effects while ensuring performance.

In Which Lightweight Designs Have Polypropylene Sheets Been Applied?

With its increasingly optimized performance and inherent lightweighting advantages, polypropylene sheets have demonstrated significant application potential and successful practical cases in various industries and product designs. From the automotive industry to consumer electronics and logistics packaging, polypropylene sheets are injecting new vitality into the performance improvement and cost optimization of related products through their lightweight characteristics.

- Automotive Industry: Polypropylene sheets are used in automotive interior and exterior trims and structural components, helping to reduce the weight of the entire vehicle and improve energy efficiency.

- Logistics Packaging: Lightweight and durable polypropylene sheets are used to manufacture packaging materials, reducing transportation costs and protecting products.

- Consumer Electronics: Lightweight and high-strength polypropylene composites are used in electronic products, achieving thinner, lighter, and more portable designs.

- Construction Sector: Polypropylene sheets are used in non-load-bearing structures and decorations, reducing the load on buildings and facilitating construction.

Application and benefit analysis of polypropylene sheet

| Potential Dimension | Specific Manifestation | Value for Lightweight Design | Future Development Trends and Prospects |

|---|---|---|---|

| Density Advantage | Density significantly lower than metals and some engineering plastics (0.90-0.92 g/cm³) | Reduces product weight from the source, providing a foundation for lightweighting | Developing new PP materials with even lower density |

| Performance Enhancement Technologies | Glass/Carbon Fiber Reinforcement, Mineral Filling, Polymer Blending, Foaming Technology | Meets or enhances key performance indicators like strength, stiffness, and durability while lightweighting | Researching higher-performance modified PP materials, optimizing composite processes |

| Application Field Expansion | Lightweight applications in automotive, logistics packaging, consumer electronics, construction, etc. | Replaces heavier traditional materials, achieving product upgrades and cost optimization | Exploring applications in aerospace, medical devices, and other fields with higher lightweighting demands |

| Design and Process Optimization | Structural optimization design, integrated molding, etc. | Reduces the number of parts, simplifies assembly, further reduces weight | Combining with advanced manufacturing technologies (e.g., 3D printing) to achieve more complex lightweight structures |

New Potential of Polypropylene Sheets in Lightweighting

With the continuous breakthroughs in technology and the increasingly refined demands for lightweighting across various industries, polypropylene sheets, with their constantly improving performance and flexible plasticity, will open up innovative application spaces in broader fields. Polypropylene sheets will play an increasingly important role in the future wave of lightweighting design, becoming an important force driving industrial innovation and sustainable development.

1.Aerospace Sector: High-performance polypropylene composites are expected to be used in aerospace non-load-bearing and secondary load-bearing structures, achieving lightweighting and cost-effectiveness.

2.Medical Device Sector: Lightweight and corrosion-resistant modified polypropylene sheets can be used to manufacture lightweight medical equipment and components, improving ease of operation and patient comfort.

3.Wearable Devices and Smart Homes: Lightweight and moldable polypropylene sheets can be applied to equipment housings and structural components through precision molding, achieving a lightweight design.

4.New Energy and Energy Storage Sector: High-strength and flame-retardant polypropylene composites are expected to be used in battery packs and energy storage equipment housings, achieving

Conclusion

Thanks to its inherent low-density advantage, polypropylene sheets will usher in broader development space in terms of material innovation, process optimization, and cross-field applications. It will continue to empower the lightweighting upgrade of various industries and create new commercial value.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!