Introduction

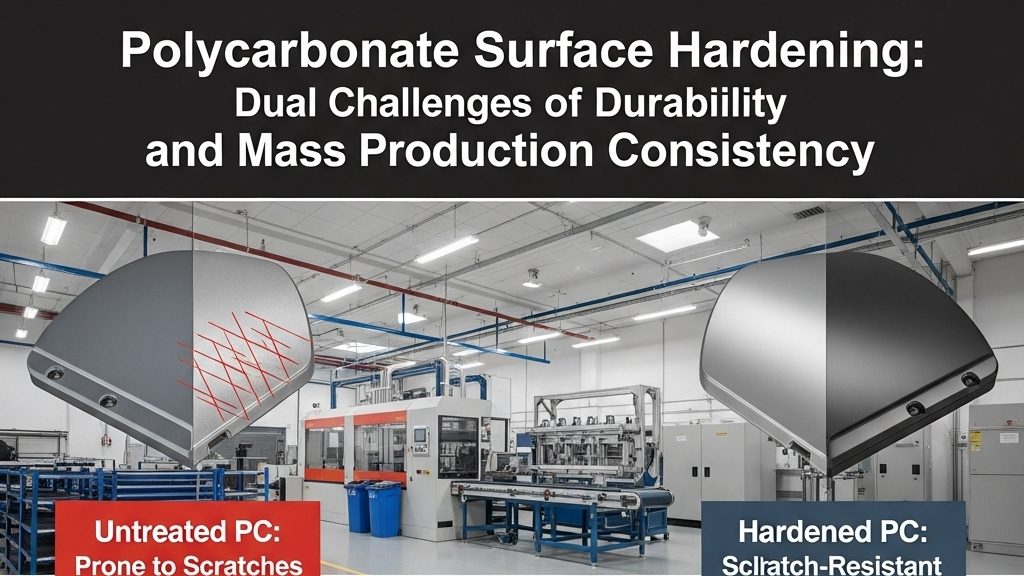

Polycarbonate (PC) is widely used in injection-molded products for its outstanding optical clarity and impact resistance. However, its native surface is prone to scratches, especially in high-usage applications such as automotive panels and electronic lenses. Enhancing surface durability through hardening has become a key industry focus.

Although current surface hardening technologies like coating, sputtering, and UV curing are relatively mature, they still face challenges with processing temperature, coating uniformity, and mass production consistency. This means the ability to replicate surface hardening results consistently at scale is critical for commercialization.

What is the hardness limit?

For PC materials, increasing surface hardness must not compromise toughness. Most common coatings offer hardness between 2H and 4H, while pushing to 6H or higher risks adhesion loss and cracking. A multi-layer gradient structure could be a breakthrough direction.

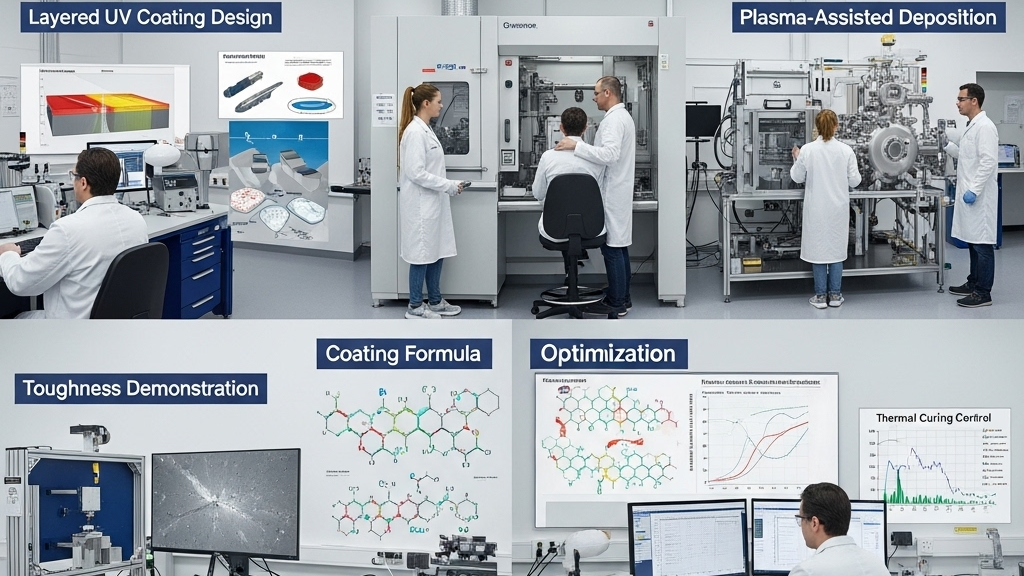

- Coating formula optimization: Adjusting crosslinkers helps balance hardness and flexibility.

- Layered UV coating design: Top layer hardness with bottom layer impact absorption.

- Plasma-assisted deposition: Nanocoatings enhance hardness while managing stress.

- Thermal curing control: Precise temperature management ensures uniform curing.

💡 Hardness isn't just about higher values—material compatibility matters more.

How to improve coating adhesion?

As hardness increases, adhesion becomes a bottleneck. Smooth PC surfaces often cause coating delamination or cracking. Matching pretreatment, coating chemistry, and thermal curing is crucial.

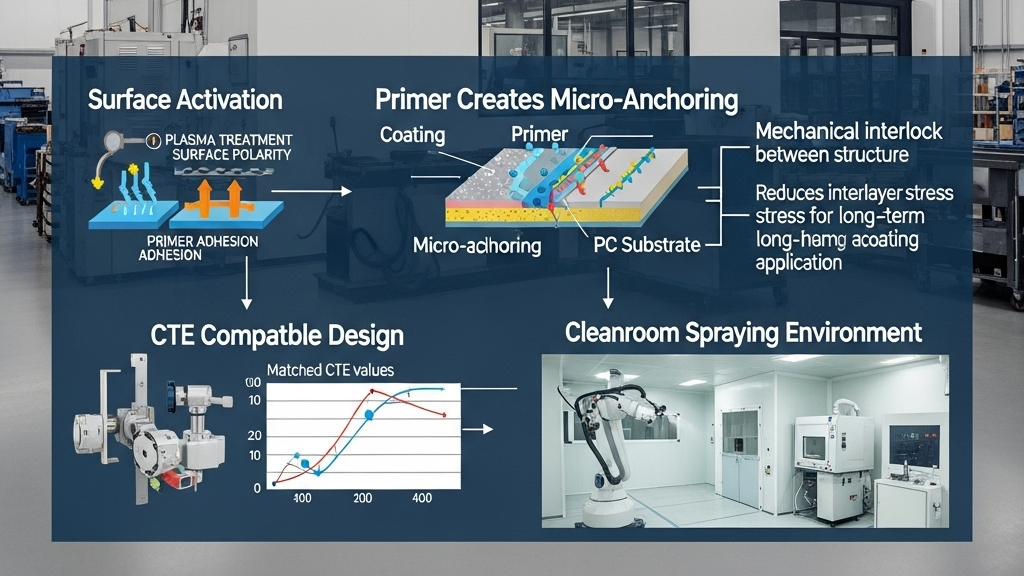

- Surface activation: Plasma or flame treatment increases surface polarity.

- Primer creates micro-anchoring: Mechanical interlock improves bonding.

- CTE compatibility design: Reduces interlayer stress and cracking.

- Cleanroom spraying environment: Prevents adhesion failures from dust.

🧪 Adhesion strength is the backbone of the entire coating system.

Can transparency be maintained?

Improving hardness often reduces light transmittance, especially with large-particle inorganic coatings that scatter light. Balancing durability and visual clarity requires careful formulation and process control.

- Nanoparticle dispersion control: Particles smaller than visible wavelengths avoid scattering.

- Surface tension tuning: Smooth leveling reduces orange peel.

- Multi-layer optical match: Combines anti-reflective and scratch resistance.

- Modified transparent resin matrix: Maintains gloss and hardness.

🌈 Transparency isn't a sacrifice—it’s a controllable design variable.

Comparative Analysis of Processing Methods

| Process Type | Hardness | Adhesion | Transparency | Temp Tolerance | Equipment Cost | Stability | Line Compatibility | Estimated Cost |

|---|---|---|---|---|---|---|---|---|

| UV Coating | 2H~4H | Medium | High | Moderate | Low | High | High | Medium |

| Thermally Cured Silica | 5H~6H | High | Medium | High | High | Medium | Medium | High |

| Sputtered Inorganic Film | 6H+ | Medium | High | High | High | Medium | Low | High |

| Nano Composite Coating | 3H~6H | High | High | Moderate-High | Medium | Medium-High | Medium | Medium |

Emerging Surface Technologies

With rising demands for both aesthetic and functional performance in PC parts, several new surface hardening technologies are gaining attention—such as plasma co-deposition, UV-assisted polymerization, and molecular-level interface bonding. Though still in early stages, these techniques show promising performance and automation compatibility.

1.Plasma Co-Deposition: Breaks the adhesion barrier with innovative bonding.

2.UV-Induced Surface Polymerization: Rapid curing with strong bonding.

3.Dynamic Spray Systems: Uniform application and material efficiency.

4.Smart Closed-Loop Monitoring: Real-time visual control of hardening process.

Conclusion

PC surface hardening is evolving along multiple technological paths to satisfy both optical appeal and physical durability. In mass production, balancing cost, yield, and stability is essential. Future innovation will rely not just on individual breakthroughs, but on system-level process integration. With advanced materials and engineering coordination, the limits of PC surface hardening will continue to expand.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!