In harsh environments, the equipment enclosure is a critical barrier to ensure its stable operation. Impact-resistant plastics, due to their unique energy absorption characteristics, are an ideal choice for demanding environments. When facing challenges such as extreme temperature variations, corrosion, or impacts, selecting the appropriate impact-resistant plastic is of paramount importance.

Different harsh environments place different performance requirements on plastic enclosures. Low temperatures can lead to material embrittlement, while high temperatures or humidity accelerate aging. The nature of the impact load also directly affects the material's impact resistance performance.

What are the key performance requirements for plastics in harsh environments?

Whether it's the pressure of the deep sea, the scorching heat of the desert, or the chemical corrosion of industrial environments, each harsh environment places stringent demands on the strength, toughness, stability, and durability of plastics. Understanding these key properties is the first step in selecting the right plastic.

- Resistance to Extreme Temperatures: Plastics must maintain stable performance under extreme temperature variations.

- Chemical Corrosion Resistance: Plastics should be able to resist the corrosive effects of various chemical substances.

- Impact Strength: Plastics need to have the ability to absorb and dissipate impact energy.

- Weather Resistance/Anti-Aging: Plastics should be able to resist the effects of natural environmental factors over the long term.

What are the property differences of mainstream plastics in harsh environments?

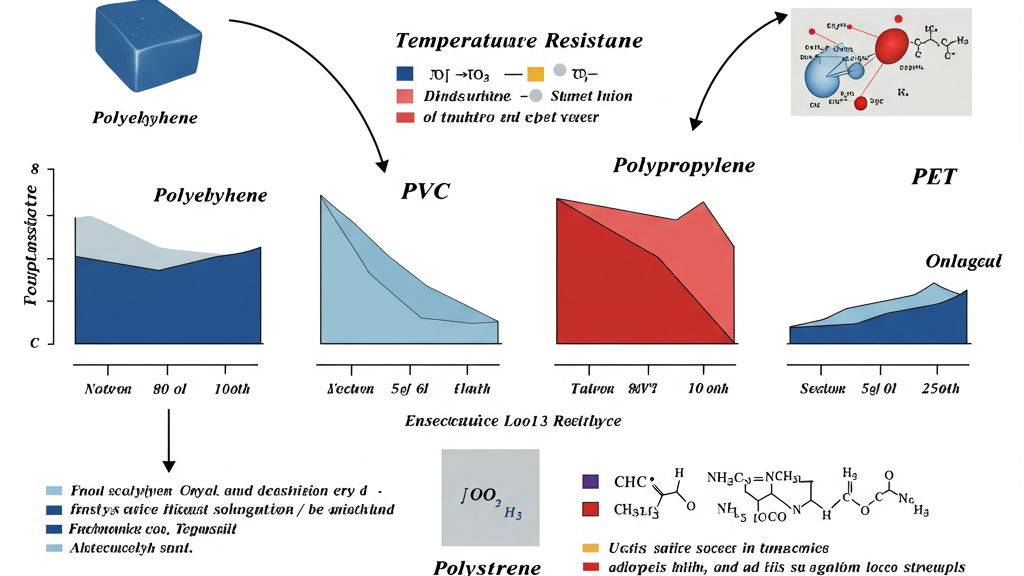

Different molecular structures and chemical compositions give mainstream plastics distinct differences in temperature resistance, chemical resistance, and mechanical strength. In-depth analysis of these property differences can help us better predict and evaluate their performance under extreme conditions.

- Temperature Resistance: Different plastics exhibit significantly different performance characteristics at extreme temperatures.

- Chemical Corrosion Resistance: The ability of various plastics to resist chemical attack varies.

- Mechanical Strength and Toughness: Mainstream plastics differ in terms of strength and impact resistance.

- Weather Resistance and Anti-Aging: The ability of plastics to resist long-term environmental influences varies greatly.

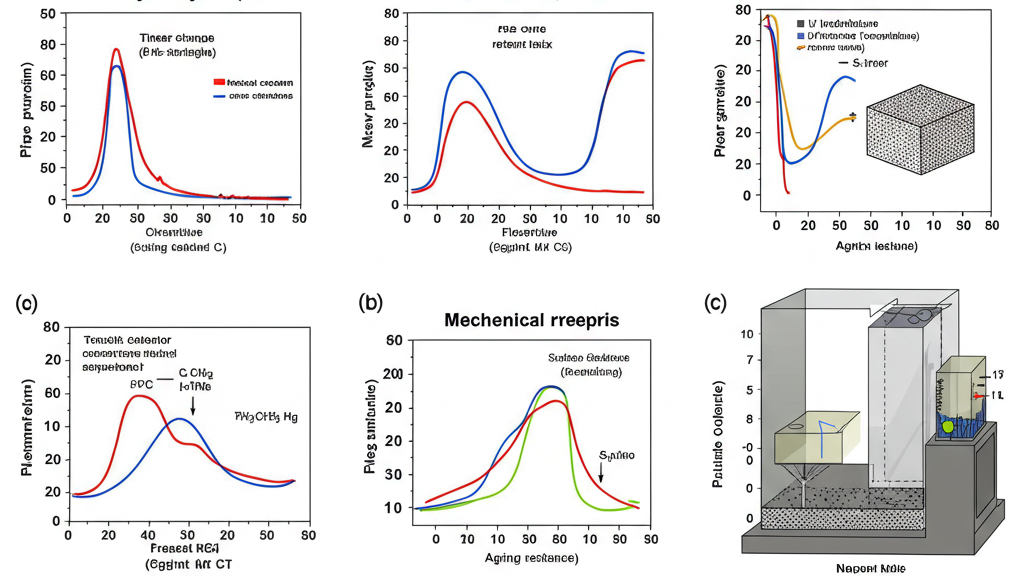

How does plastic modification enhance environmental adaptability?

To enable plastic enclosures to better perform their protective role in harsh environments, engineers are constantly exploring the mysteries of material modification. By cleverly adjusting the composition and structure of plastics, we can significantly enhance their resistance to heat, cold, corrosion, and aging.

- Enhance Resistance to Extreme Temperatures: Modification can broaden the stable operating temperature range of plastics in extreme temperature conditions.

- Improve Chemical Corrosion Resistance: Modification can enhance the ability of plastics to resist chemical attack.

- Increase Impact Strength: Modification significantly improves the ability of plastics to withstand mechanical impacts.

- Improve Weather Resistance and Anti-Aging Properties: Modification effectively delays aging caused by environmental factors.

Influence of Modification Methods on the Adaptability of Plastics

| Modification Method | Main Effect | Impact on Extreme Temperature Resistance | Impact on Chemical Corrosion Resistance | Impact on Impact Strength | Impact on Weathering/Aging Resistance | Example Plastics |

|---|---|---|---|---|---|---|

| Toughening Agent | Improve Impact Strength & Toughness | May slightly decrease high temp strength, improve low temp toughness | Generally no significant impact | Significantly increase | Generally no significant impact | PC, ABS, PA |

| Fiber Reinforcement | Significantly Increase Strength, Stiffness & Heat Resistance | Significantly increase high temp strength, may decrease low temp toughness | May improve resistance to some chemicals | Significantly increase | May improve wear resistance | PA, PC, PEEK |

| Blending Modification | Combine Advantages of Multiple Plastics | Performance depends on components, can balance temp resistance | Performance depends on components, can introduce chemical resistance | Performance depends on components, can increase impact strength | Performance depends on components, can improve weathering resistance | PC/ABS, PA/ABS |

| Weathering Additives | Improve Resistance to UV & Other Environmental Factors | Generally no significant impact | Generally no significant impact | May slightly decrease | Significantly increase | PC, ABS, PA |

Selecting the Right Plastic Based on Environment

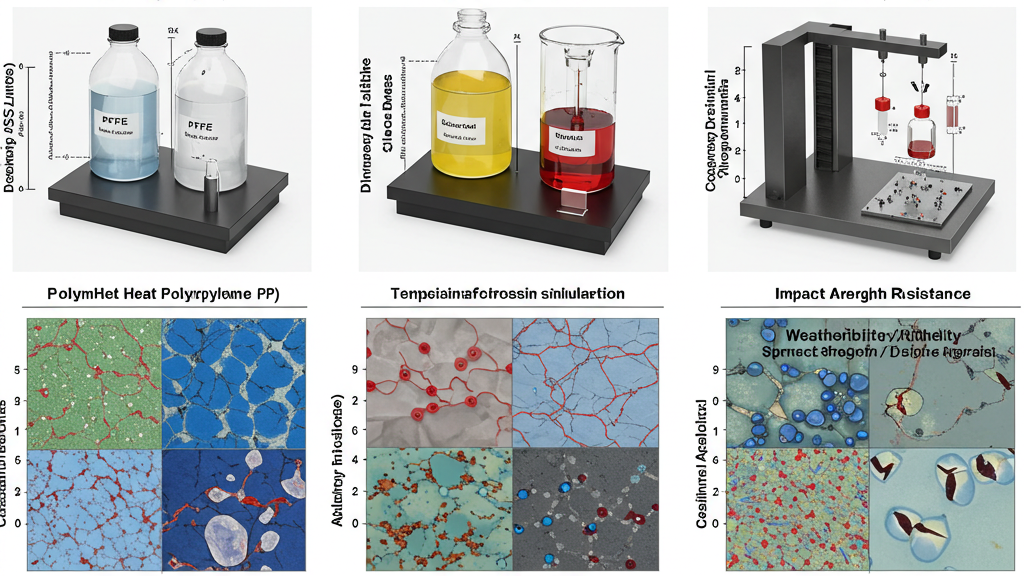

Choosing a plastic enclosure for a harsh environment requires careful consideration. The primary task is to identify the specific characteristics of the application environment, such as extreme temperatures, chemical corrosion, or mechanical impacts. Subsequently, it is necessary to evaluate the key performance characteristics of different plastics in these environments. The ultimate goal is to weigh material properties against modification options, and select the best plastic that can provide reliable and durable protection in a specific harsh environment.

1.Identify Environmental Stresses: Identifying the primary harsh factors in the application environment is the first step in selecting a plastic.

2.Match Plastic Properties: Matching the plastic's resistance properties to the environmental stresses is crucial.

3.Consider Long-Term Performance: Long-term performance stability is a key factor that must be considered when selecting a plastic.

4.Weigh Cost Feasibility: While meeting performance requirements, it is also necessary to weigh cost and feasibility.

Conclusion

The selection of impact-resistant plastic enclosures for harsh environments is critical. It is necessary to clarify the environment's key performance requirements for plastics, such as temperature resistance, chemical corrosion resistance, and impact resistance. Mainstream plastics differ in these properties, and modification techniques can effectively enhance their environmental adaptability. The final selection should be based on various factors such as environmental stresses, long-term performance, and cost to ensure optimal protection for the equipment.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!