Introduction

Transparent ABS requires high processing precision during injection molding, especially when balancing optical properties with structural integrity. The balance between transparency and mechanical performance is one of the most critical challenges in production.

In industrial applications, transparent ABS must deliver flawless appearance while maintaining mechanical strength, raising higher standards for mold design and process control. Manufacturers must optimize raw materials, molding parameters, and inspection methods to ensure products meet market demands.

How to Prevent Silver Streaks and Flow Marks in Transparent ABS?

During transparent ABS injection molding, silver streaks and flow marks often affect appearance and reduce customer confidence. Controlling melt flow and mold venting is the core method to minimize such defects.

- Mold Temperature Control: Balanced mold temperature reduces weld lines.

- Material Drying: Ensures fully dried resin to prevent bubbles.

- Gate Design Optimization: Proper gate position and size improve melt flow.

- Venting System: Effective venting channels reduce trapped gas.

😊 Optimized process control helps improve surface appearance of transparent ABS parts

How to Control Shrinkage and Warpage in Transparent ABS?

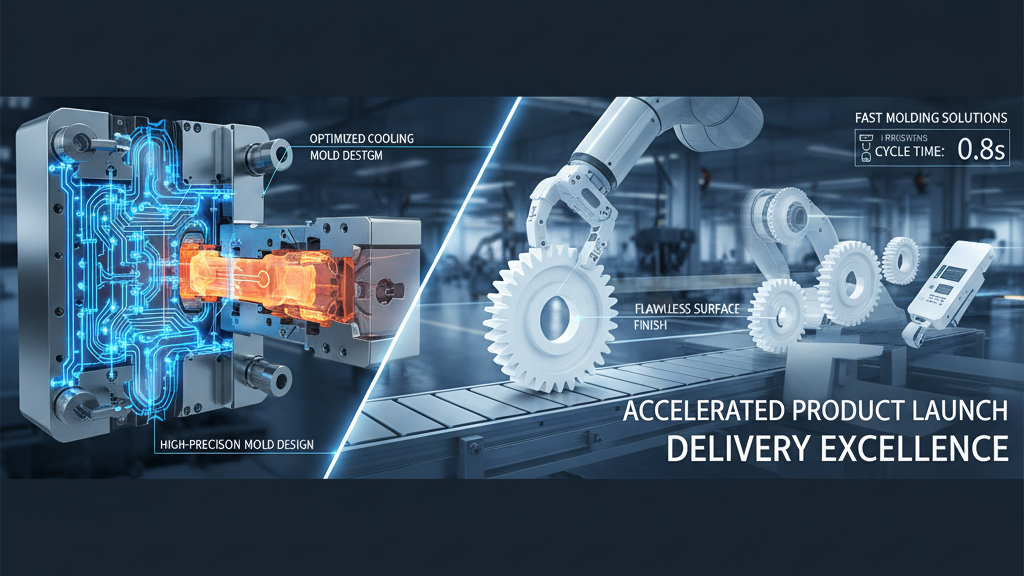

Transparent ABS tends to show dimensional instability and warpage during cooling shrinkage. Precise control of cooling time and mold structure is the key to reducing shrinkage and deformation.

- Uniform Cooling: Prevents localized stress caused by uneven cooling.

- Mold Design: Proper design reduces stress concentration.

- Uniform Wall Thickness: Minimizes internal stress and shrinkage.

- Process Parameter Optimization: Appropriate injection pressure and speed reduce dimensional variation.

🔧 Dimensional stability relies on proper process and mold optimization

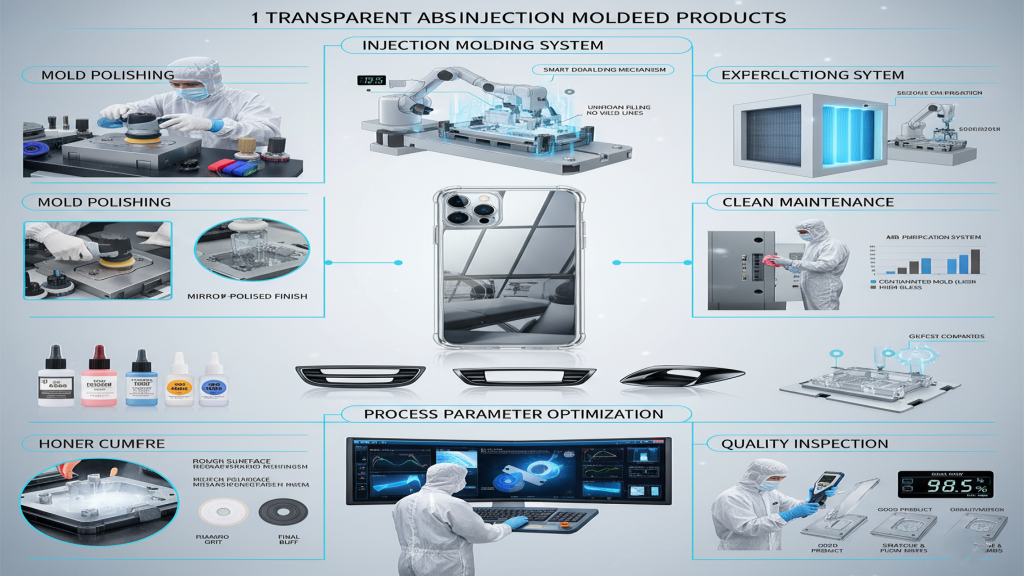

How to Improve the Surface Gloss of Transparent ABS?

Transparent ABS products require excellent surface gloss, where even minor flaws can affect appearance. Mold surface polishing and stable process control directly determine gloss quality.

- Mold Polishing: Mirror finishing significantly improves surface gloss.

- Injection Pressure: Proper pressure ensures complete filling.

- Demolding Process: Smart design prevents scratches during ejection.

- Clean Maintenance: Ensures both molds and environment remain free of contaminants.

✨ Surface gloss is the key for transparent ABS parts to win in the market

Comparison of Common Transparent ABS Issues and Solutions

| Challenge Type | Silver Streaks & Flow Marks | Shrinkage & Warpage | Poor Gloss | Dimensional Instability |

|---|---|---|---|---|

| Key Cause | Poor venting | Uneven cooling | Rough mold | Wall thickness variation |

| Solution | Optimize venting | Controlled cooling | Mold polishing | Uniform thickness |

| Process Focus | Drying & gate design | Mold structure | Injection pressure | Parameter tuning |

| Improvement | Better appearance | Higher precision | Visual quality | Stable performance |

Technique Expansion

Beyond conventional process control, manufacturers can integrate new materials and automation systems to enhance competitiveness of transparent ABS products. Smart production and online monitoring enable faster detection and resolution of defects.

1.Automated Inspection: Real-time detection of surface defects.

2.Modified Materials: Enhances weather resistance and transparency.

3.Smart Mold Temperature Control: Enables precise heat management.

4.Process Data Tracking: Leverages big data to ensure consistency.

Conclusion

The production of transparent ABS injection parts requires balancing aesthetics, dimensional accuracy, and performance. Through scientific process optimization and smart manufacturing, companies can overcome key challenges and enhance competitiveness.As high-end markets demand more, continuous improvements in mold technology and processing methods become essential. Ultimately, only precision combined with efficiency ensures transparent ABS products stand out in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!