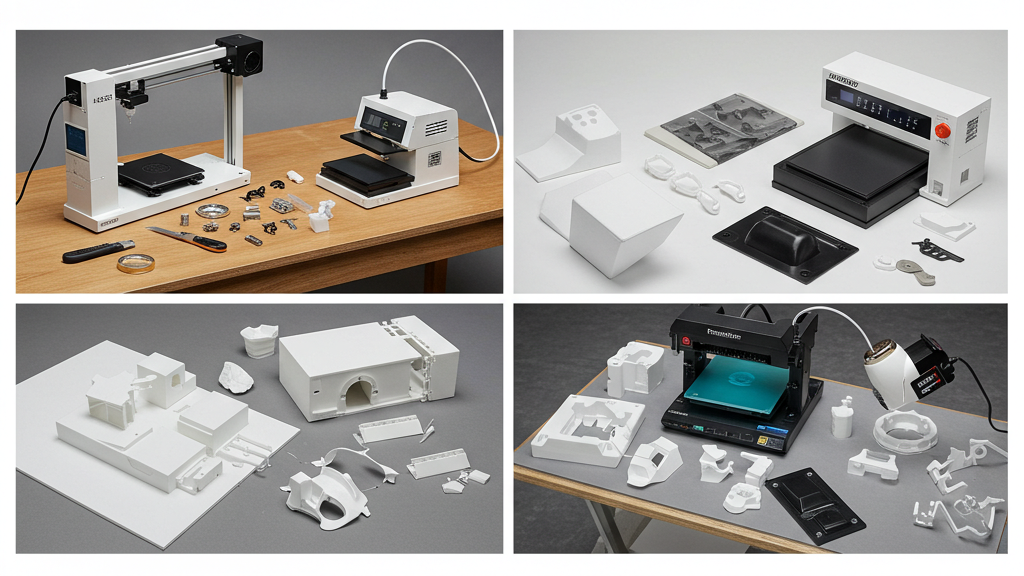

Material selection is crucial for model making, and ABS plastic stands out due to its unique properties. This material is easy to mold and possesses both toughness and impact resistance, providing modelers with a wide creative space.

Therefore, ABS plastic sheets have prominent advantages in model forming and post-processing. Whether it's detailing or building complex structures, they can provide strong support. The final presentation effect of the model is also critical.

In which model-making stages is ABS mainly used?

In the model-making process, the selection of materials is often closely linked to specific production stages. So, in which key steps of model making does ABS plastic sheet, known for its versatility, play an important role? Let's focus on exploring.

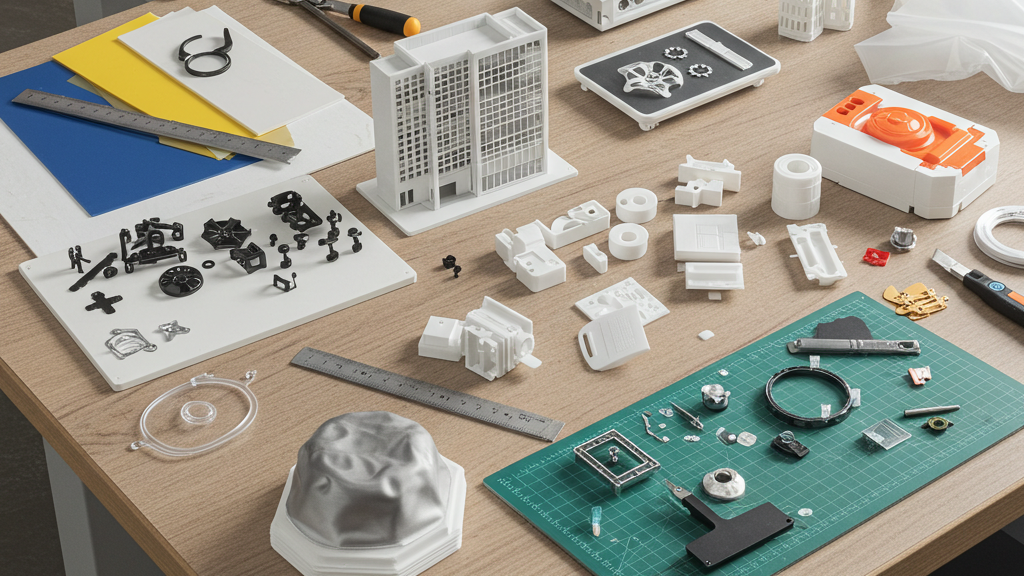

- Main Structure Construction: ABS sheets have moderate strength, are easy to cut and bond, and are often used for building the framework, outer shell, and internal support structures of models, providing a solid foundation.

- Detail Part Production: Through laser cutting, CNC machining, or manual shaping, ABS can be used to precisely produce various small parts of models, such as decorations, connectors, functional components, etc.

- Surface Shaping and Covering: ABS sheets can be secondarily formed by processes such as heat bending and vacuum forming to create curved surfaces, shells, or coverings on the surface of the model, achieving complex appearance designs.

- Prototype and Mold Making: Due to its good dimensional stability and machinability, ABS is also often used to make prototypes of product designs, and even as a material for simple molds, providing possibilities for small-batch replication.

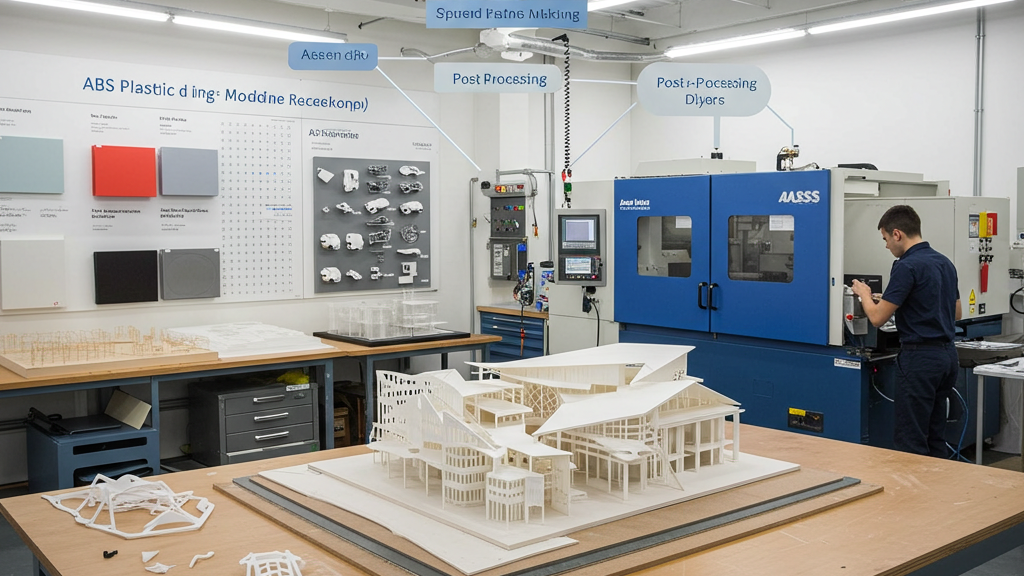

What are the characteristics of ABS processing performance?

ABS plastic has a wide range of applications in the field of model making, largely due to its commendable processing performance. Compared to other common model materials, ABS is less prone to chipping during cutting, has good thermoplasticity during shaping, and can be securely connected in a variety of ways.

- Easy to Cut and Engrave: ABS has a moderate hardness, allowing for precise cutting and engraving using laser cutting machines, CNC engraving machines, or even hand tools. The edges are relatively smooth and not prone to chipping.

- Good Thermoplasticity: ABS softens when heated, allowing for various thermoforming processes such as heat bending, vacuum forming, and injection molding to create complex curved surfaces and three-dimensional shapes.

- Multiple Connection Methods: ABS can be securely bonded with a variety of adhesives, or it can be connected by hot melting, screw fixing, and other methods, which is convenient for model assembly and structural reinforcement.

- Good Surface Treatment Adaptability: The surface of ABS is smooth, making it easy to sand, paint, screen print, and perform other surface treatments to achieve rich colors and textures, enhancing the aesthetics of the model.

What is the durability and maintainability of ABS models?

The value of a model is not only reflected in the fineness of its production but also in its ability to withstand the test of time. ABS plastic, due to its inherent physical properties, makes models made with it perform excellently in terms of durability. At the same time, the characteristics of ABS material also determine that its maintenance is relatively simple, allowing the model to maintain a good condition for a long time, which is crucial for model enthusiasts and professionals alike.

- Good Impact Resistance: ABS has a certain degree of toughness, making it more resistant to accidental bumps and drops compared to some brittle materials, and less prone to cracking or severe damage.

- Good Abrasion Resistance: The surface of ABS is relatively hard, and it is not prone to obvious scratches or wear during normal display and handling, which can maintain the appearance quality of the model.

- Easy to Clean: The surface of ABS is smooth and does not easily absorb dust and stains, making it relatively easy to clean. Usually, wiping with a soft cloth can remove surface dirt.

- Certain Weather Resistance: Although prolonged exposure to strong ultraviolet light may cause ABS to age and discolor, ABS models can maintain stability and color for a long time in indoor environments.

Performance of ABS plastic sheet

| Feature | Description | Main Application in Modeling |

|---|---|---|

| Easy to Process | Can be cut, carved, thermoformed; flexible shaping. | Detail Making, Body Shaping |

| Diverse Joining | Can be glued, heat-welded, mechanically fixed; easy assembly. | Structure Building, Part Connection |

| Good Surface Finish | Easy to sand, paint; rich color and texture expression. | Model Painting, Visual Effects |

| Good Durability | Impact-resistant, wear-resistant; not easily damaged. | Long-term Display, Playable Models |

Visual Effects of ABS Products

Through different surface treatment processes, ABS models can present a variety of textures such as matte, glossy, and metallic, meeting the needs of various design styles. In addition, the good formability of ABS also means that it can create smooth lines and complex curved surfaces, ultimately presenting expressive and attractive visual effects.

1.Color Performance: ABS material is easy to color and can achieve bright, full, and lasting color effects.

2.Surface Texture: Through different surface treatment processes, the surface of ABS can present a variety of textures such as glossy, matte, or textured.

3.Detail Representation: ABS material has high molding precision and can clearly display various details of the model design.

4.Overall Appearance: ABS plastic often gives model products a simple and modern overall visual style.

Conclusion

In conclusion, ABS plastic sheets occupy an important position in the field of model making due to their excellent comprehensive performance. They are not only easy to process and connect, but also can achieve diverse surface effects and good durability. Whether building the main body, creating details, or pursuing the final visual presentation, ABS can provide reliable support.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!