Introduction

In the field of silicone rubber injection molding, we know that every project begins with a clear definition of requirements. Through thorough communication and professional analysis, we help clients quickly identify the most suitable processes and materials. The right first step determines whether cooperation proceeds efficiently and smoothly.

We deliver not only products but also a complete set of effective solutions. From design to production, our team ensures that every stage meets standards, minimizing risks and costs. Working with us means gaining a reliable long-term partner.

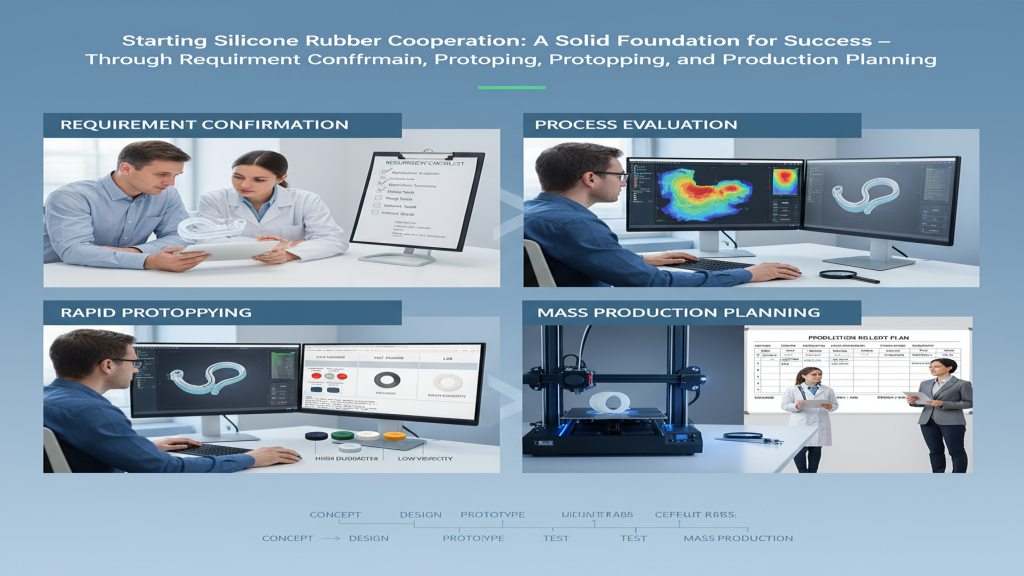

How Do You Start Silicone Rubber Cooperation?

When launching silicone rubber product cooperation, clarifying requirements and design specifications is critical. Based on drawings or samples, we develop a detailed project plan. Clear preparation in the early stage provides a solid foundation for subsequent process development.

- Requirement Confirmation: The first step is to align on design needs and application scenarios.

- Process Evaluation: We create suitable molding solutions based on silicone rubber grades.

- Rapid Prototyping: Sample testing ensures expectations are met.

- Mass Production Planning: Feasibility and cost control are defined for scaling.

😊 A solid beginning ensures successful cooperation.

What Materials Do You Need to Prepare?

Before cooperation, it is essential to provide clear drawings and performance requirements. Our team uses mold flow analysis and material compatibility testing to help mitigate risks. Complete project input significantly improves execution efficiency.

- Technical Drawings: Ensure feasibility and precision of the design.

- Material Selection: Clients specify physical properties and usage environment.

- Quality Standards: Align inspection and delivery benchmarks.

- Sample Comparison: Existing products can be shared for improvement or optimization.

📌 The completeness of materials directly impacts project efficiency.

How Do We Ensure Smooth Cooperation?

Once projects enter execution, we rely on strict processes and quality controls to ensure success. With advanced equipment and an experienced team, we guarantee stability from prototyping to mass production. Comprehensive management allows clients to focus on their markets and applications.

- Project Management: Dedicated engineers provide one-to-one communication.

- Risk Control: Process optimization reduces defect rates.

- Quality Tracking: Batch consistency is ensured through inspections.

- Delivery Commitment: Timely supply is secured within agreed schedules.

✅ A streamlined process saves clients time and cost.

Cooperation Workflow

| Stage | Our Company | Industry Standard | Client Benefit | Risk Control |

|---|---|---|---|---|

| Requirement Check | Fast Response | Slow Communication | Saves Time | Avoids Delays |

| Process Evaluation | Mold Flow Analysis | Experience-Based | Higher Accuracy | Reduced Risks |

| Prototyping Cycle | 3–5 Days | 7–10 Days | Faster Launch | Market Advantage |

| Quality Control | Full Tracking | Random Sampling | Reliable Supply | Fewer Defects |

Expanding Application Value

Silicone rubber products are widely used in consumer goods, healthcare, automotive, and industrial sectors. Through flexible design and processing, we ensure optimal performance across diverse applications. The versatility of silicone rubber provides long-term cooperation value.

1.Medical Applications: Meets biocompatibility and safety standards.

2.Automotive Components: Withstands high temperature and sealing requirements.

3.Electronic Accessories: Provides insulation and durability.

4.Industrial Equipment: Enhances pressure resistance and wear performance.

Conclusion

Starting silicone rubber cooperation with us is a systematic and efficient process. From requirement confirmation to final delivery, we maintain rigorous standards and transparent workflows. Our goal is to help clients achieve stable and rapid breakthroughs in their markets. With professional service and ongoing support, we are the injection molding partner you can trust.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!