Injection-molded short lenses are widely used in miniaturized and lightweight optical systems. Its core strengths lie in design freedom and mass production capabilities.

This technology is not flawless, with optical properties and material limitations being its main challenges. This article will focus on the advantages and disadvantages of injection-molded short lenses in an attempt to provide a concise analysis.

In which scenarios does injection-molded short lenses stand out?

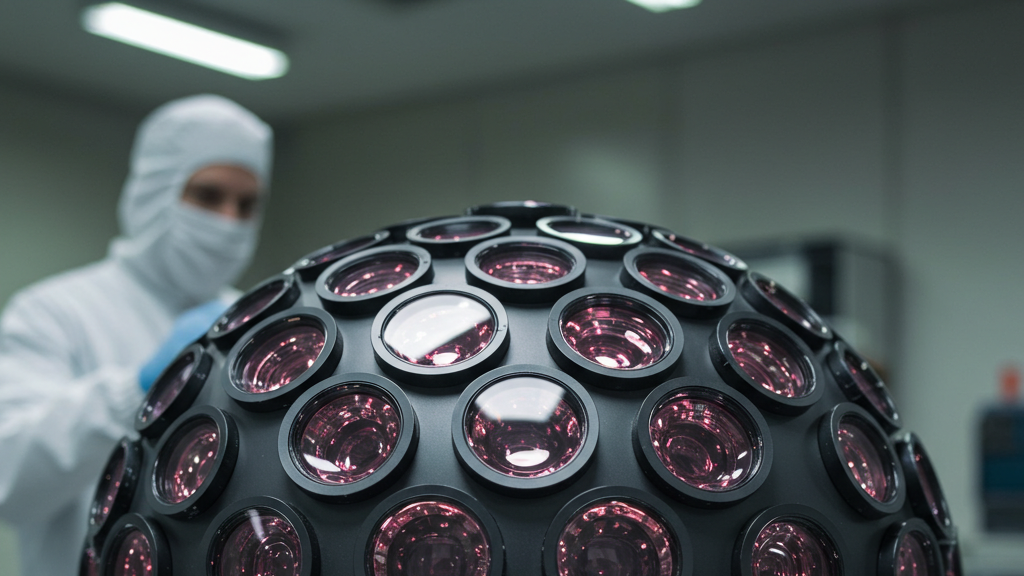

Injection-molded short lenses are compact and have an optical lens made of plastic at the core, which can be flexibly designed. The injection molding process realizes high-precision manufacturing, taking into account miniaturization, lightweight, and cost-effectiveness, and meets the needs of diverse application scenarios.

- Consumer electronics: Among miniaturized devices, injection-molded short lenses are the first choice due to their light weight and cost advantages.

- Automotive: In automotive applications, injection-molded short lenses are favored for their durability and mass production capabilities.

- Medical devices: In the medical field, injection-molded short lenses meet the need for miniaturization with precision and design flexibility.

What are the performance differences between glass lenses and injection-molded short lenses?

Glass lenses offer advantages in terms of optical performance and stability, making them suitable for high-end optical applications. Injection-molded short lenses offer advantages in terms of cost, production, and design flexibility for high-volume production applications such as consumer electronics.

- Optical performance: Glass lenses offer better image quality and stability, while injection-molded lenses offer superior cost and lightweight.

- Material Properties: Glass lenses are durable but difficult to process, while injection molded lenses are light and easy to process but less durable.

- Design flexibility: Injection molding technology enables complex shapes and is far more flexible than glass lenses.

- Cost and Production: Injection-molded short lenses offer significant cost and efficiency advantages in large-scale production.

What is the impact of the material on the performance and cost of injection-molded short lenses?

Material selection is a key factor in the design of injection-molded short lenses. Consider factors such as the optical properties, mechanical properties, thermal properties, environmental adaptability, and cost of the material. Choosing the right material can optimize the performance of injection molded short lenses and reduce costs.

- Thermal properties: The coefficient of thermal expansion of the material affects the stability of the lens under temperature changes.

- Environmental adaptability: The chemical resistance and UV resistance of the material determine the reliability of the lens in different environments.

- Raw material cost: The raw material cost of different plastic materials varies significantly, which directly affects the manufacturing cost of the lens.

- Processing cost: The processing difficulty and formability of the material affect the production cost and efficiency.

Comprehensive performance and cost evaluation form

| Material Name | Optical Properties (Refractive Index/Dispersion) | Thermal Properties (Coefficient of Thermal Expansion) | Mechanical Properties (Hardness/Strength) | Cost (Relative) | Applicable Scenarios | Overall Evaluation |

|---|---|---|---|---|---|---|

| Polycarbonate (PC) | 1.586 / Medium | Medium | Medium | Medium | Consumer electronics, automotive | Good overall performance, moderate cost |

| Cyclic Olefin Copolymer (COC) | 1.53 / Low | Low | Medium | High | Precision optics, medical | Excellent optical performance, high cost |

| Polymethyl Methacrylate (PMMA) | 1.49 / Medium | Medium | Medium | Low | Consumer electronics, lighting | Low cost, average optical performance |

| Polyolefin (PO) | 1.51 / Low | Low | Low | Very low | Packaging, lighting | Very low cost, limited optical performance |

Injection-molded short lenses ensure stability for long-term use

Injection molded short lenses have the advantages of flexible design, low cost and strong mass production capacity, and have been widely used in consumer electronics, automotive industry, medical equipment and other fields. However, the stability of long-term use is a key factor affecting its application range and longevity.

1.Design optimization: Improve lens performance by optimizing structure and coating to reduce thermal stress and improve mechanical stability.

2.Production process control: Precise injection molding and strict quality inspection are the key to ensuring the quality and stability of lenses.

3.Environmental Suitability Testing: Verify the reliability of the lens under various conditions by simulating real-world environmental testing.

4.Long-term monitoring and maintenance: Regular inspection and maintenance to find and solve problems in time and extend the service life of the lens.

conclusion

Material selection is crucial, and stable optical plastics are the foundation. Design optimization reduces thermal stress and improves mechanical stability. The production process control ensures the high quality of the lenses. Environmental suitability tests verify the reliability of the lens. Long-term monitoring and maintenance extend the life of the lens.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!